Adjustable torque tensioning mechanism

A tensioning mechanism and force adjustment technology, which is applied in hand-held tools and manufacturing tools, can solve the problems of complex structure, large volume, and large minimum torque range, and achieve the effect of simple structure and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below with reference to the accompanying drawings.

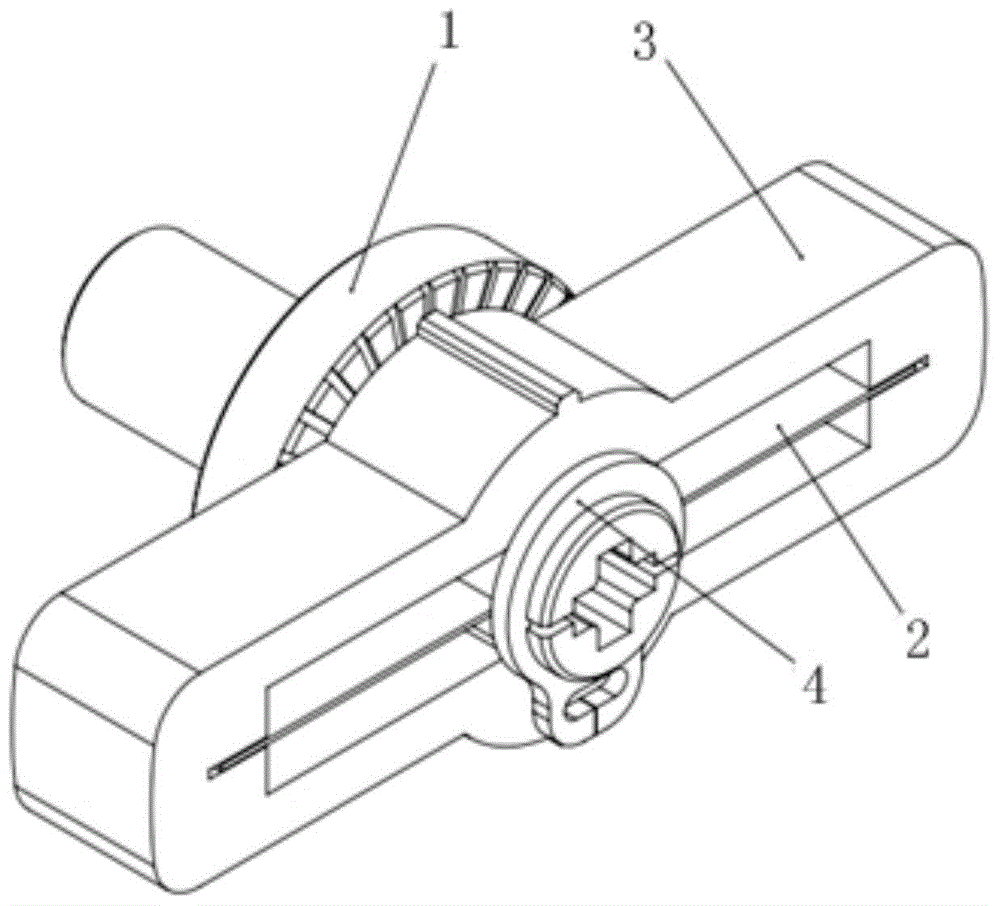

[0013] Such as figure 1 As shown, the torque-adjustable tensioning mechanism includes four parts: a tensioning joint 1 , a thin leaf spring 2 , a tensioning knob 3 and a C-shaped buckle 4 . The tensioning joint 1 is the connection between the torque-adjustable tensioning mechanism and the tensioned parts, and its internal shape can be customized according to the shape of the tensioned parts. The thin leaf spring 2 is made of spring steel and provides the elastic moment required for tensioning. The tensioning knob 3 provides a manually operated contact portion for convenient tensioning operation. The C-shaped buckle fixes the above four components to form a whole.

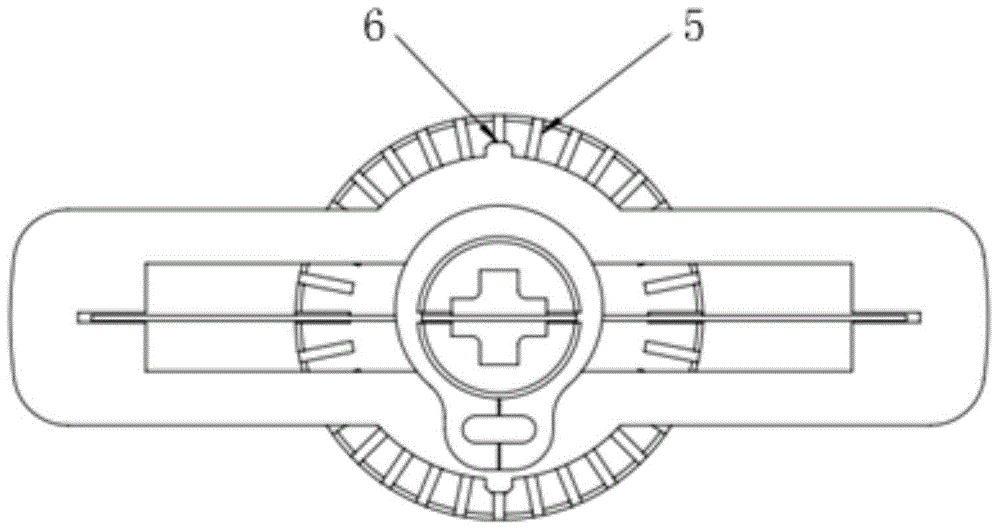

[0014] Such as figure 2 As shown, the tensioning joint 1 has a scale line 5 showing the magnitude of the tensioning moment, each scale line represents 0.05N·m, and the maximum torque range is determined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com