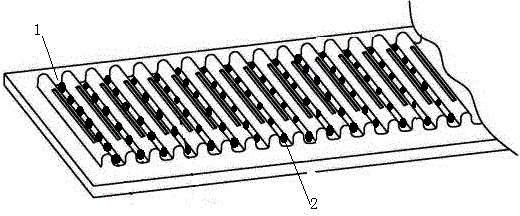

Board inserting frame of PCB inserting vehicle

A technology for PCB boards and plug-in racks, which is applied in the direction of trolleys, motor vehicles, single-axis trolleys, etc., and can solve problems such as damage, strong collision or scratching between PCB board and slot two or face combs, and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific embodiment:

[0011] A board rack for a PCB board board truck, characterized in that: a plurality of pulleys (2) are provided at the bottom of slot one (1) on the bottom surface of the triangular board board rack, A buffer pad (4) is provided in the slot two (3) on the surface, and the angled end formed by the bottom plate surface and the back plate surface of the triangular-shaped board frame is inclined downward. There are multiple pulleys in the slot one on the bottom surface, and the inside of the bottom surface is inclined downward, so that when placing the PCB board, the worker only needs to insert one end of the PCB board into the slot one lightly, and then the slot one can be used. The pulley inside slides into the board frame, and there is a buffer pad in the slot 2. After the PCB board slides into the board frame, it can provide a buffer force to prevent the PCB board from being...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com