Revolution cabinet real-time inventory verification and positioning system

A positioning system and rotary cabinet technology, applied in the field of rotary cabinet disk storage and positioning system, can solve the problems of long time, waste of time and resources, inconvenient operation, etc., and achieve the effect of small power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

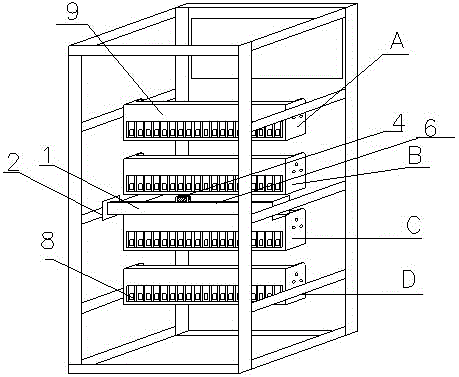

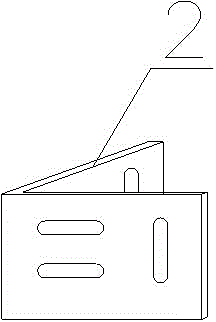

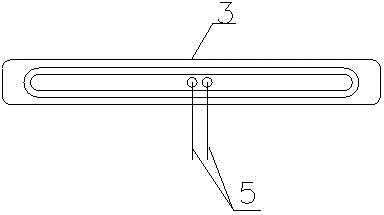

[0022] like Figure 1-4 As shown, the present invention discloses a real-time inventory and positioning system for a revolving cabinet. The front panel of the revolving cabinet is provided with an access window, and an RFID antenna packaging box 6 is installed between the horizontal columns on both sides of the revolving cabinet. The RFID antenna package An RFID antenna 3 is arranged in the box 6, and a feeder 5 is connected to the RFID antenna 3, and the feeder 5 is connected to the reader 4 arranged on the RFID antenna packaging box 6;

[0023] There is a transmission device in the revolving cabinet, and the transmission device drives the bucket plate 9 in the revolving cabinet to move around the RFID antenna 3 along the arc track;

[0024] An electronic tag 8 is provided on the items in the bucket board 9;

[0025] The RFID antenna 3 is corresponding to the access window;

[0026] When the electronic tags 8 of the items in the bucket board 9 correspond to the RFID antenna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com