Patents

Literature

30results about How to "Improve the efficiency of production operations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

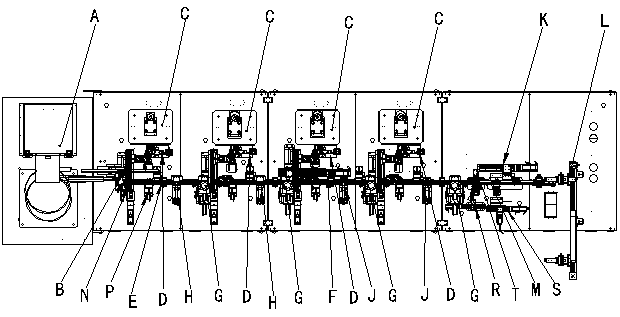

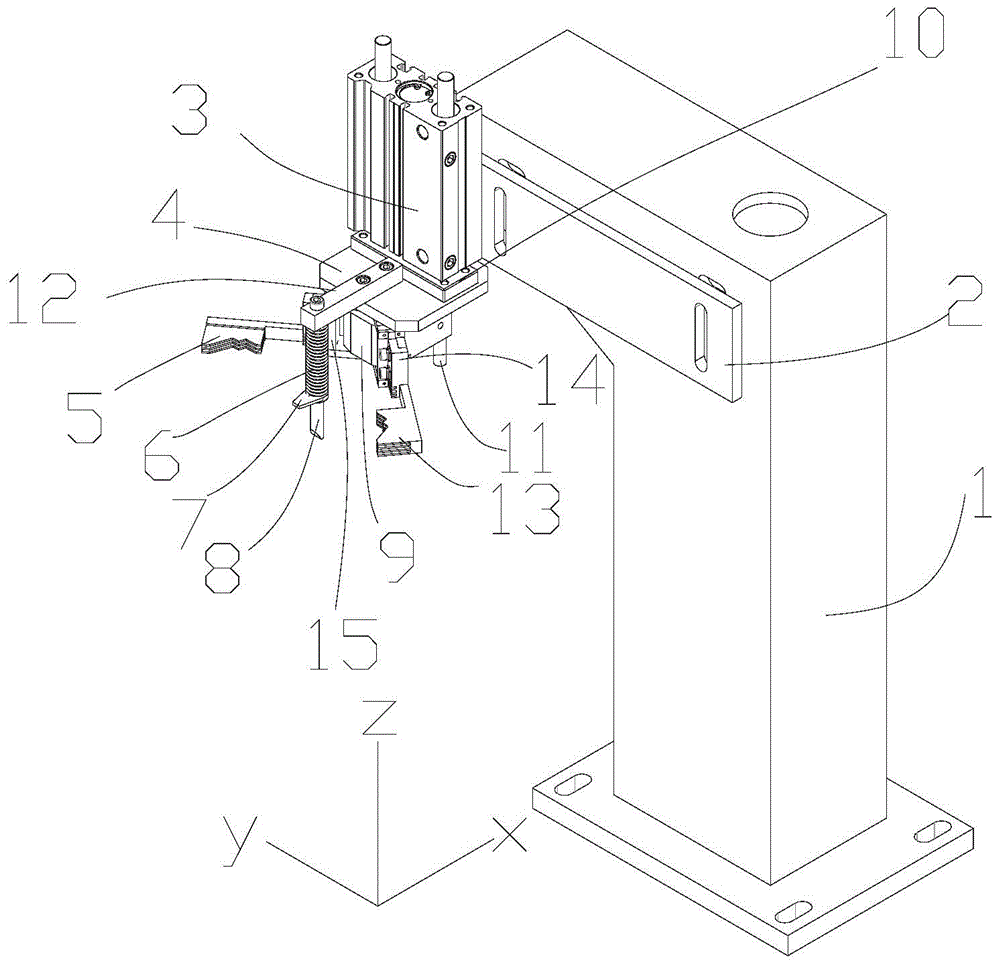

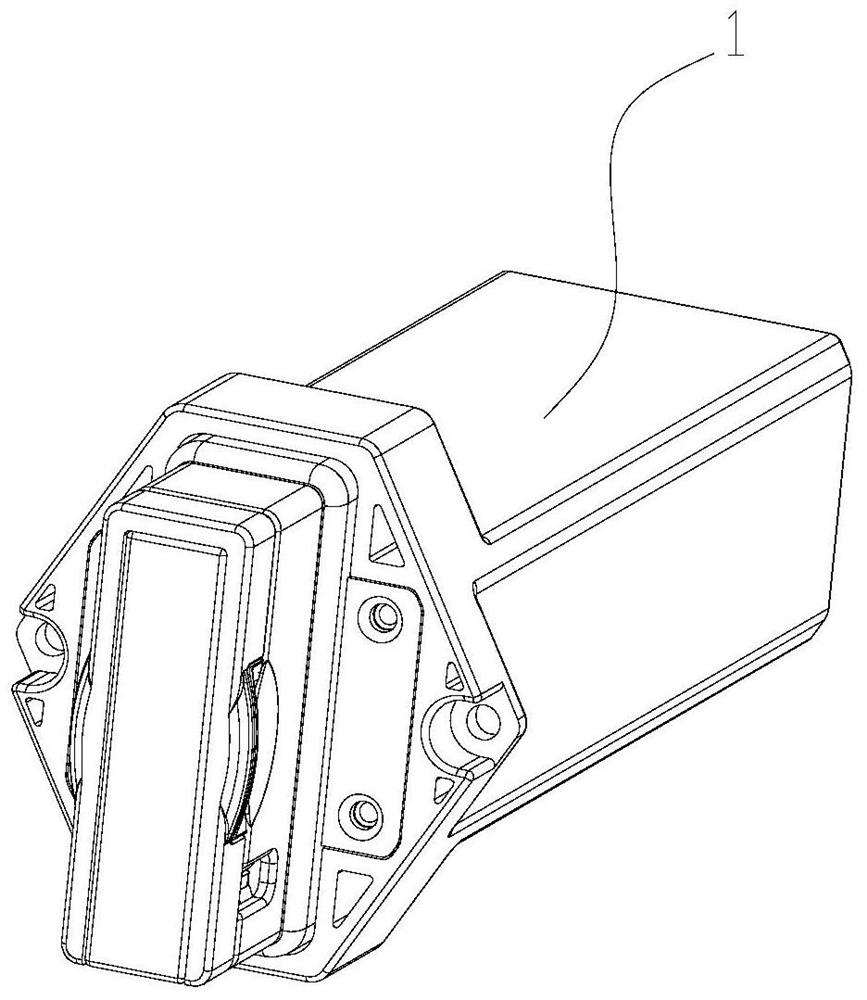

Pin inserting mechanism and pin inserting method for inserting four different mould pins into pin terminals

PendingCN108134303AImprove the efficiency of production operationsImprove product qualityContact member manufacturingContact member assembly/disassemblyEngineeringTransfer mechanism

The invention discloses a pin inserting mechanism and a pin inserting method for inserting four different mould pins into pin terminals. A first material shifting mechanism is connected with a material feeding mechanism. Each formed mould pin mould material forming mechanism is equipped with a connected material cutting-off mechanism, a material shifting pin assembly, a positioning mechanism, a transplanting mechanism, a second material shifting mechanism, a material pressing mechanism and a material cutting mechanism, wherein the material shifting pin assembly is arranged behind the first material shifting mechanism, the connected material cutting-off mechanism is arranged to the side of the formed mould pin mould material forming mechanism, and the positioning mechanism, the transplanting mechanism, the second material shifting mechanism, the material pressing mechanism and the material cutting mechanism are arranged on a main conveying line. After the completion of pin assembly, a high and low pin detection device, a visual detection device, a high and low pin detection and visual detection device, a material discharge and transfer mechanism and a material unloading mechanism are arranged. Each formed mould pin mould material forming mechanism is provided with a hydraulic pressurizing cylinder used for pressing and forming mould pins. The production efficiency is improved. Time and effort are saved. High assembly precision is achieved. The product quality is improved. The manufacture and labor costs are reduced.

