Automatic carrying system for coloring process

A handling system and automatic technology, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of wasting manpower, heavy burden on workers, and reducing the efficiency of coloring process, so as to reduce labor intensity, improve production efficiency, and improve production operation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0032] Example

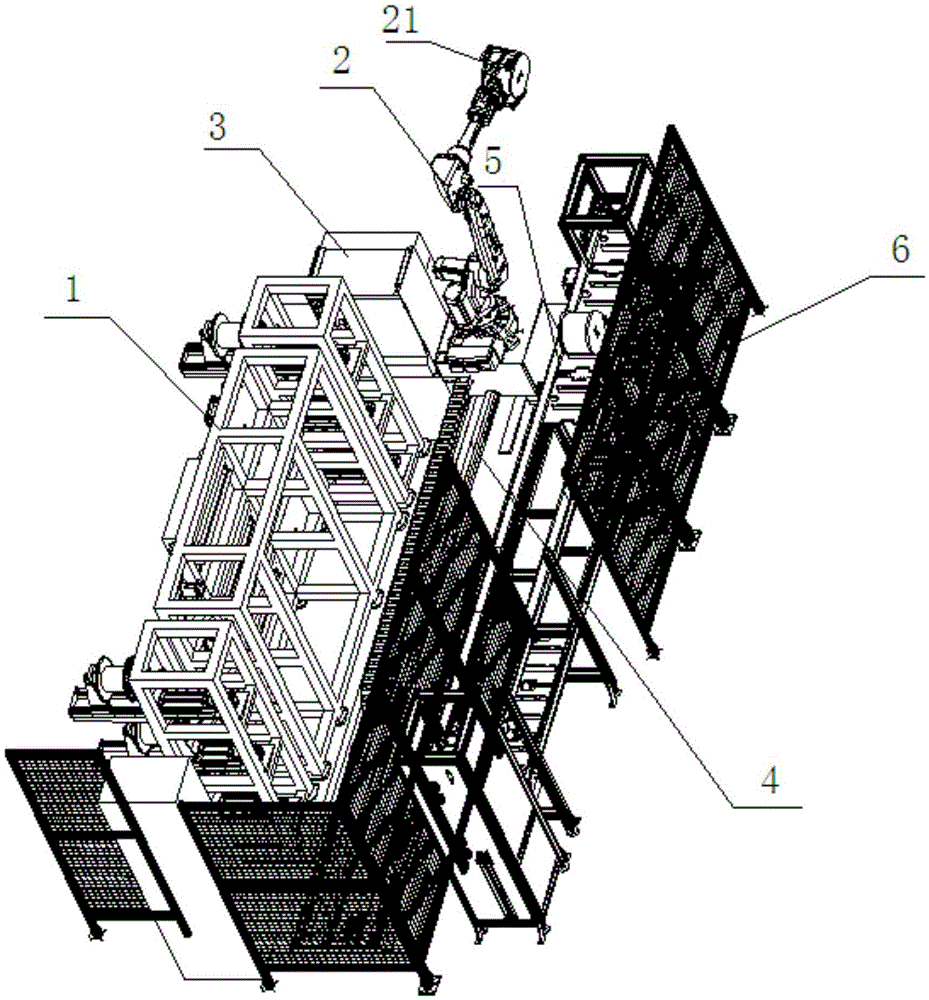

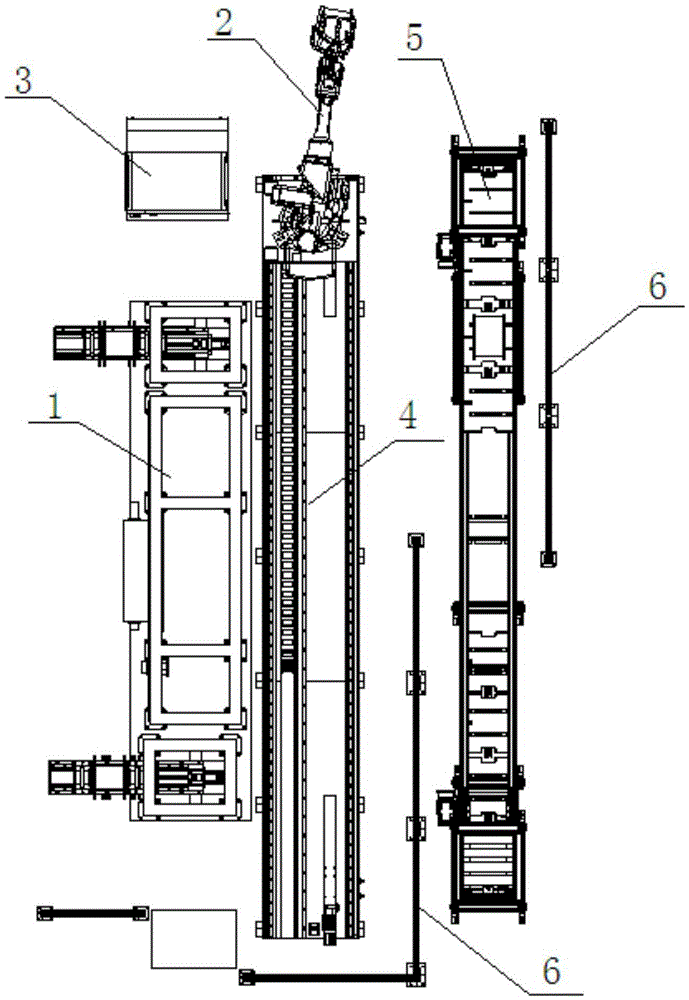

[0033] Such as Figure 1-2 As shown, this embodiment discloses an automatic handling system used in the coloring process, which includes a multi-head coloring machine 1, a robot that cooperates with the upper and lower plates of the above-mentioned multi-head coloring machine 1, 2, and a control cabinet 3 that controls the operation of the above-mentioned robot 2 , The guide rail system 4 for the automatic displacement of the robot 2, the conveyor line 5 of the conveyor reel, and the safety net 6 for protection. The safety net 6 is arranged on one side of the guide rail system 4, and is arranged at The outside of the above-mentioned conveying line 5. The guide rail system 4 is arranged between the multi-head coloring machine 1 and the conveying line 5 to facilitate the robot 2 to cooperate with the actions of the upper and lower spools in the coloring process of the multi-head coloring machine 1.

[0034] The working flow of the automatic handling system used in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com