Grinding equipment for end face of casting

A casting and equipment technology, applied in the field of casting end face grinding equipment, can solve the problems of insufficient grinding manpower and low grinding quality, and achieve the effects of improving the end face grinding quality, increasing the grinding speed, and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

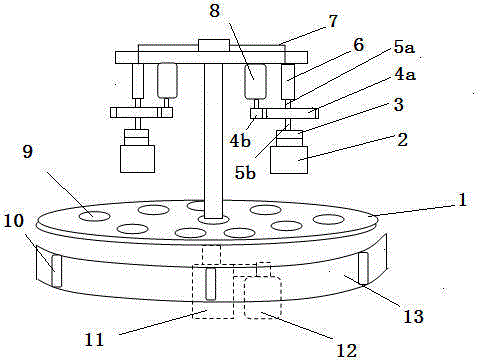

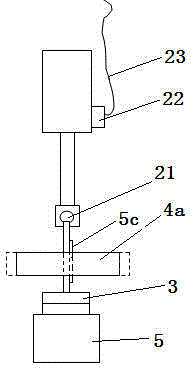

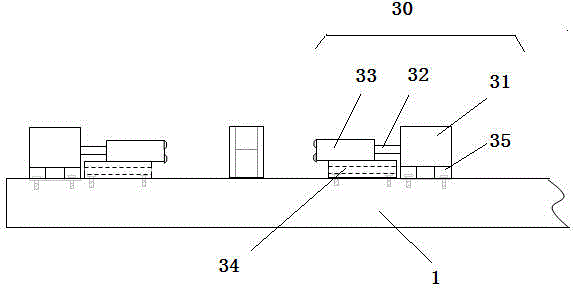

[0009] In order to better understand and implement the technical solution of the present invention, some embodiments of the present invention are provided here. These examples are for better explaining the technical solution of the present invention, and do not constitute any form of limitation to the present invention. Refer to the following figure 1 , figure 2 , image 3 To further illustrate the technical solution of the present invention, in the figure, 1: grinding table, 2: grinding head, 3: counterweight, 4a: central shaft gear, 4b: motor gear, 5a: cylinder rod, 5b: cylinder center Axis, 5c: sliding key, 6: cylinder, 7: air pipe, 8: rotating motor, 9: fixture, 10: heightening intubation, 11: reducer, 12: main motor, 13: fence, 21: ball joint, 22: travel switch, 23: wiring, 30: clamping seat, 31 oil cylinder, 32: oil cylinder rod, 33: clamping head, 34: sliding seat, 35: clamping head.

[0010] The present invention is a technical scheme of casting end face grinding e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com