Owner:HANGZHOU TAISHANG MACHINERY CO LTD

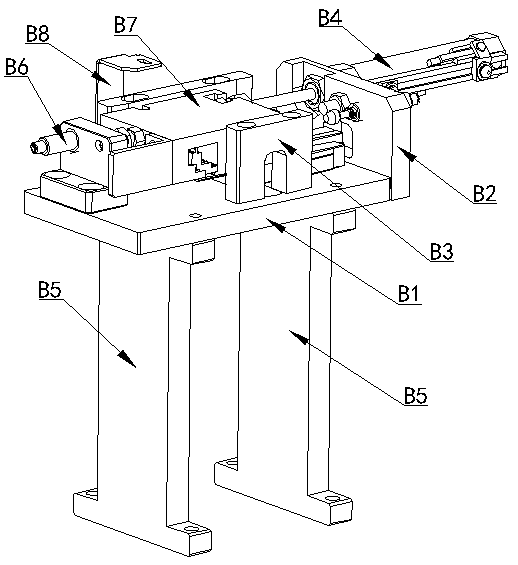

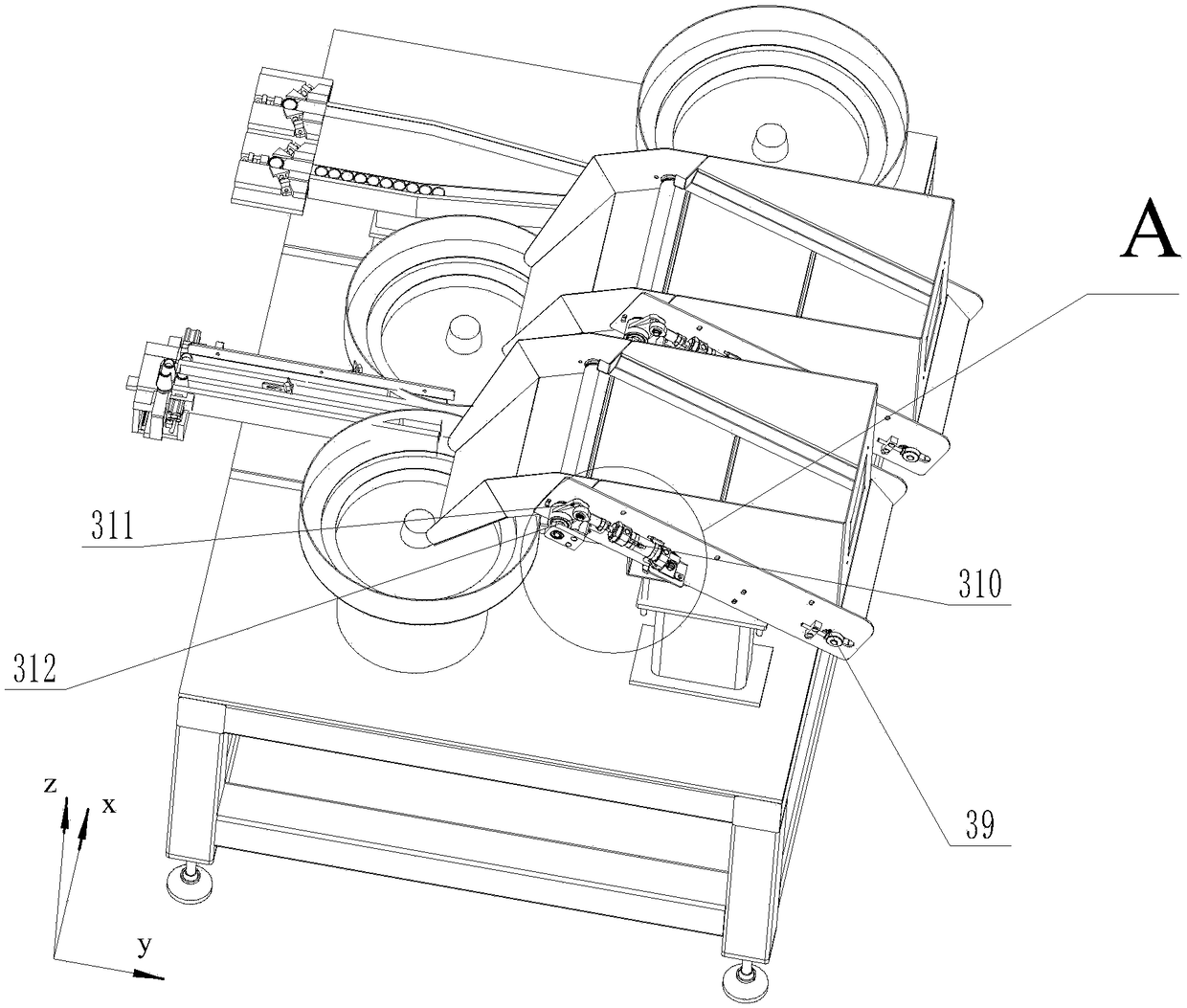

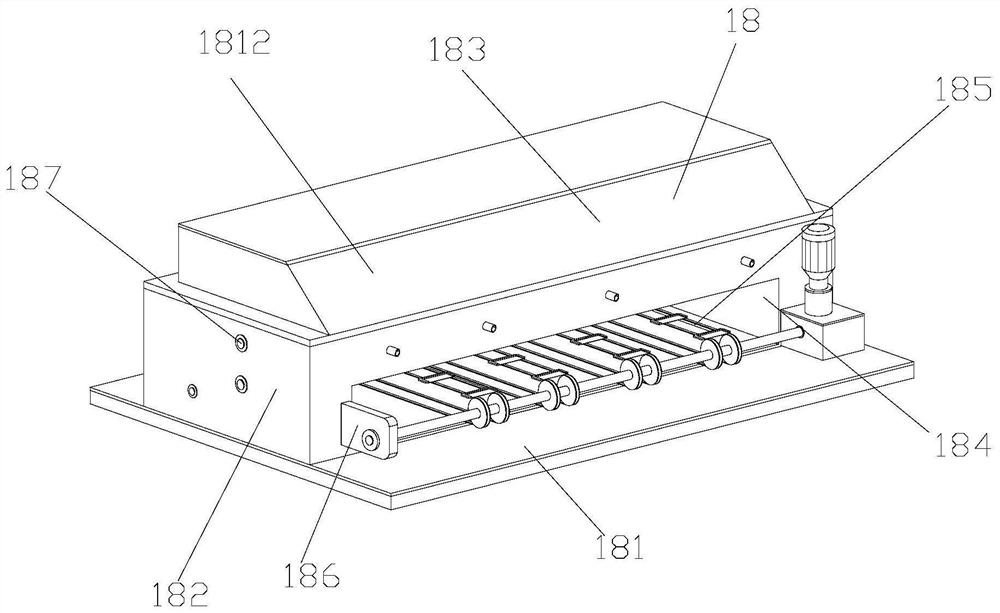

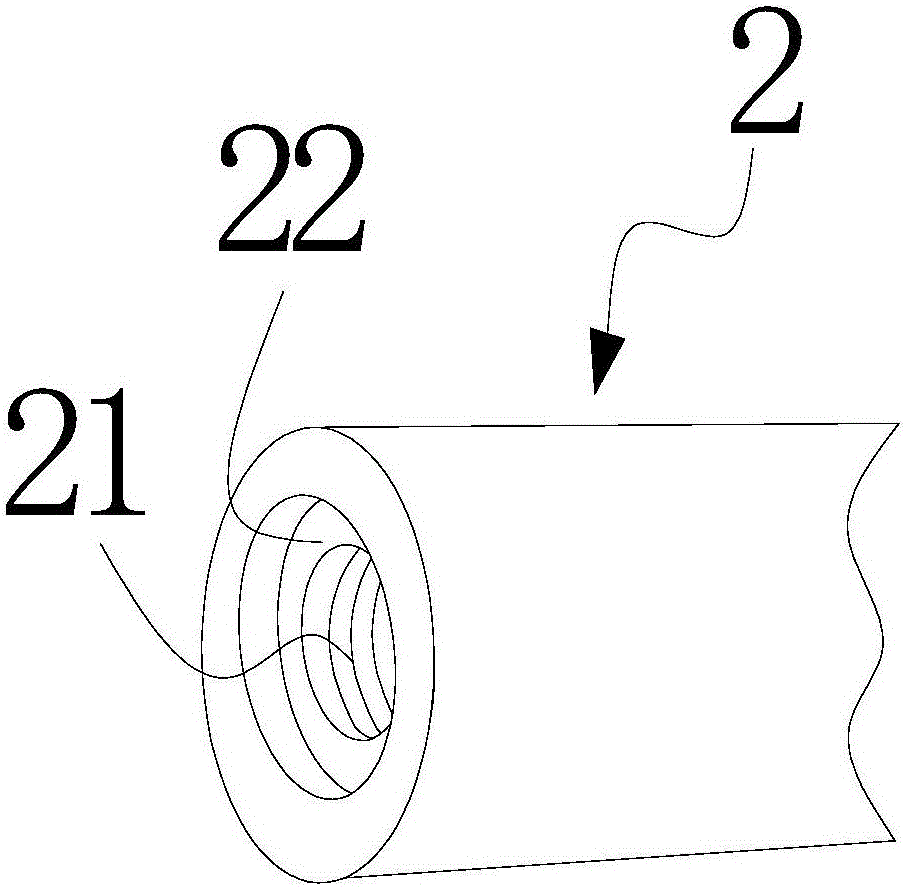

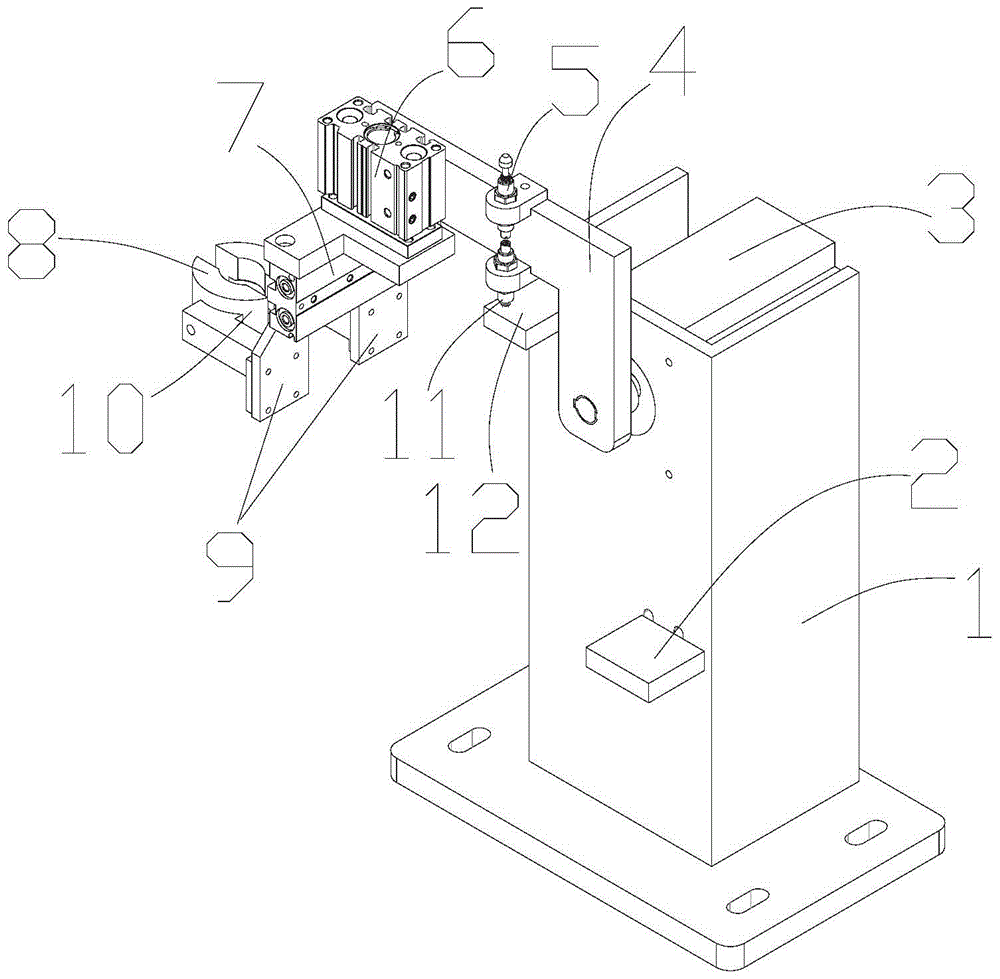

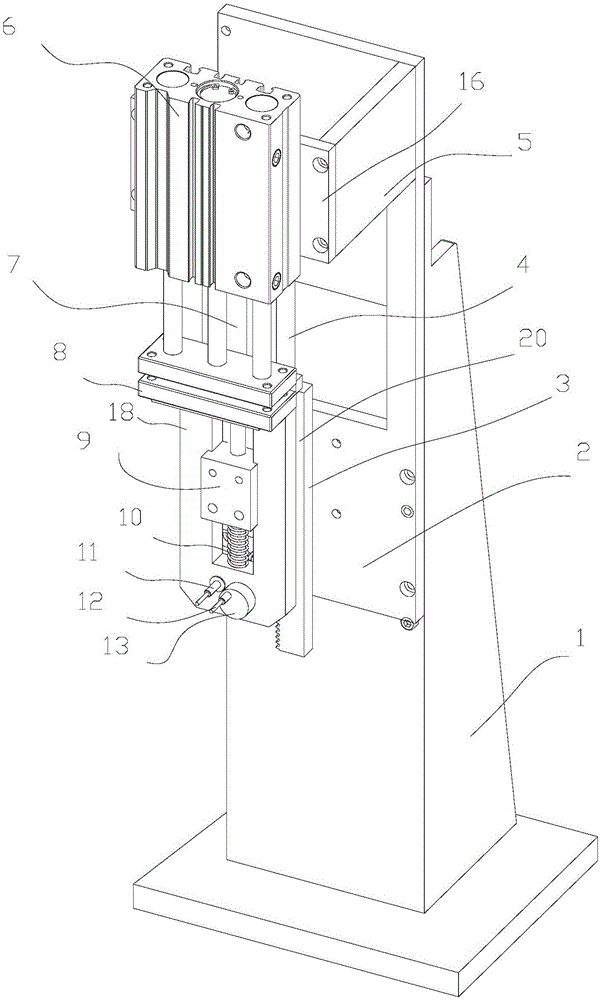

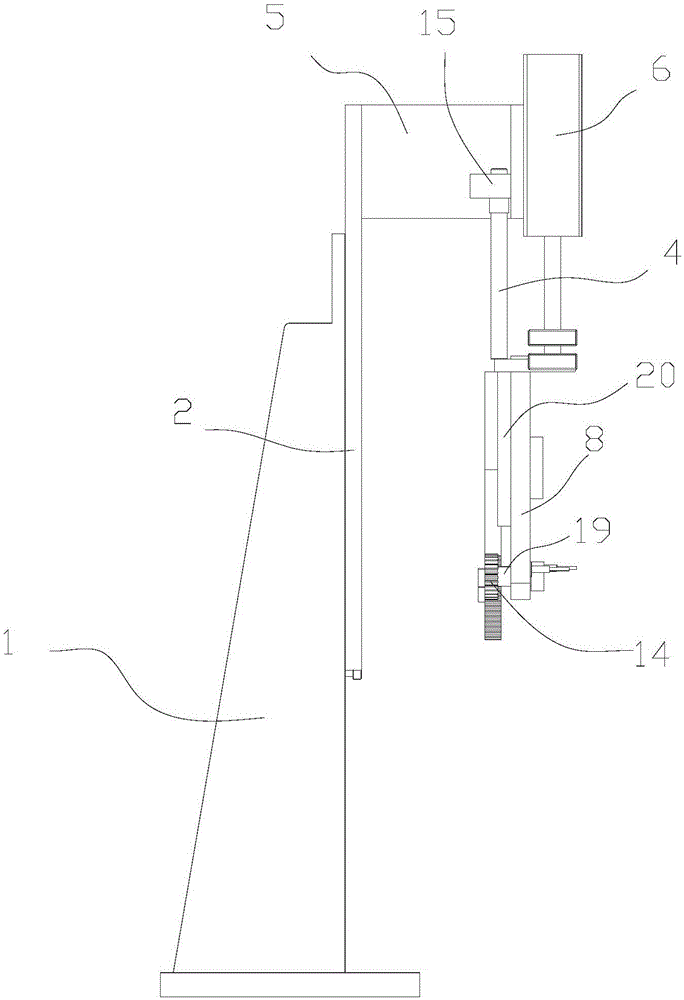

Translation carrying mechanism and operation method thereof

PendingCN109366120AIngenious structureIncrease profitAssembly machinesMetal working apparatusManipulatorAutomation

The invention provides a translation carrying mechanism. The translation carrying mechanism comprises a bottom mounting plate, the bottom mounting plate is provided with a translation sliding rail inthe X-axis direction, a translation sliding seat is arranged on the translation sliding rail, a translation air cylinder fixedly connected to the bottom mounting plate drives the translation sliding seat to slide along the translation sliding rail, a vertical sliding rail in the Y-axis direction is arranged on the translation sliding seat, a vertical sliding seat is arranged on the vertical sliding rail, a second air cylinder which is fixedly connected to the translation sliding seat drives the vertical sliding seat to slide along the vertical sliding rail, and the vertical sliding seat is fixedly connected with a translation carrying manipulator for clamping a workpiece. According to the translation carrying mechanism and an operation method thereof, the automation degree is high, the translation carrying accuracy is high, and the production efficiency is high.

