Large-size panel backlight assembly structure and assembly method thereof

A technology for assembling structures and backlight structures, which is applied in the direction of assembling printed circuits with electrical components, printed circuits connected with non-printed electrical components, and electrical components, and can solve problems such as damage to flexible printed circuit boards and difficult assembly of backlight structures , to achieve the effect of strengthening the overall structural support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] In order to enable those skilled in the art to understand the purpose of the present invention, preferred embodiments of the present invention are described in detail below in conjunction with the drawings.

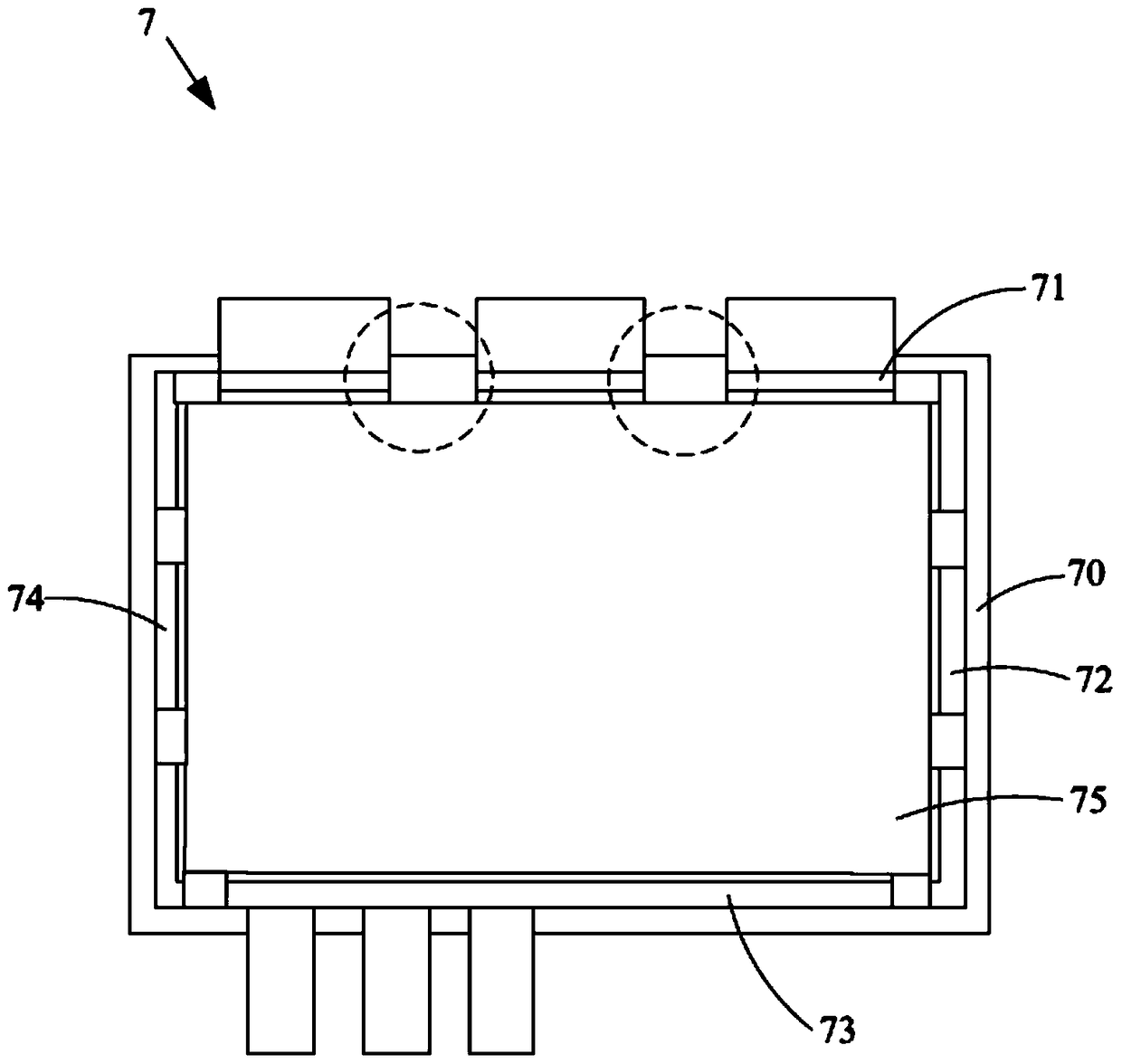

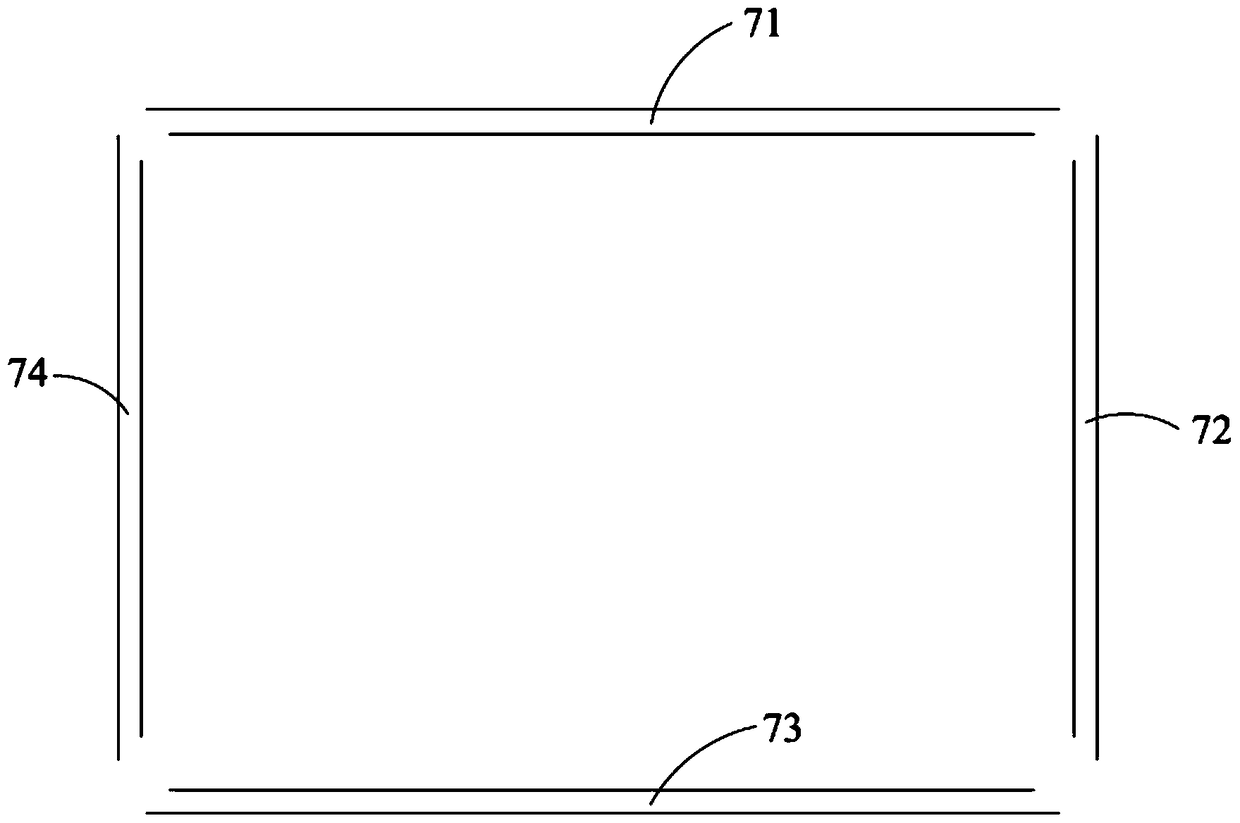

