Secondary Composite Telescoping Outriggers

A technology of telescopic outriggers and lead screws, which is applied in the direction of supporting machines, machine tables/brackets, belts/chains/gears, etc., which can solve the problem of excessive axial installation space and size of the first-level lead screw outriggers, and increased center of gravity of vehicle-mounted instruments. Advanced problems, to achieve the effect of compact structure, easy operation, and guaranteed center of gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

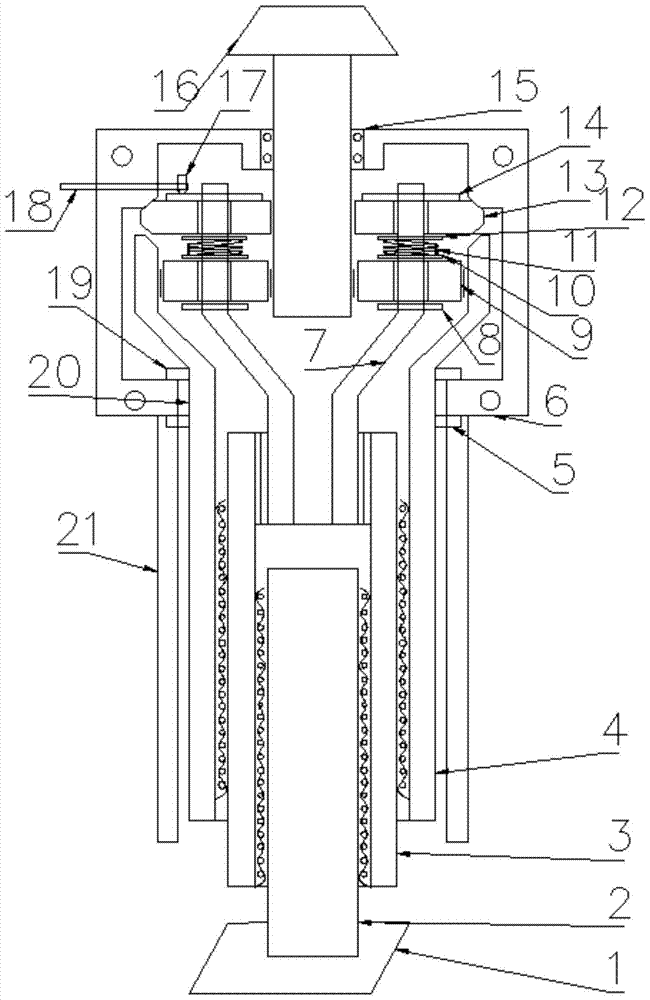

[0016] The specific embodiment of the present invention will be described with reference to the accompanying drawings.

[0017] Such as figure 1 As shown, the secondary composite telescopic outrigger, the supporting foot plate 1 is installed on the lower end of the primary screw 2, the primary screw 2 is installed on the inner ring of the secondary screw 3, the outer ring of the secondary screw 3 is connected to the ring gear 4, The ring gear 4 is connected to the support 6 through the lower ring gear bearing 5 and the upper ring gear bearing 19; there are tapered teeth in the support 6;

[0018] The inner ring of the secondary lead screw 3 has a spline, which is connected with the outer spline of the lower half of the planet carrier 7, and the lower half of the planet carrier 7 is fixedly connected with the upper end of the primary lead screw 2;

[0019] The planetary gear 9 is installed on the top of the planetary carrier 7 through the lower thrust bearing 8 and the upper t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com