Owner:湖北火爆机器人科技有限公司

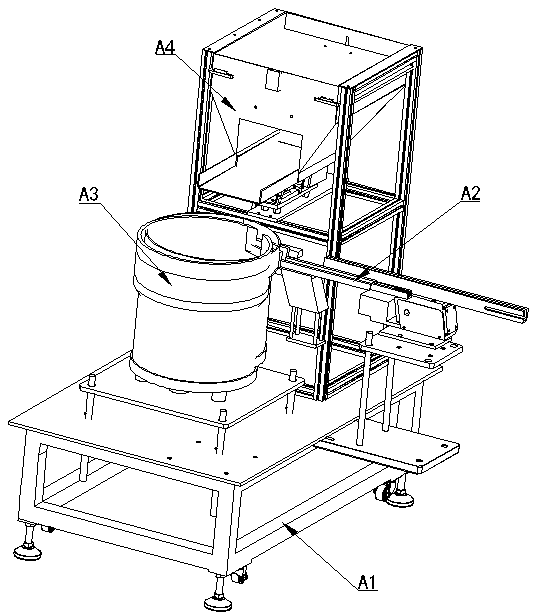

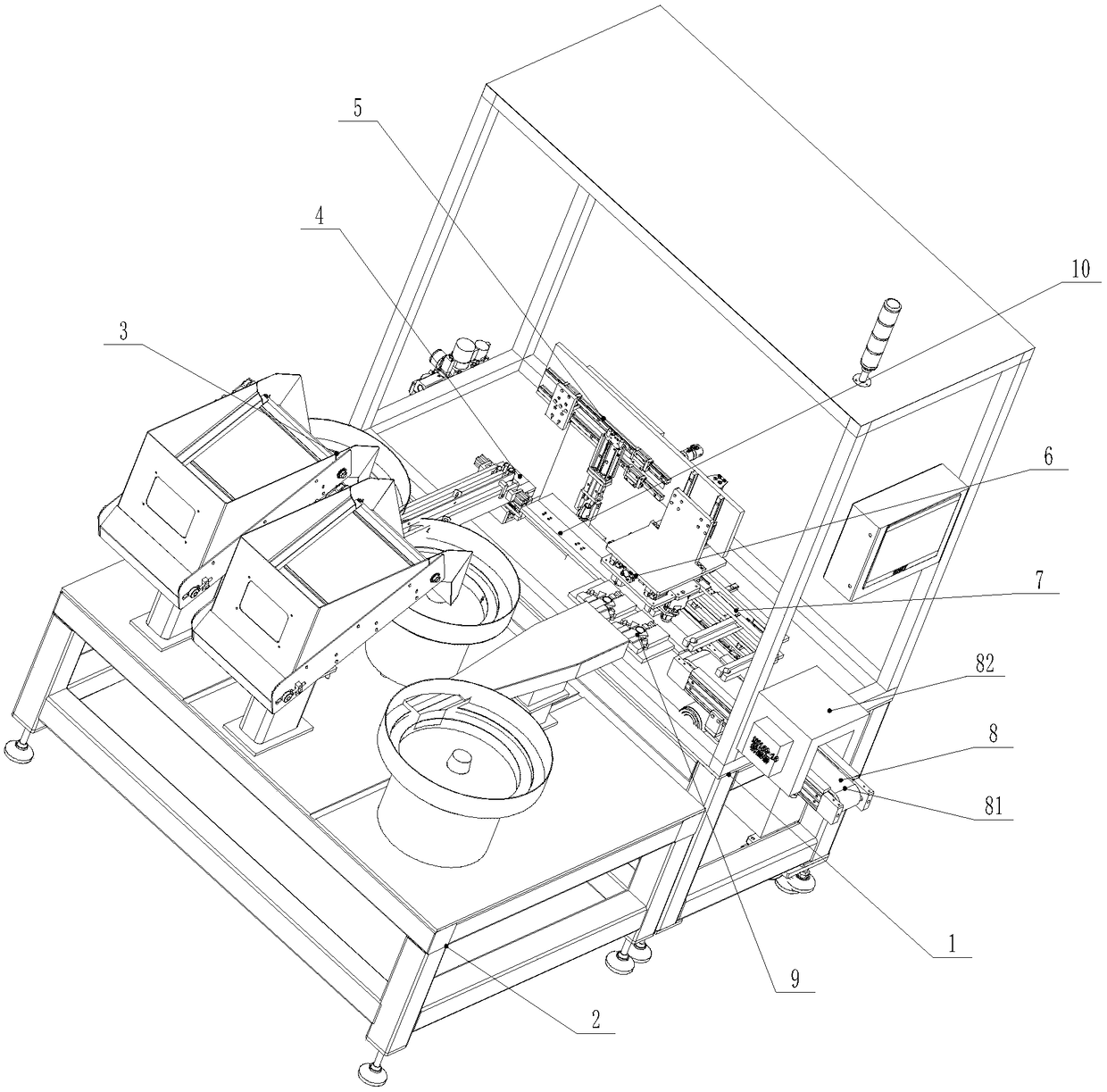

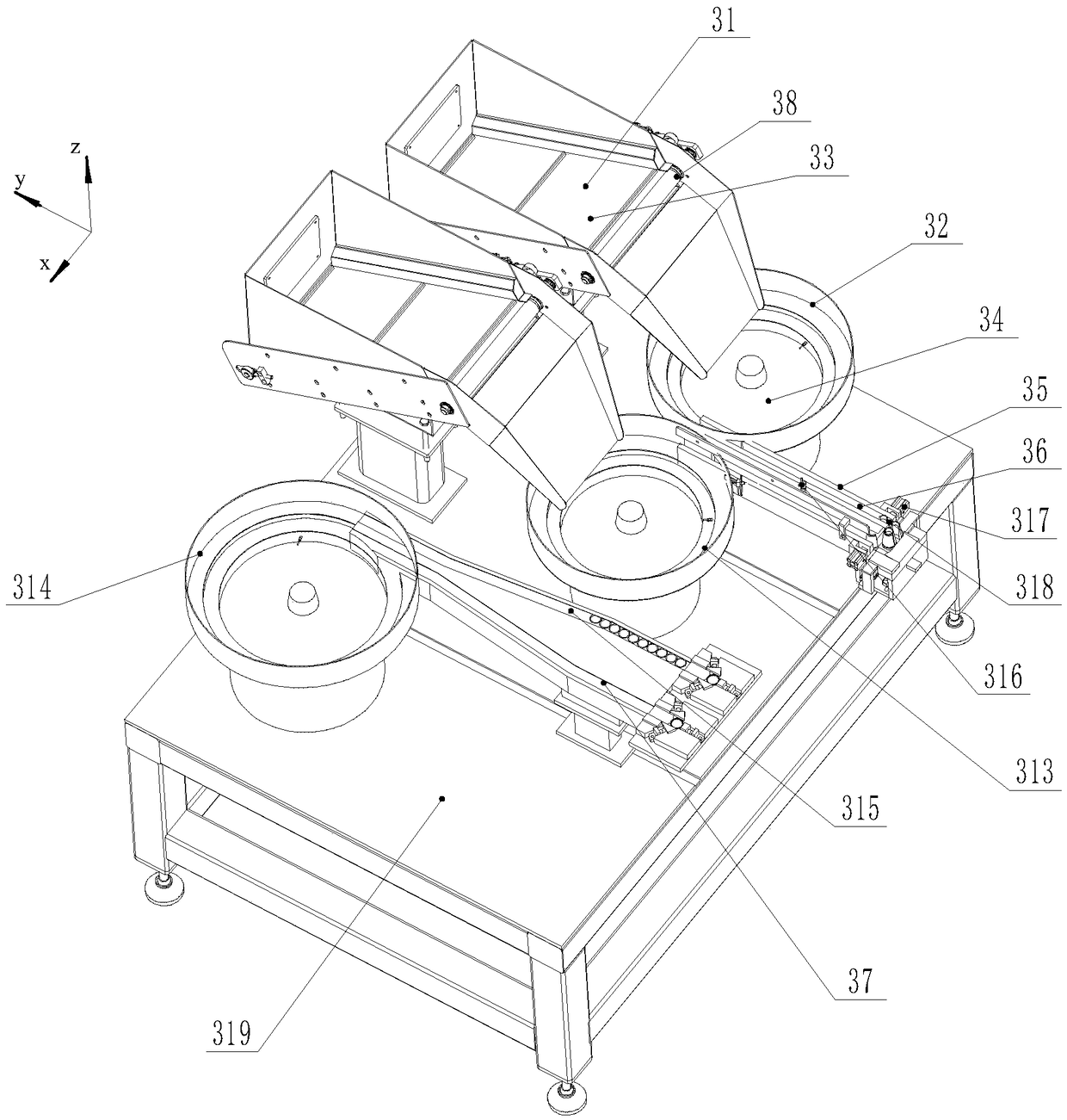

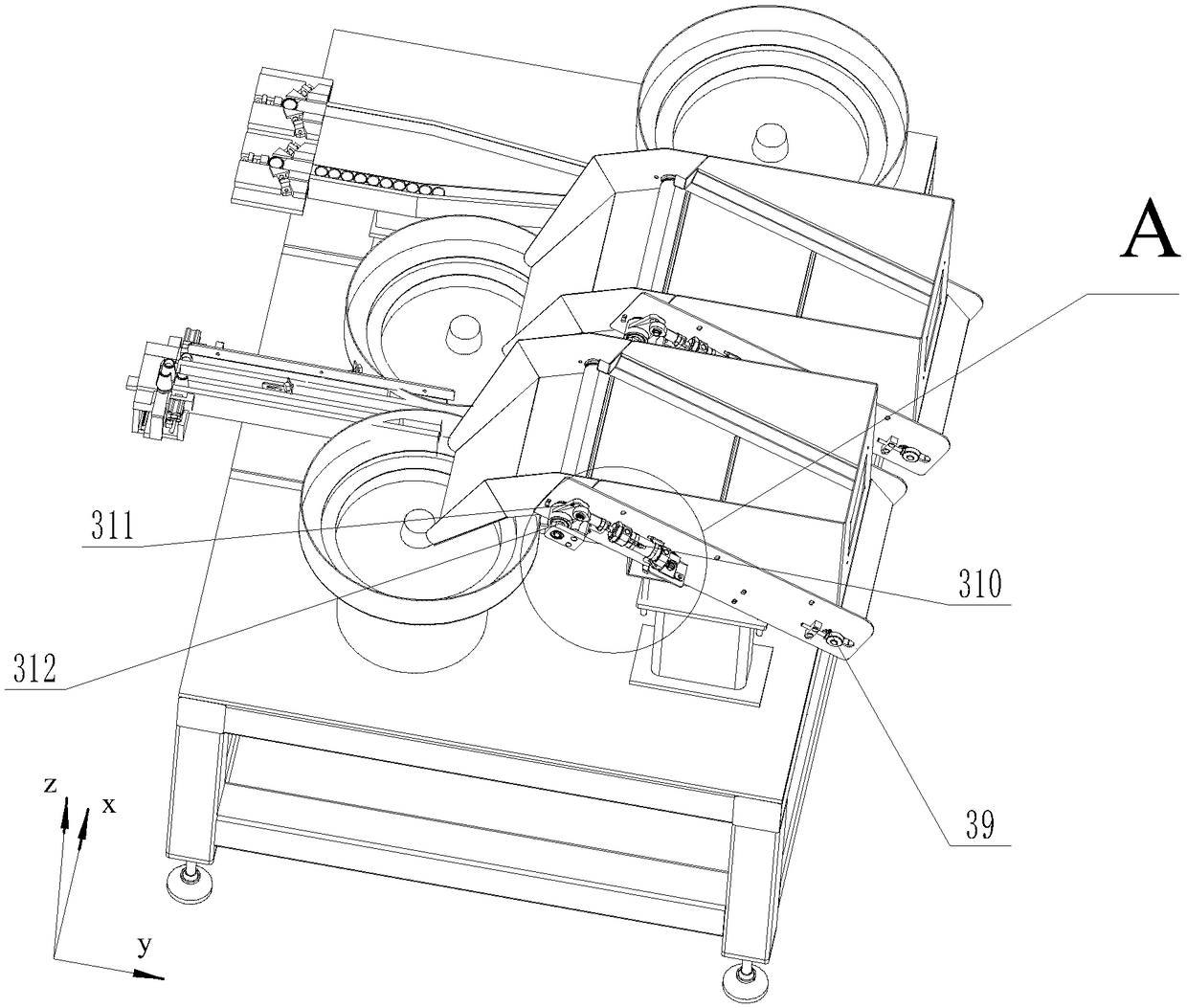

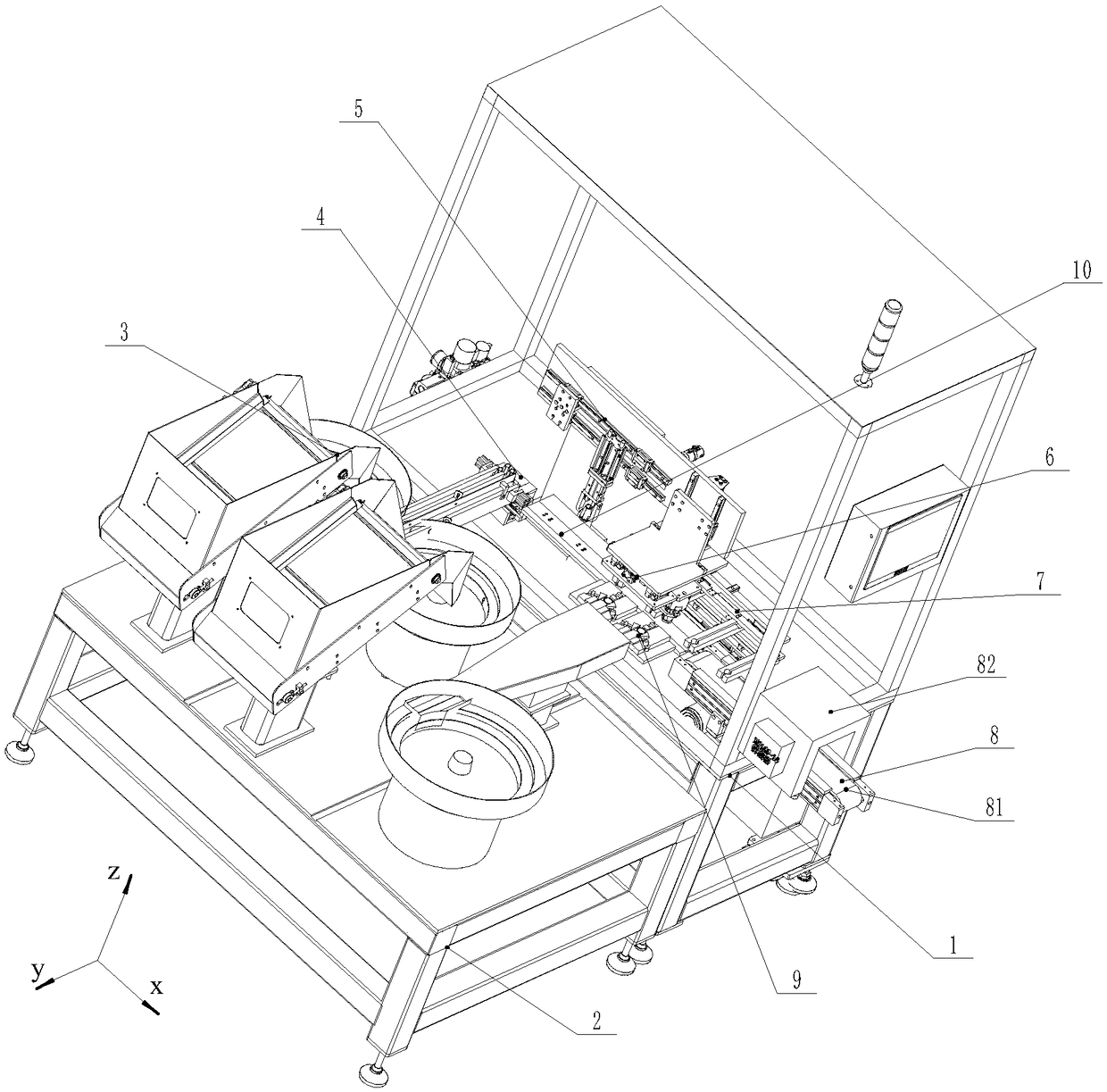

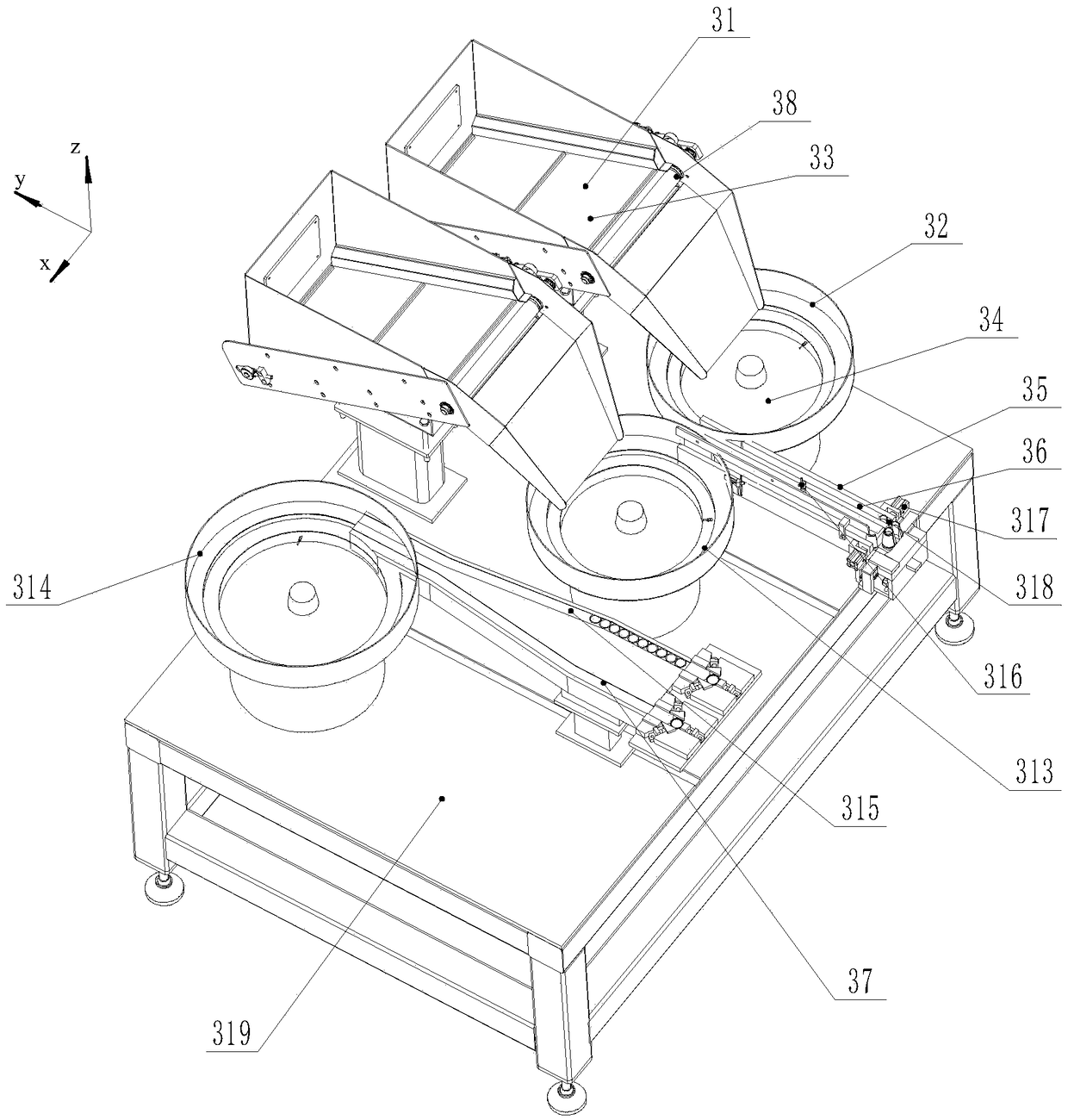

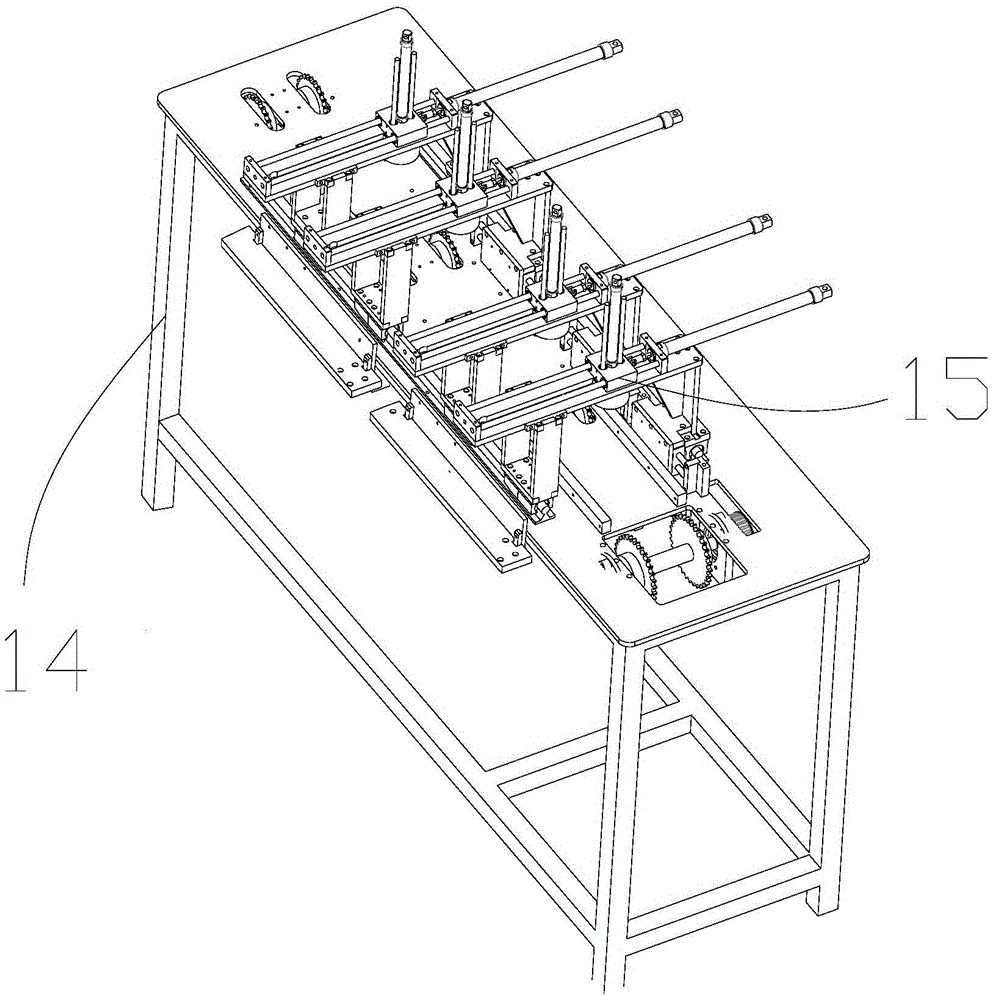

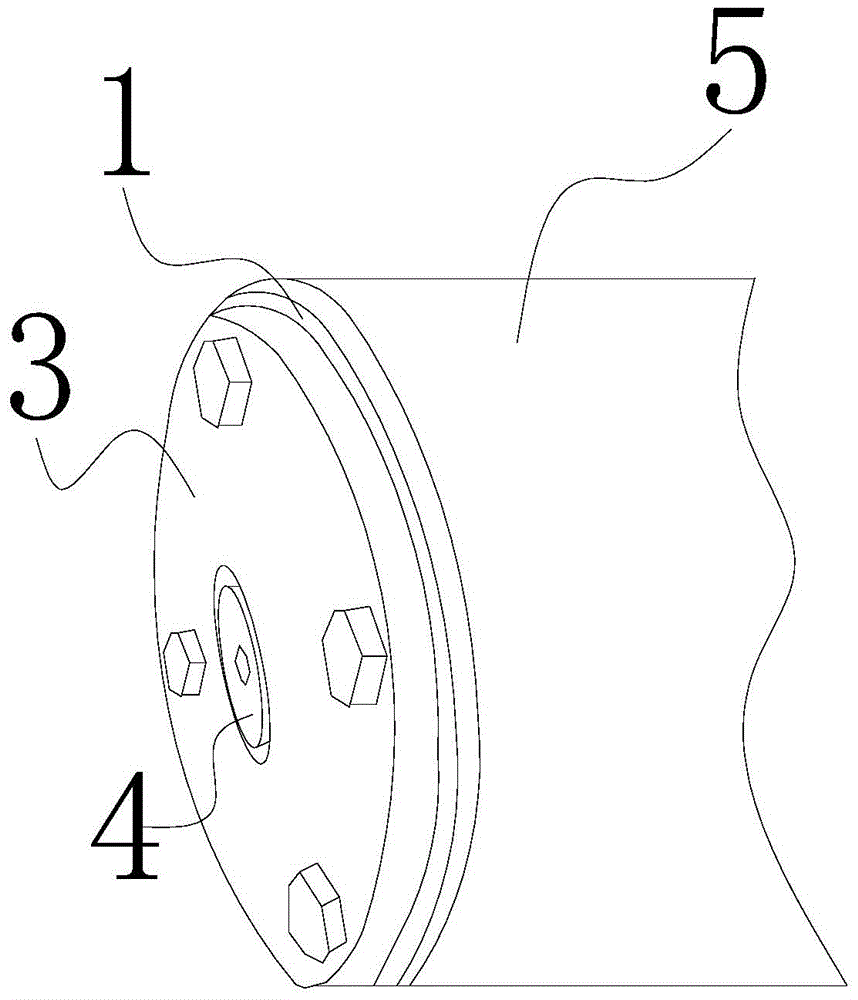

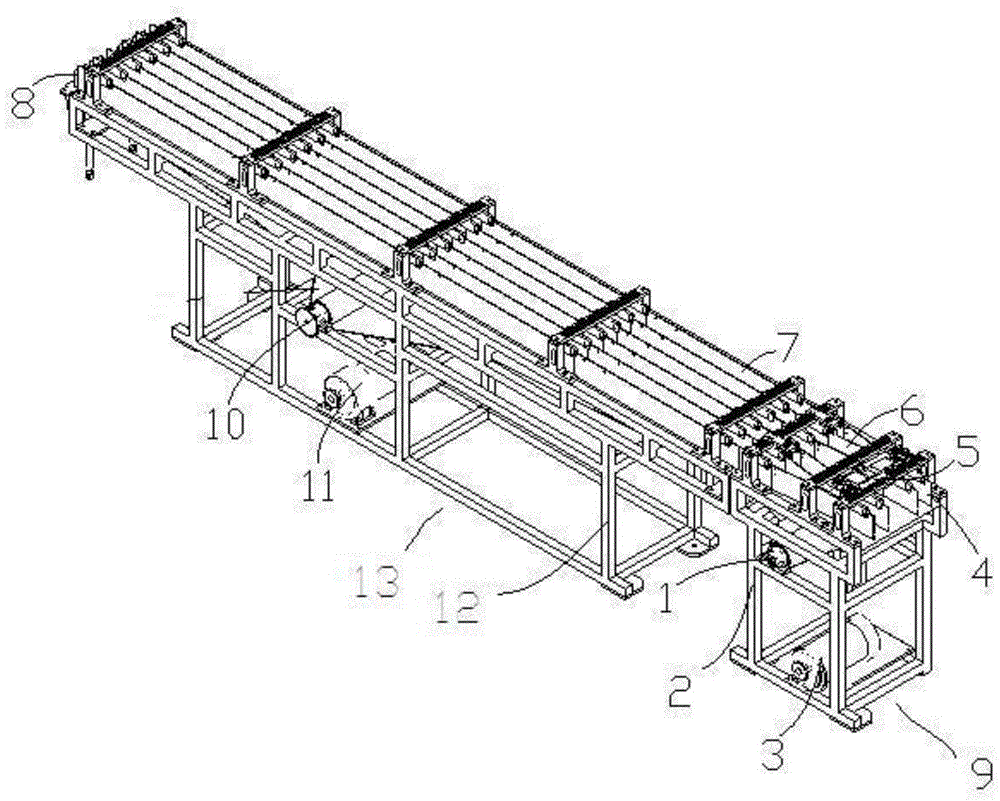

Automated assembly equipment of O-shaped ring of anchorage device and operation method thereof

PendingCN109352296AThe structure is compactSmall footprintMetal working apparatusEngineeringLeather belt

According to the equipment, half anchorage devices and O-shaped rings can be supplied to an anchorage device combining mechanism and an O-shaped ring loading platform in order from a vibration disc feeding device, the anchorage devices are carried by a clamping and carrying mechanism, and then are horizontally moved and conveyed to a sleeving position through a translation carrying mechanism, theO-shaped rings are precisely arranged on annular grooves of the anchorage devices in a sleeved mode through an O-shaped ring sleeving mechanism, then the anchorage devices are horizontally moved and conveyed to a belt of a belt discharging mechanism by the translation carrying mechanism, and discharging is carried out after demagnetization through a demagnetization box. The automated assembly equipment of the O-shaped ring of the anchorage device is high in whole process automation degree, high in accuracy of the sleeving of the O-shaped rings, and high in production efficiency from the half anchorage devices and the O-shaped rings feeding and assembling to complete discharging.

