CAN bus integrated switch panel for truck

A CAN bus, integrated switch technology, applied in the field of CAN bus integrated switch panels, can solve the problems of less than 100,000 times of life, cumbersome switch wiring harness, large physical space, etc., to ensure timely delivery, highlight substantive features, and simplify wiring. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

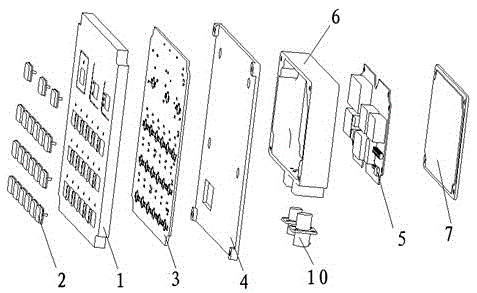

[0018] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

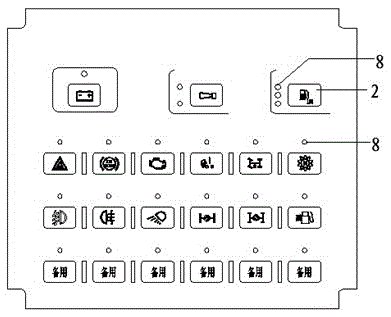

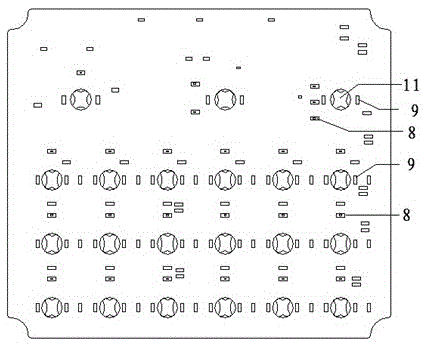

[0019] As can be seen from the accompanying drawings, a kind of truck CAN bus integrated switch panel of this program includes a central processing module 5, a key indicator light module 3 with a key body 2, an aviation plug interface 10, and the central processing module 5 Connect with key indicator light module 3, aviation socket 10 respectively, described central processor module 6 is arranged in central processing module shell 6, and the outer side of central processing module shell 6 is provided with metal bottom case 7, and central processing module The other side of the shell 6 is fixed on the key indicator light module shell 4, the key light indicator module 3 is arranged in the key light indicator module shell 4, and the key main body 2 is fixed on the front shell of the key ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com