A kind of non-diffraction brightening prism sheet and display screen

A prism sheet, non-diffraction technology, applied in prisms, instruments, optics, etc., can solve the problems affecting the effect of display dimming and adjusting the light angle, etc., to reduce the difficulty of dimming, reduce mutual extrusion and friction damage, Guaranteed consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

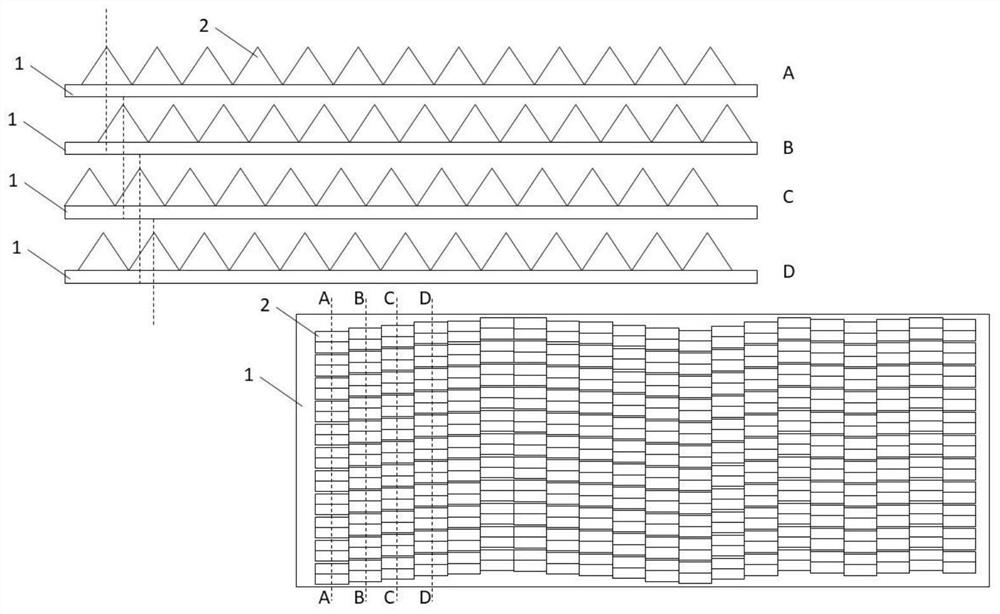

[0029] like Figure 3-4 As shown, a non-diffraction brightness enhancement prism sheet, the prism sheet includes a lower bottom 1 and an upper end 2, the lower bottom 1 is a flat plate, the upper end 2 is located on the upper surface of the lower bottom 1, and is integrally formed with the lower bottom 1 The upper end 2 includes a plurality of elongated convex prisms with a triangular cross-section, so that part of the light propagating upward from the lower bottom 1 is refracted through the prism sheet and emitted from the upper end 2, and a part is totally reflected by the prism from the bottom Bottom 1 shot;

[0030] And the extension directions of the tips of all the prisms of the upper end 2 are all parallel to each other, and the length along the extension direction of the tips of the prisms is defined as the length of the prism. width, the ratio of the length to the width of the prism is 2 to 5:1;

[0031] After extending a prism length along the extension direction o...

Embodiment 2

[0035] like Figure 5 As shown, a method for manufacturing a diffraction-free brightness-enhancing prism sheet is provided, including:

[0036] Step 1, providing a substrate film, the substrate is at least one of polystyrene resin, acrylic resin, polycarbonate resin, or styrene methyl methacrylate resin;

[0037] Step 2, provide a roller 3, the surface of the roller 3 is provided with a shape 4 complementary to the surface structure of the prism sheet, so that when the roller 3 rolls on the surface of the substrate film, a column of prisms can be formed on the surface of the substrate film, and the roller The barrel 3 is a hollow structure, and low-temperature liquid can be injected into it;

[0038] Step 3, heating the substrate film to a predetermined temperature to soften the substrate;

[0039] Step 4, inject low-temperature liquid into the roller 3, and then roll the roller 3 on the surface of the substrate film once, so that a column of prisms is formed on the surface ...

Embodiment 3

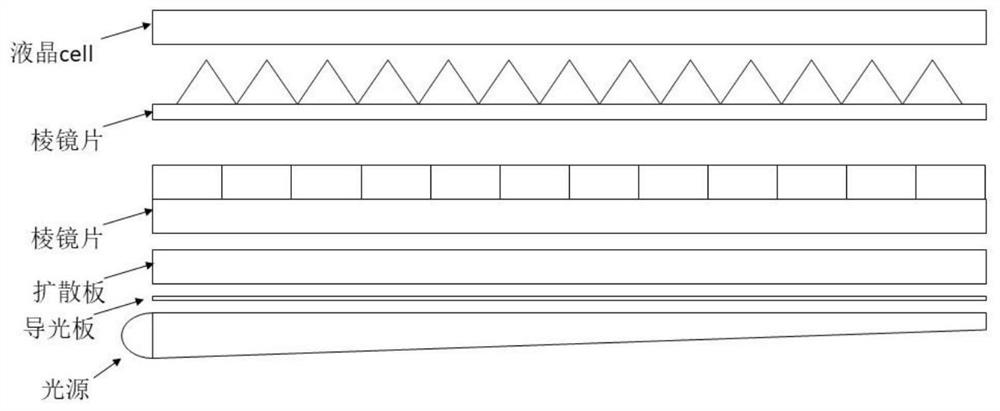

[0042] provide a diffraction-free display such as figure 2 As shown, the display screen has the non-diffraction brightening prism sheet;

[0043] The display has two layers of non-diffractive brightness-enhancing prism sheets arranged perpendicular to each other, and the display also includes:

[0044]Liquid crystal cell, diffuser plate, light guide plate and backlight source; the display screen is provided with liquid crystal cell, first prism sheet, second prism sheet, diffuser plate, light guide plate and backlight source in order from top to bottom.

[0045] The upper end portion 2 of the prism sheet is provided with a hard protective film layer during assembly, and there is no relative displacement between the prism sheet and the hard protective film layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com