Owner:湖北火爆机器人科技有限公司

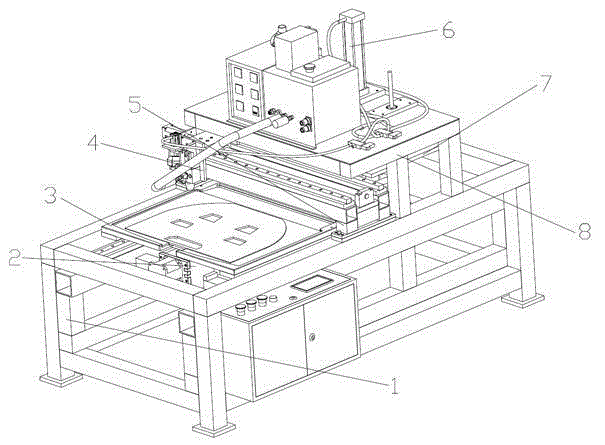

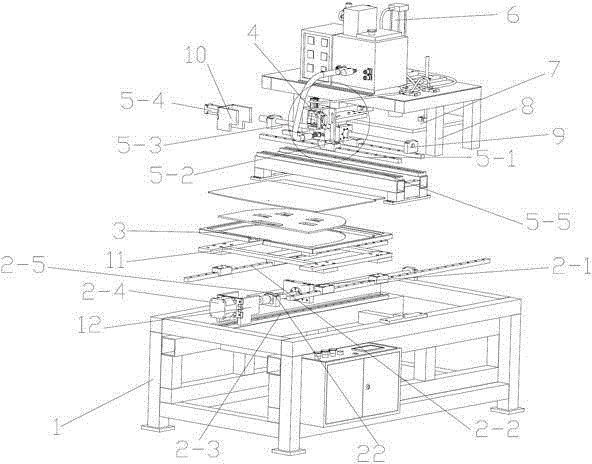

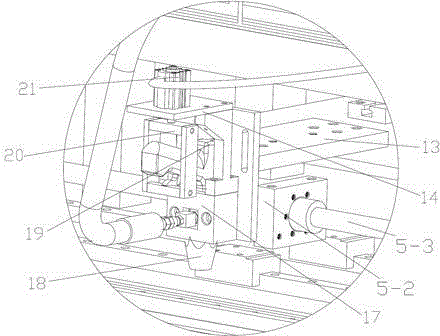

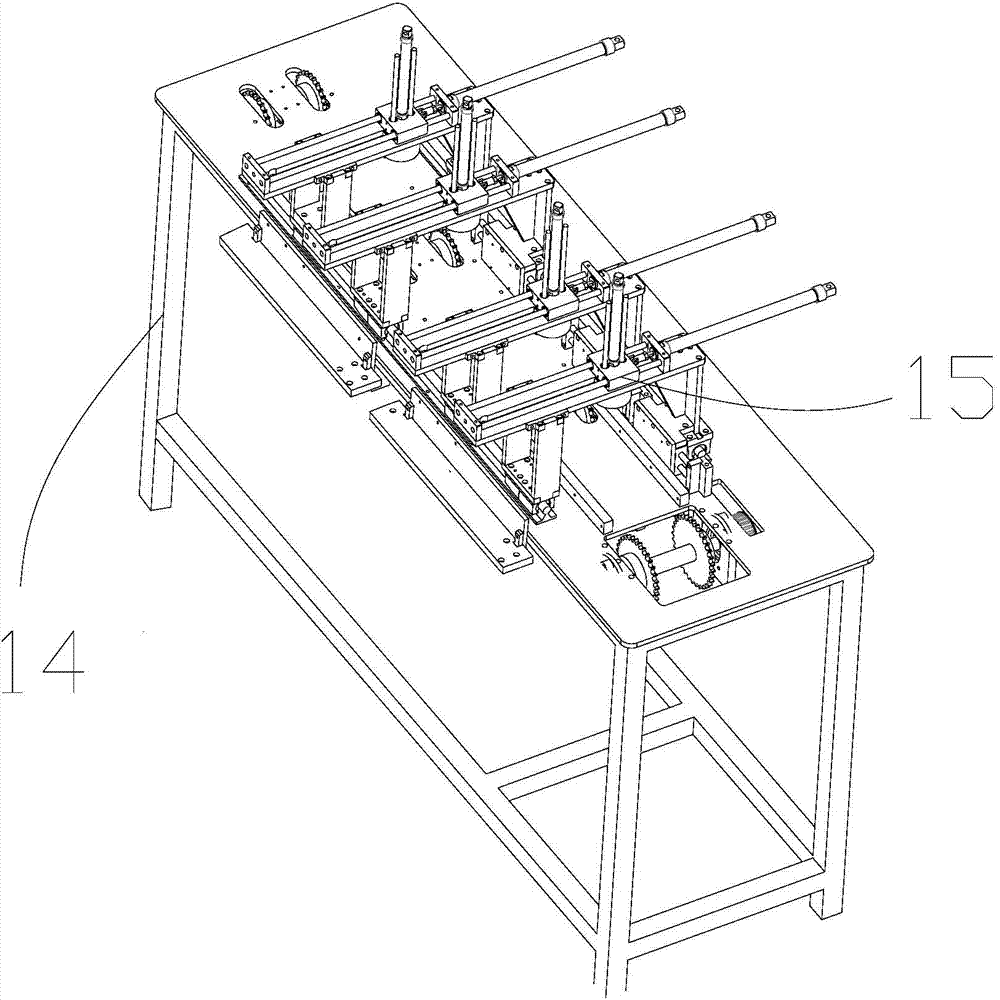

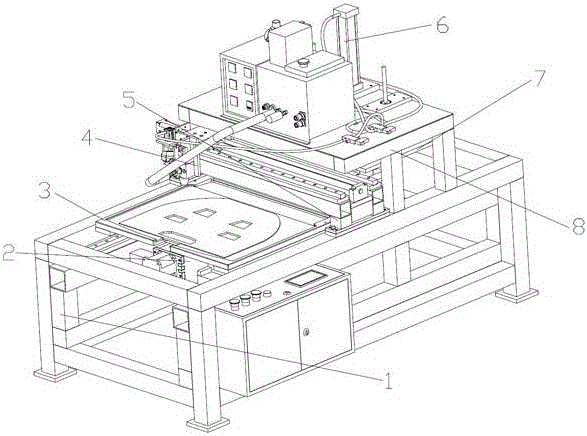

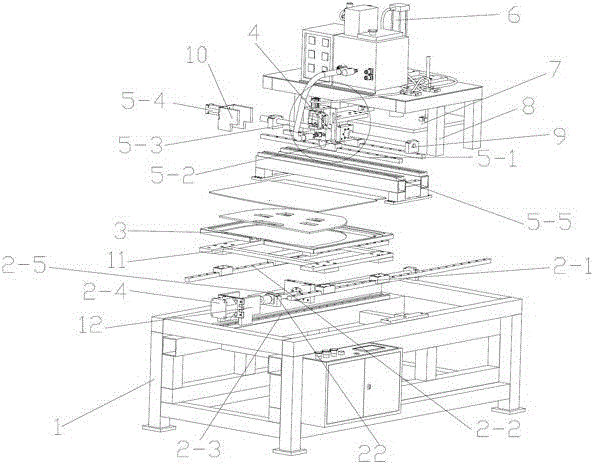

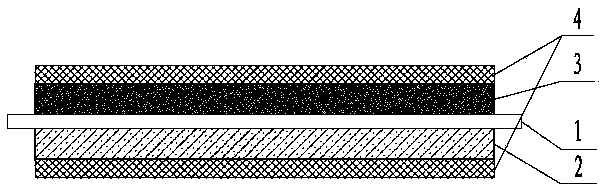

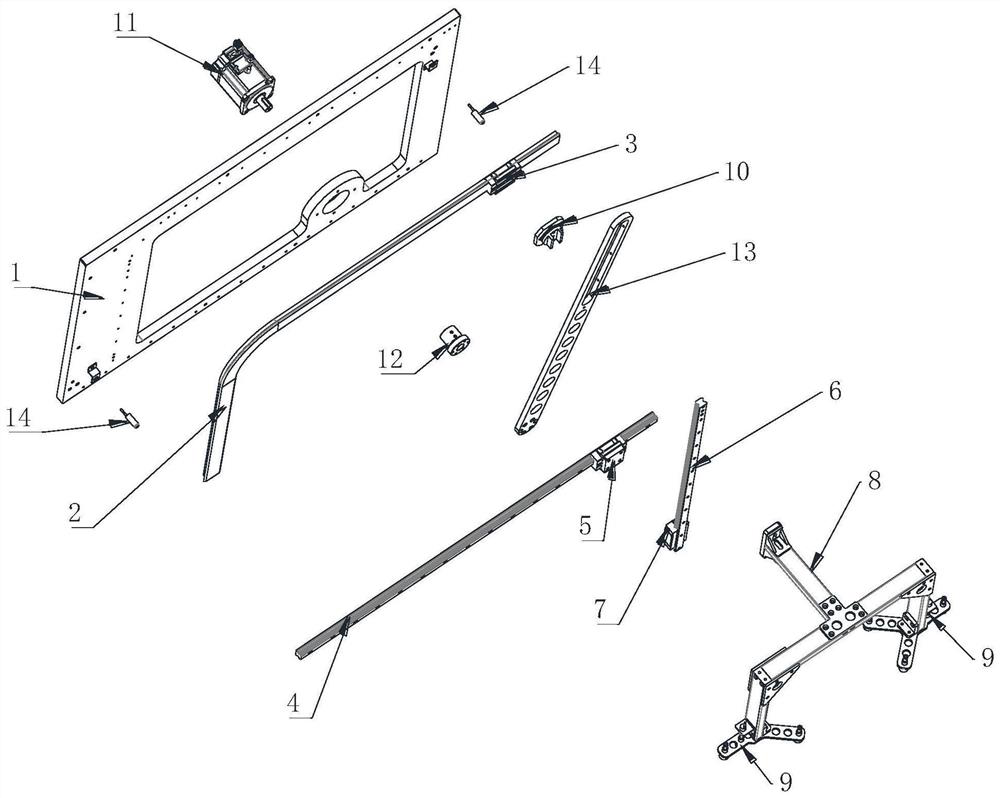

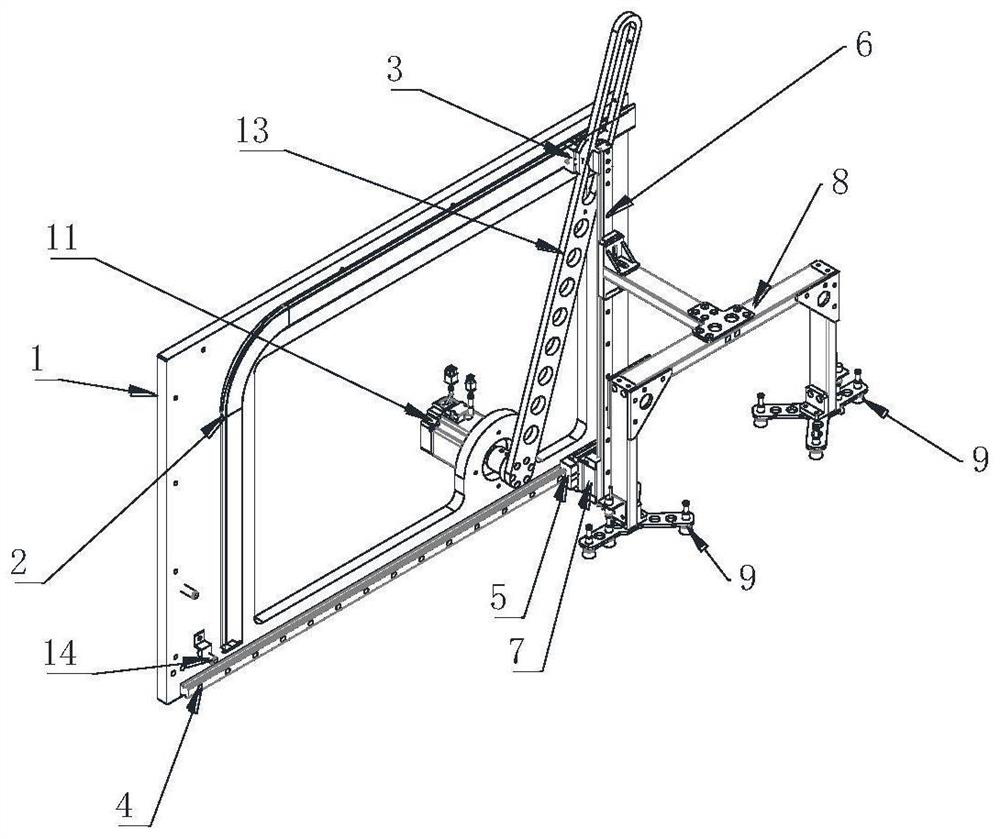

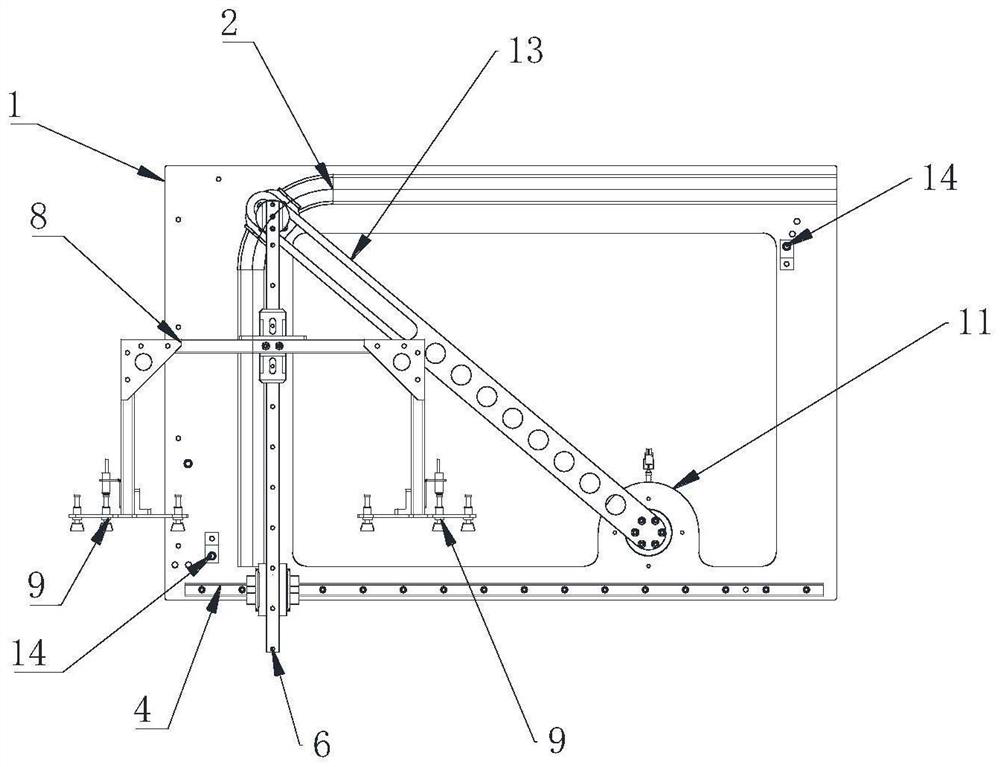

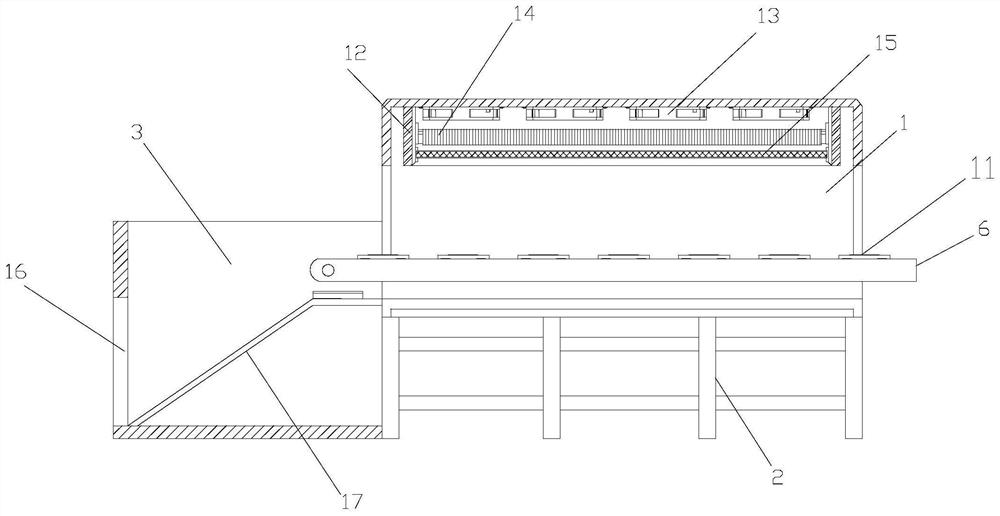

Automatic glue spraying and compounding all-in-one machine and manufacturing method for automobile trunk carpet production

ActiveCN104527203AConform to designFit for useLaminationLamination apparatusEngineeringVertical displacement

The invention discloses an automatic glue spraying and compounding all-in-one machine and a manufacturing method for automobile trunk carpet production. A template of the automatic glue spraying and compounding all-in-one machine is moved by a horizontal sliding mechanism so that the purpose of horizontal displacement glue spraying of a polypropylene cellular board on the template can be achieved through a glue spraying device. The glue spraying device is moved by a vertical sliding mechanism so that the purpose of vertical displacement glue spraying of the polypropylene cellular board on the template can be achieved through the glue spraying device. Meanwhile, the glue sprayed polypropylene cellular board on the template is glued to a sound insulation felt. The glued sound insulation felt and the polypropylene cellular board on the template are quickly transferred to the position below a pressing plate by the horizontal sliding mechanism. The pressing plate is automatically activated and quickly pushed by a power unit so that further pressing, compounding and molding can be carried out on the glued sound insulation felt and the polypropylene cellular board. According to the automatic glue spraying and compounding all-in-one machine and the manufacturing method for the automobile trunk carpet production, the compounding fastness and the production efficiency of an automobile trunk carpet are improved, and the compounded and molded automobile trunk carpet is good in operation performance.

