Six conductor cable

A cable, wire technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

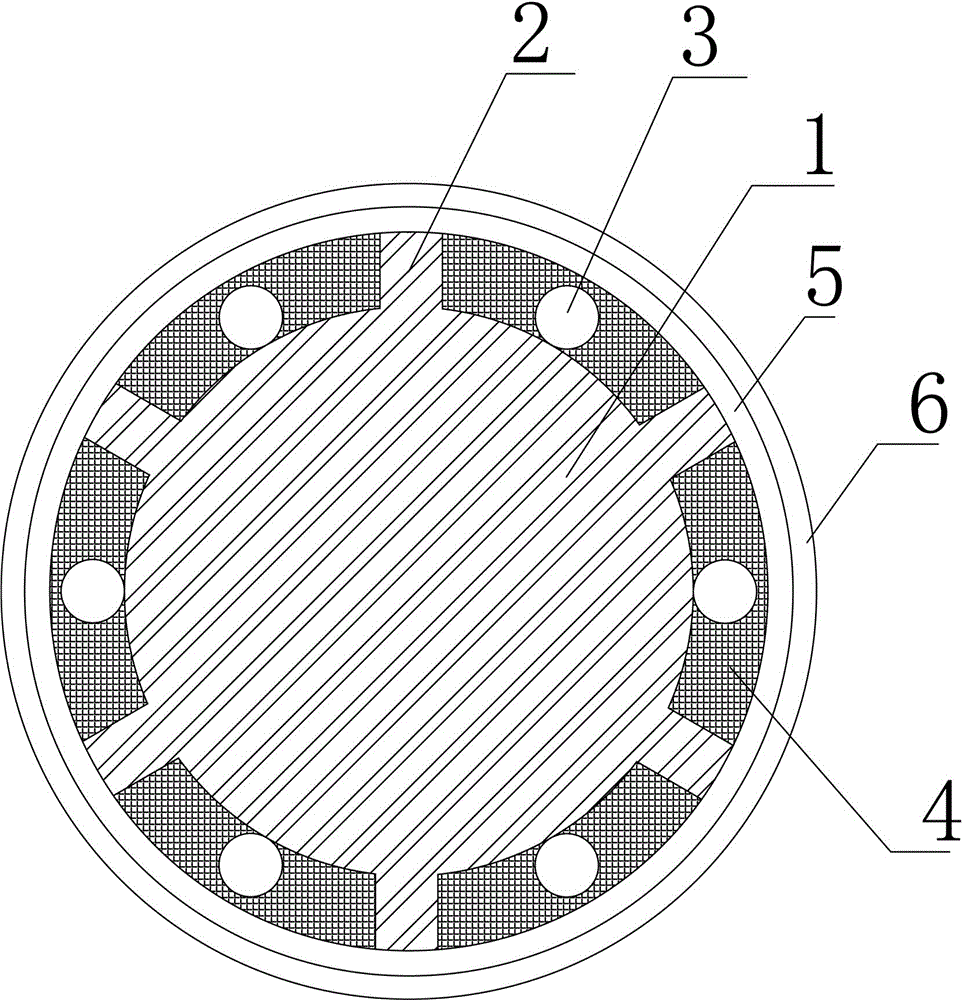

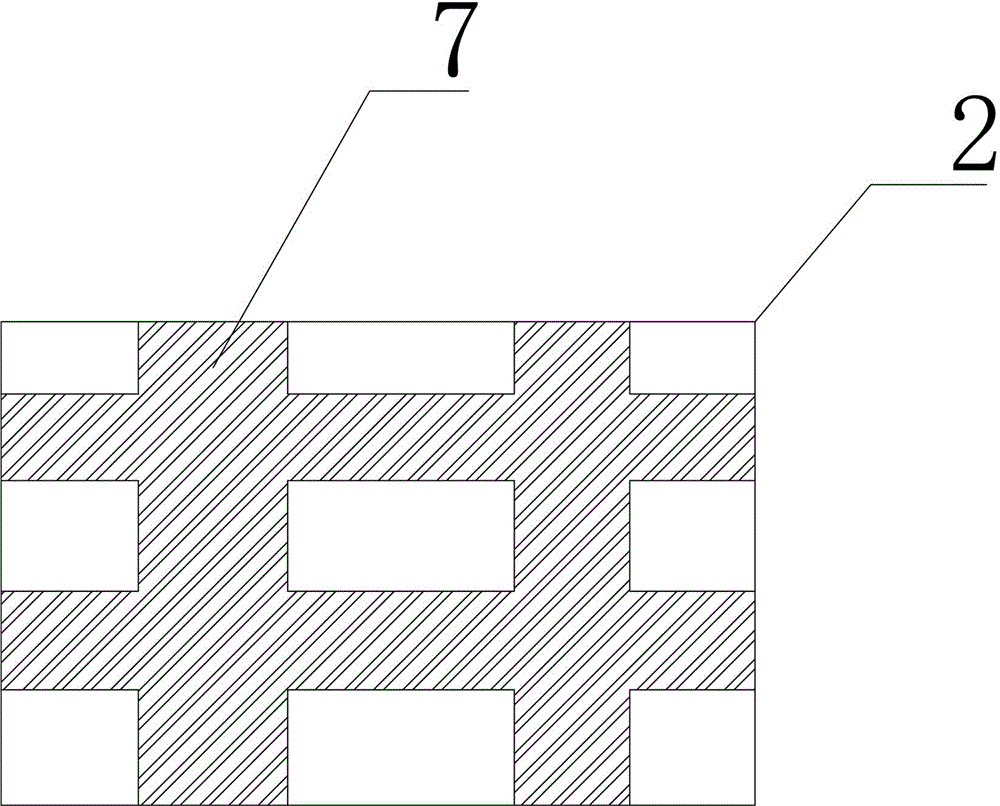

[0015] Such as figure 1 Among them, a six-core cable includes a central layer 1, the cross-sectional center of the central layer 1 is circular, and a plurality of baffles 2 are provided on its central edge, and the six conductors 3 take the central point of the central layer as the center of the circle, and surround the central layer. Distributed in a circle, there is a baffle 2 between adjacent wires 3, the surface of the baffle 2 is provided with protruding ridges 7 intersecting vertically and horizontally, the distance between adjacent wires 3 is more than twice the cross-sectional diameter of the wire 3, and the insulating material 4 is filled Between the adjacent wires 3 and fixed on the baffle 2, the raised ridge 7 on the baffle 2 increases the contact area with the isolation material 4, and wraps the protection tape 5 and the sheath layer outside the isolation material 4 and the wire 3 in sequence 6;

[0016] The material of the central layer 1 is polypropylene; the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com