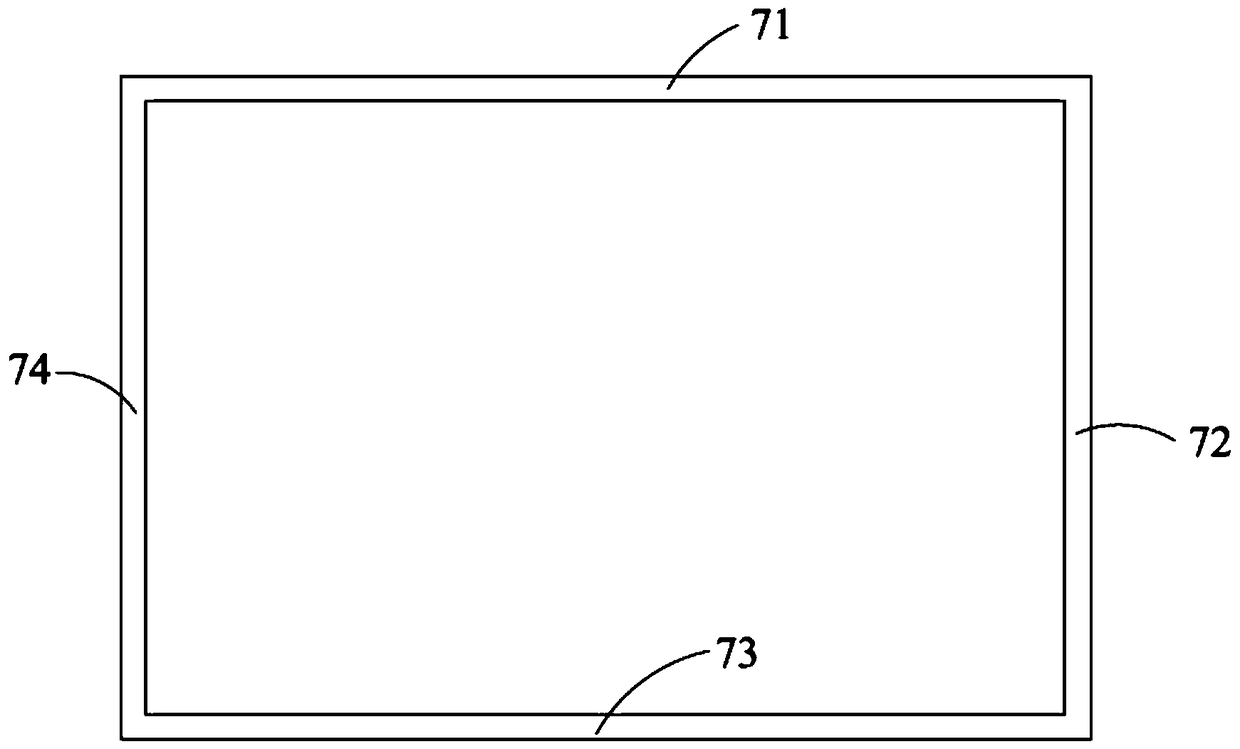

[0065] Please refer to Figure 3 and Figure 4 As shown, the large-size panel backlight assembly structure (1) of the present invention includes a window cover (10), a U-shaped frame (11), a straight frame (12), a first L-shaped frame (13) ), a second L-shaped frame (14) and a backlight structure (15).

[0066] The window cover (10) has a rectangular structure and includes an ink position, which is located on the left, right and lower edges of the window cover (10) and is U-shaped.

[0067] The U-shaped frame (11) is attached to the ink position of the window cover (10).

[0068] The two ends of the one-shaped frame (12) are assembled with the two ends of the U-shaped frame (11) respectively, and form a mouth-shaped frame with the U-shaped frame (11), and the mout...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com