Owner:NINGBO SUNLIGHT MOTOR PARTS

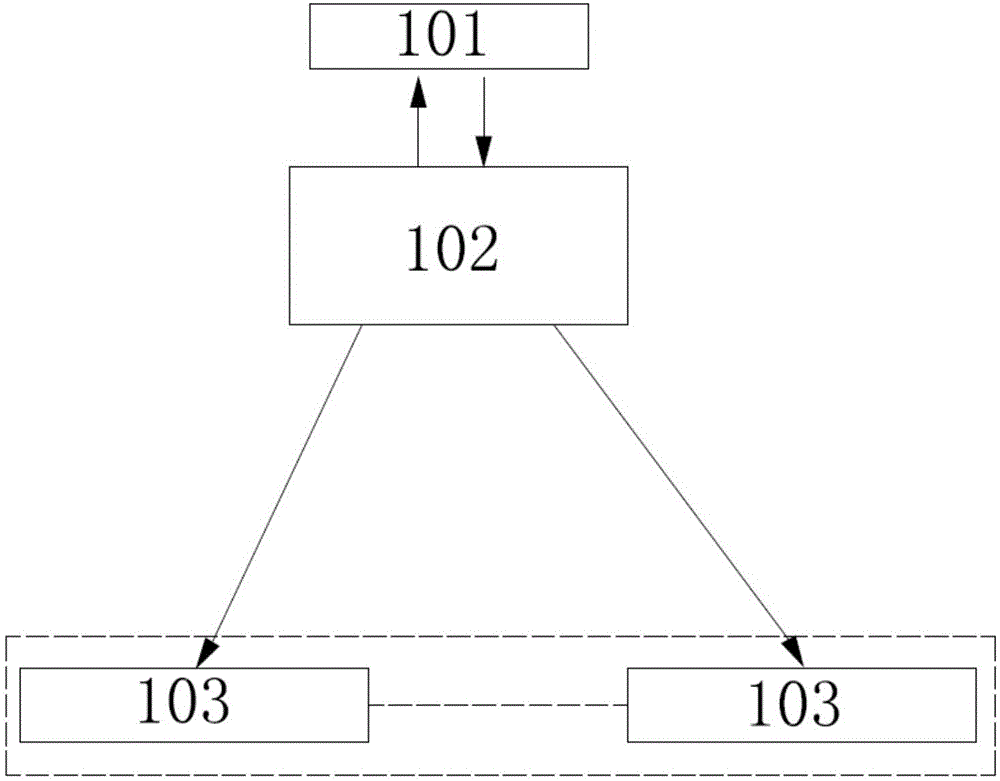

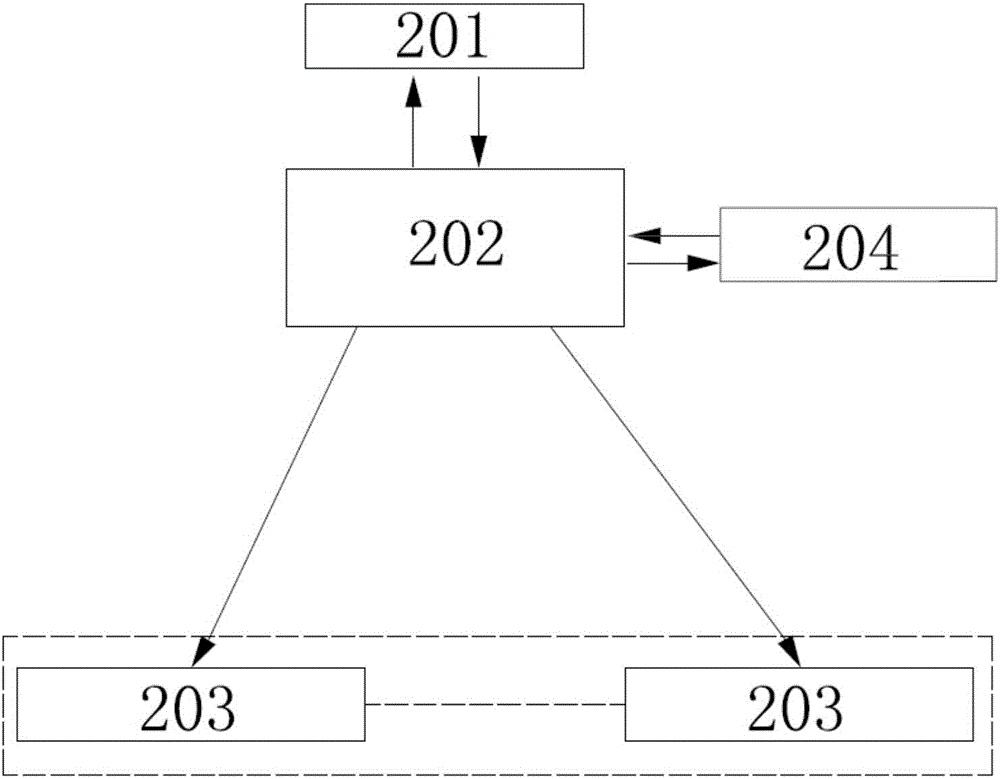

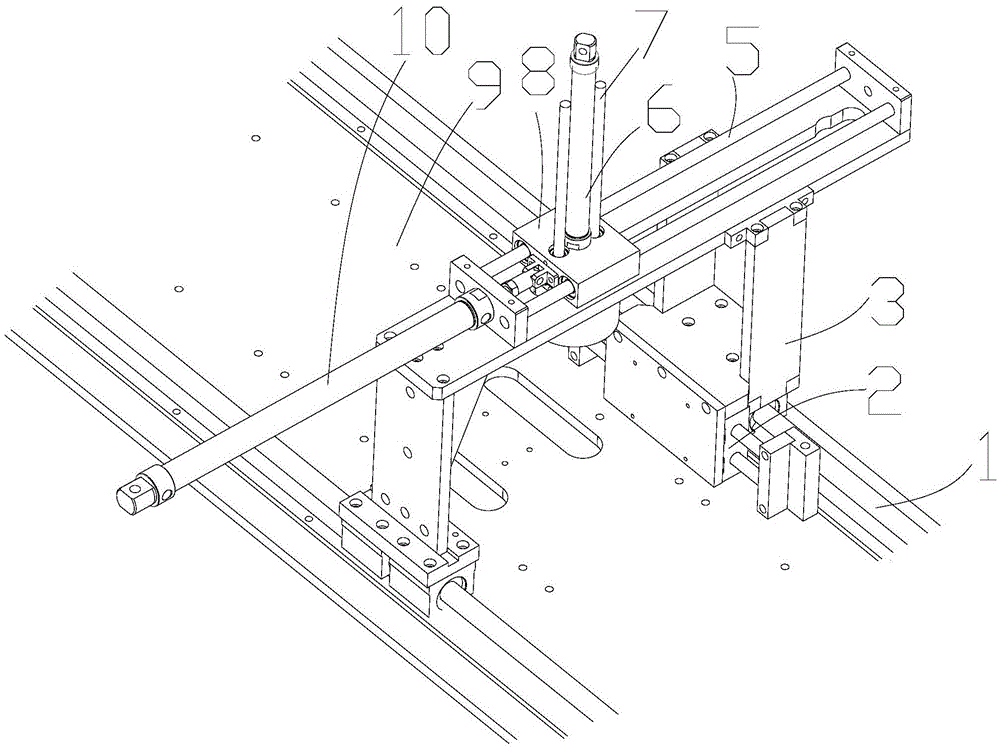

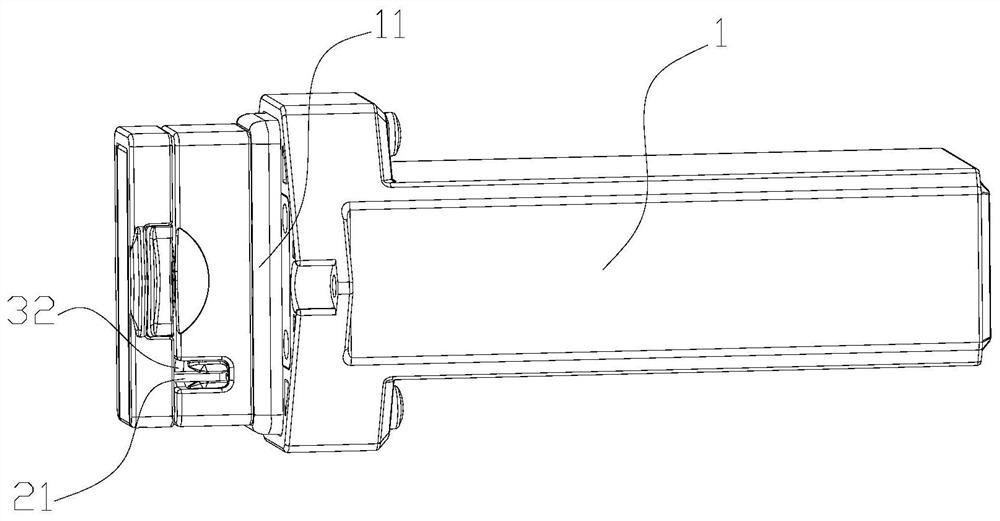

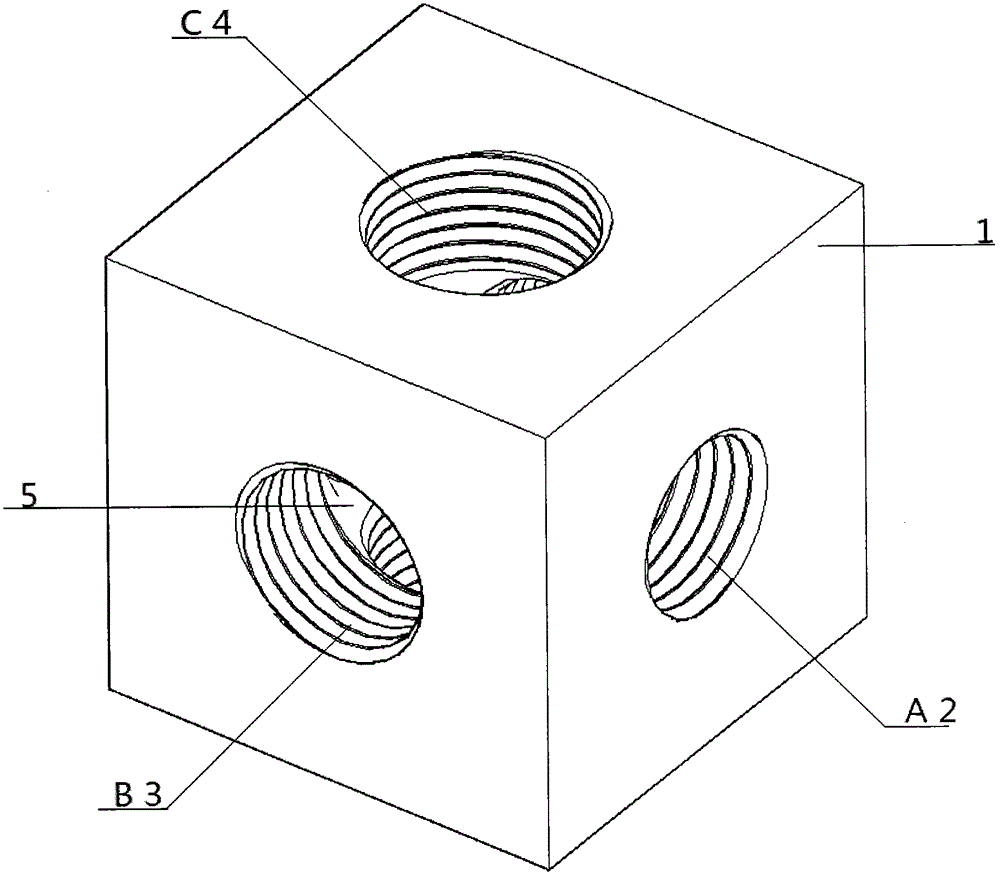

Distribution device and distribution system

InactiveCN103754638ASimple structureVersatileConveyor partsDistribution systemIndustrial engineering

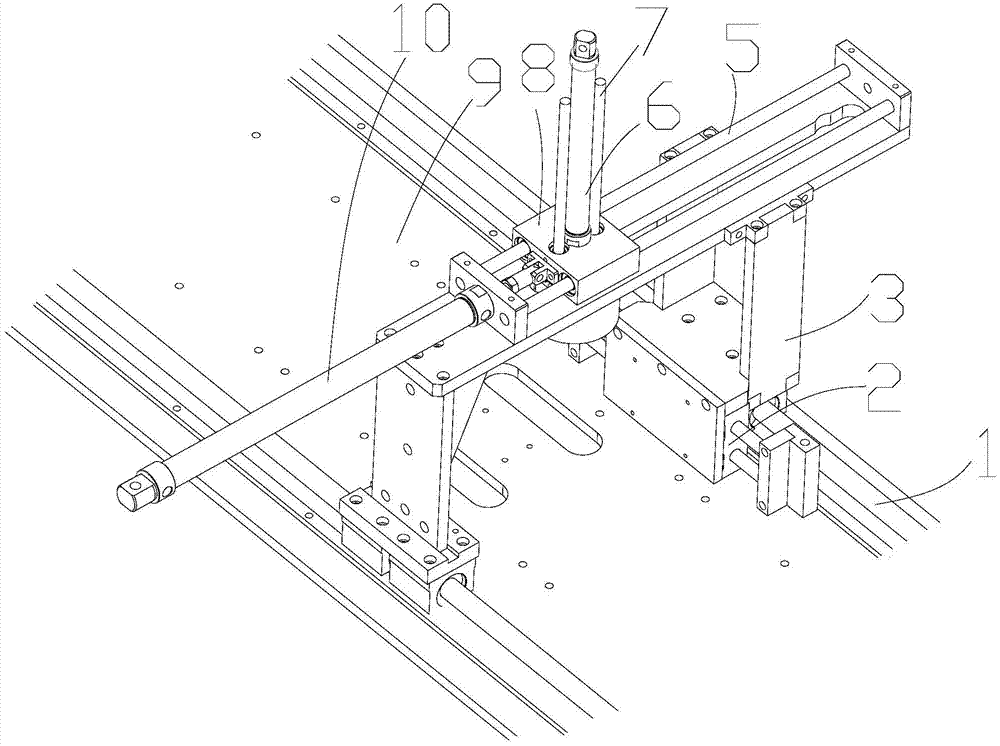

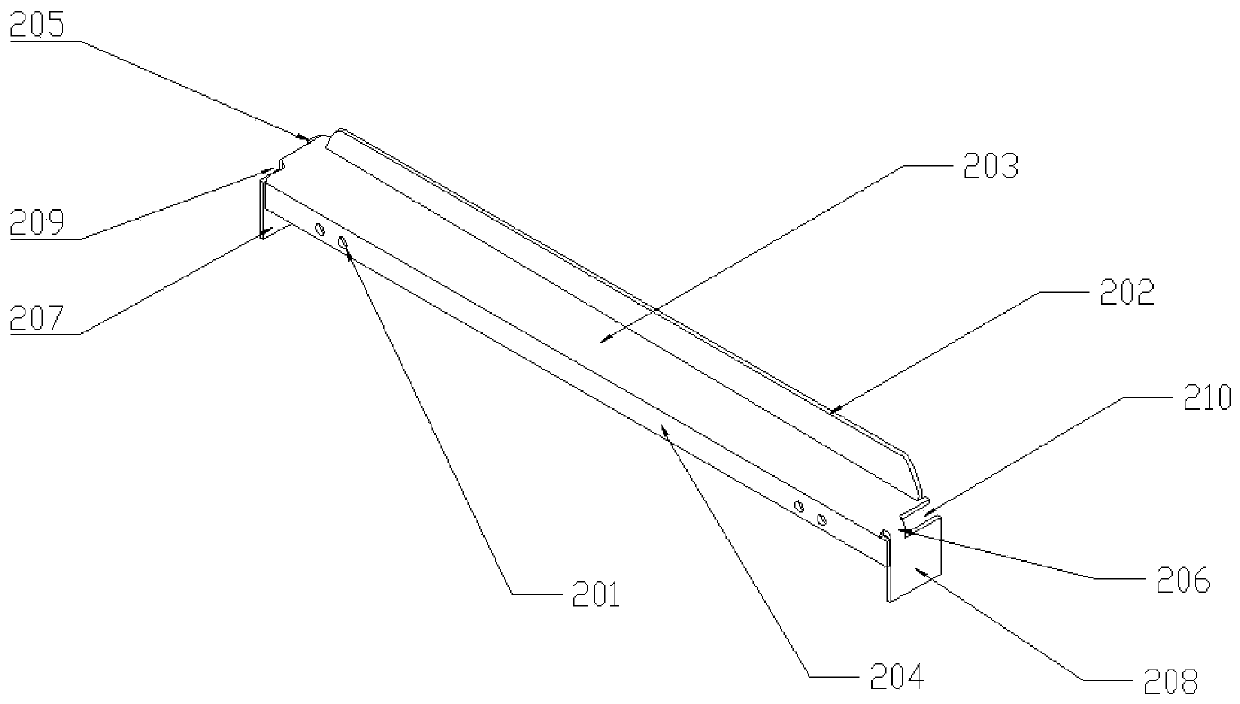

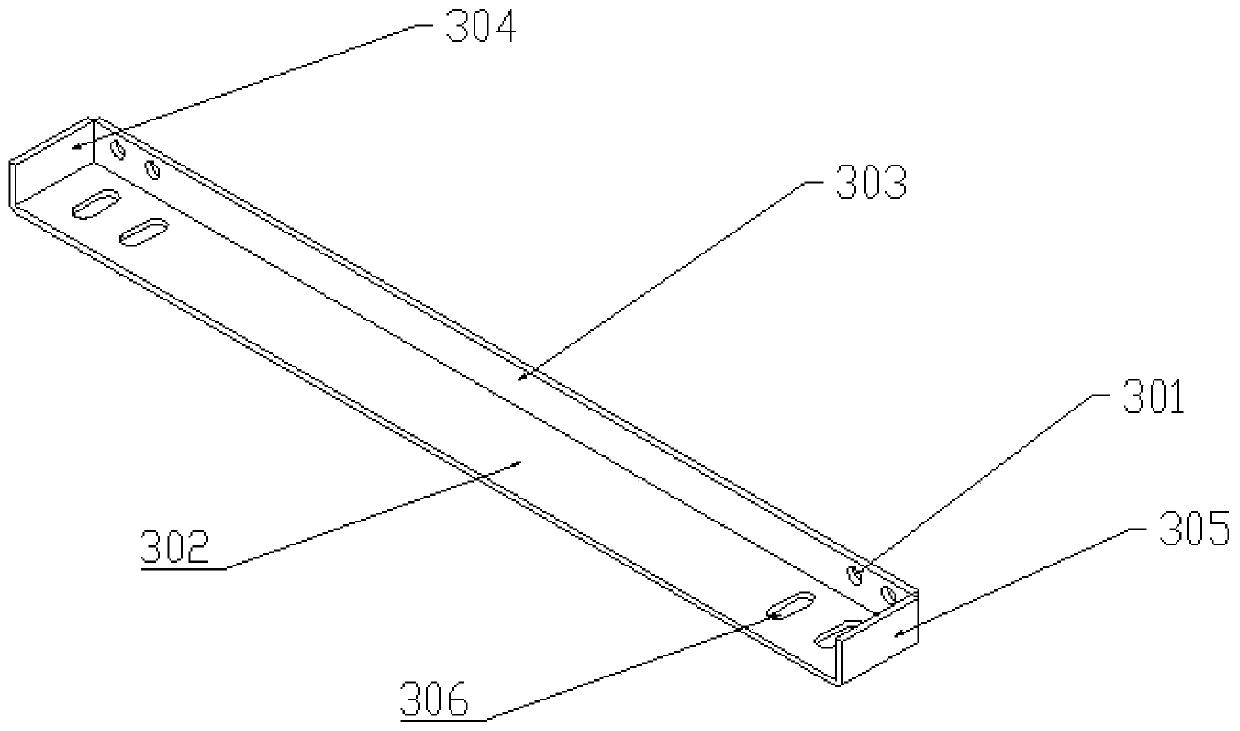

The invention provides a distribution device and a distribution system. The distribution device comprises a bottom plate, a guide rail, a mounting frame, a push-moving block, a vertical-moving block, a transverse-moving block and a mechanical grip. The mounting frame is disposed on the guide rail which is mounted on the bottom plate, the vertical-moving block is mounted on the push-moving block which is mounted on the mounting frame, the transverse-moving block is mounted on the mounting frame and connected with the bottom plate, and the mechanical grip is mounted on the vertical-moving block. The distribution system comprises a frame and at least one distribution device mounted on the frame, and the distribution devices are identical in placement direction and share the same guide rail, the same bottom plate and a same ordering device. By means of the distribution device and the distribution system, a function of delivering processed goods to different delivery lines can be realized. The distribution device and the distribution system have the advantages of simple structure, functional maturation and high practicability and can be applied to automatic industrial production, and production operational efficiency can be greatly improved.

Owner:AD TOYO LIGHTING GUANGZHOU

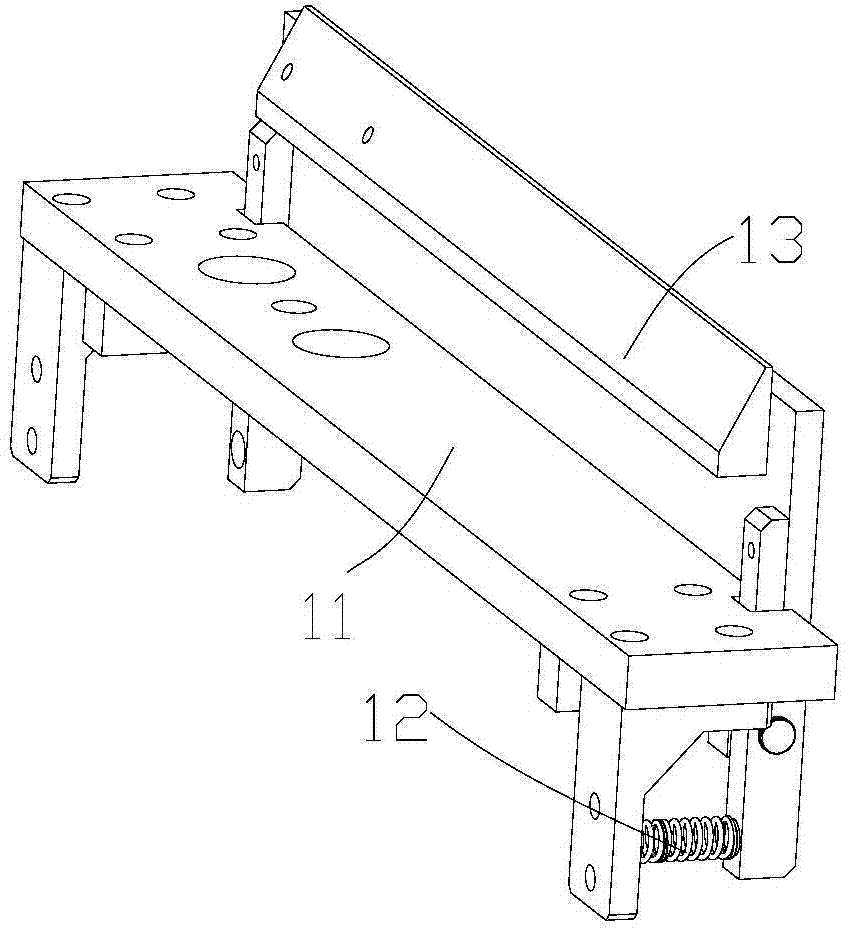

Floor for lying of sow parturition fence

The invention provides a floor for lying of a sow parturition fence. The floor comprises a dropping board body, a first support frame, a second support frame, a first special-shaped support steel barand a second special-shaped support steel bar. The special-shaped support steel bars are of bending structures formed by one-step stamping, and are provided with bayonets at equal intervals, wherein the bayonets are used for staggered and embedded connection of piglet dropping boards. The floor is supported by the special-shaped support steel bars, production components are reduced, materials areutilized to the greatest extent, welding procedures are reduced, and the high load bearing effect is ensured. The floor is novel in structure and convenient and rapid to mount, the production operation efficiency is improved, the effects of bearing load and pressure and dropping dung are good, the floor is safe, reliable sturdy and durable, and sows do not waggle when moving on the floor.

Owner:JIANGXI ZENG XIN HUSBANDRY TECH CO LTD

Automatic glue spraying and compounding machine for automobile trunk carpet production and production method

ActiveCN104527203BReduce meltingReduce the temperatureLaminationLamination apparatusEngineeringVertical displacement

The invention discloses an automatic glue spraying and compounding all-in-one machine and a manufacturing method for automobile trunk carpet production. A template of the automatic glue spraying and compounding all-in-one machine is moved by a horizontal sliding mechanism so that the purpose of horizontal displacement glue spraying of a polypropylene cellular board on the template can be achieved through a glue spraying device. The glue spraying device is moved by a vertical sliding mechanism so that the purpose of vertical displacement glue spraying of the polypropylene cellular board on the template can be achieved through the glue spraying device. Meanwhile, the glue sprayed polypropylene cellular board on the template is glued to a sound insulation felt. The glued sound insulation felt and the polypropylene cellular board on the template are quickly transferred to the position below a pressing plate by the horizontal sliding mechanism. The pressing plate is automatically activated and quickly pushed by a power unit so that further pressing, compounding and molding can be carried out on the glued sound insulation felt and the polypropylene cellular board. According to the automatic glue spraying and compounding all-in-one machine and the manufacturing method for the automobile trunk carpet production, the compounding fastness and the production efficiency of an automobile trunk carpet are improved, and the compounded and molded automobile trunk carpet is good in operation performance.

Owner:NINGBO SUNLIGHT MOTOR PARTS

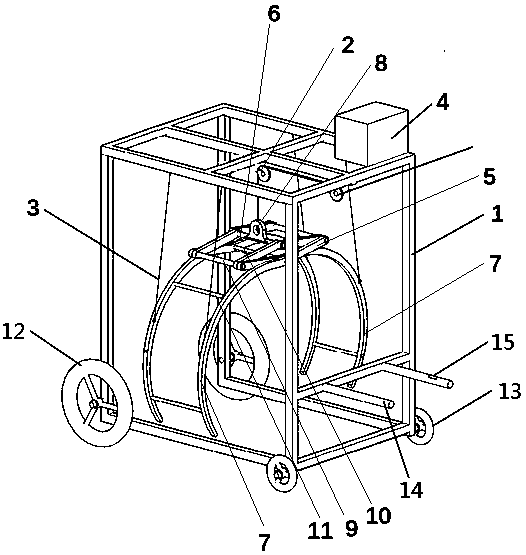

Automatic carrying system for coloring process

ActiveCN105460601AImprove the efficiency of production operationsReduce labor intensityConveyor partsSystem usageEngineering

Owner:江苏亨芯石英科技有限公司

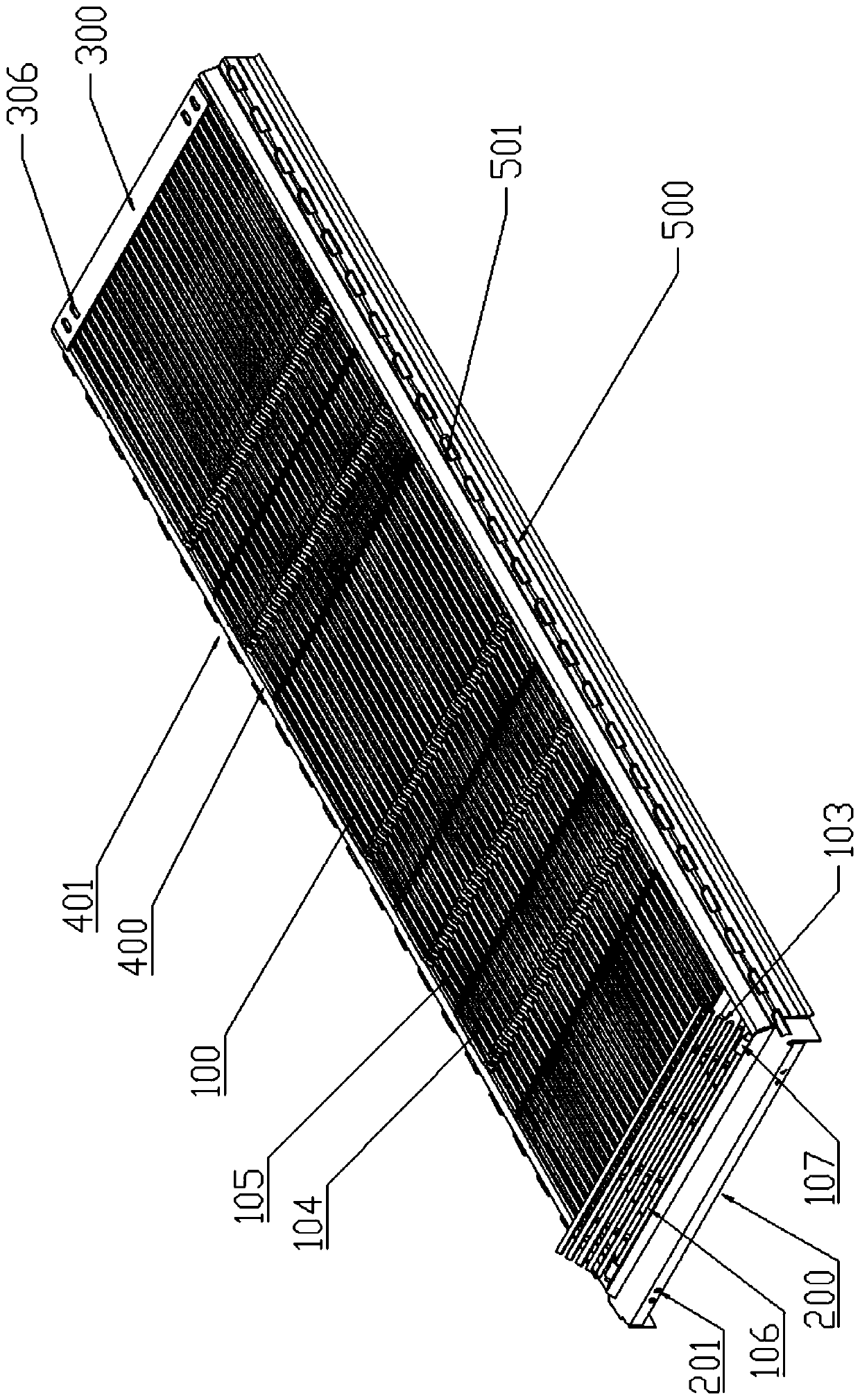

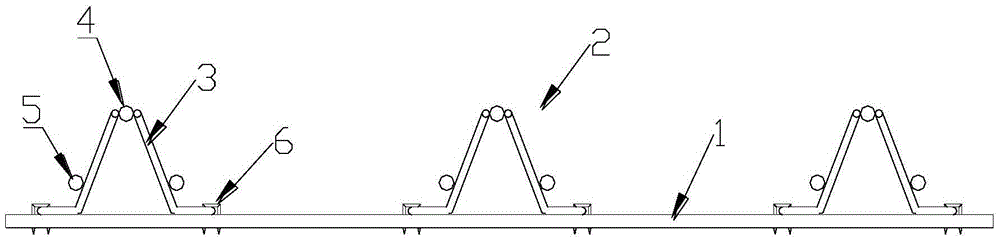

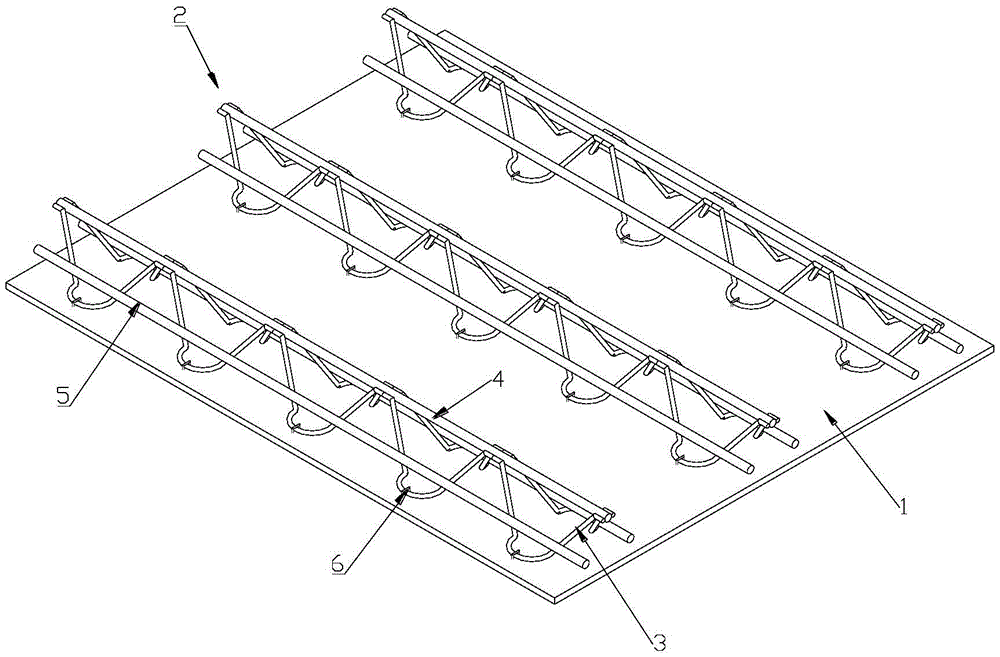

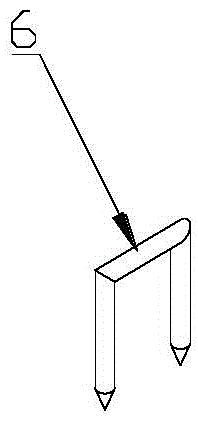

Combination formwork composed of steel bar trusses and bottom die

The invention discloses a combination formwork composed of steel bar trusses and a bottom die. The combination formwork comprises the nonmetal bottom die. The multiple steel bar trusses are arranged on the nonmetal bottom die. Each steel bar truss comprises a space curve-shaped web bar. An upper bar is arranged on the top of each web bar. The two sides of each web bar are each provided with a bottom bar. Each upper bar and the corresponding bottom bars are distributed in a triangular mode. The steel bar trusses and the nonmetal bottom die are connected through a plurality of tie bars. The tie bars are connected with the nonmetal bottom die through the web bars or the bottom bars. The height of the web bars is larger than that of the triangles formed by the upper bars and the bottom bars. According to the combination formwork composed of the steel bar trusses and the bottom die, the bottom is flat and smooth, construction is completed, the appearance quality is good even when no processing is performed, the combination formwork is easy to operate, industrial assembly line production is facilitated, the production operation efficiency is greatly improved, manpower and material resources are saved, and the formwork decreases a large amount of occupied space and greatly improves the conveying efficiency.

Owner:SHANGHAI OPEN STEEL JOIST

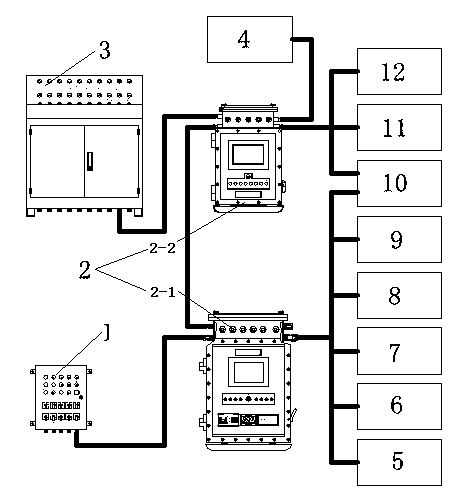

Automatic draining device for mines

InactiveCN103291356AAutomatic control start and stopImprove the efficiency of production operationsPump controlDrainageAutomatic controlControl room

The invention discloses an automatic draining device for mines, and belongs to the technical field of mine draining. The device comprises a control box, programmable controllers and a general operating platform. The programmable controllers include a first programmable controller connected with the control box and a second programmable controller connected with the general operating platform. The second programmable controller is connected with a remote central control room. The first programmable controller is connected with a valve electro-hydraulic actuator, a stroke and micro switch, a temperature sensor, a flow meter, a pressure transmitter and a soft starting cabinet operating platform of a water pump motor respectively. The second programmable controller is connected with a float switch, an operating platform of a liquid level sensor and the soft starting cabinet operating platform of the water pump motor respectively. Through real-time monitoring and controlling of the programmable controllers, starting and stopping of a water pump can be automatically controlled, manual guard is completely replaced, and losses caused by manual misoperations are avoided while production operating efficiency is improved.

Owner:江苏金宏泰科技股份有限公司

Complex modified starch

The invention provides complex modified starch which is prepared from the following main ingredients in portion by weight: 100 portions of starch, 1-10 portions of 1-25% sodium hypochlorite, 1-10 portions of 1-25% sodium metabisulfite, 1-10 portions of acetyl oxide, 1-40 portions of 1-40% NaOH and 50-250 portions of water. In the reaction process of the complex modified starch, carboxyl and acetyl groups are introduced to the starch molecules, so the starch molecules have the characteristics of hydrophilicity and lipophilicity simultaneously, have the functions of emulsification and dispersion, and can emulsify water and grease brought in the production process of chocolate products to form a very stable structure.

Owner:聚祥(厦门)淀粉有限公司

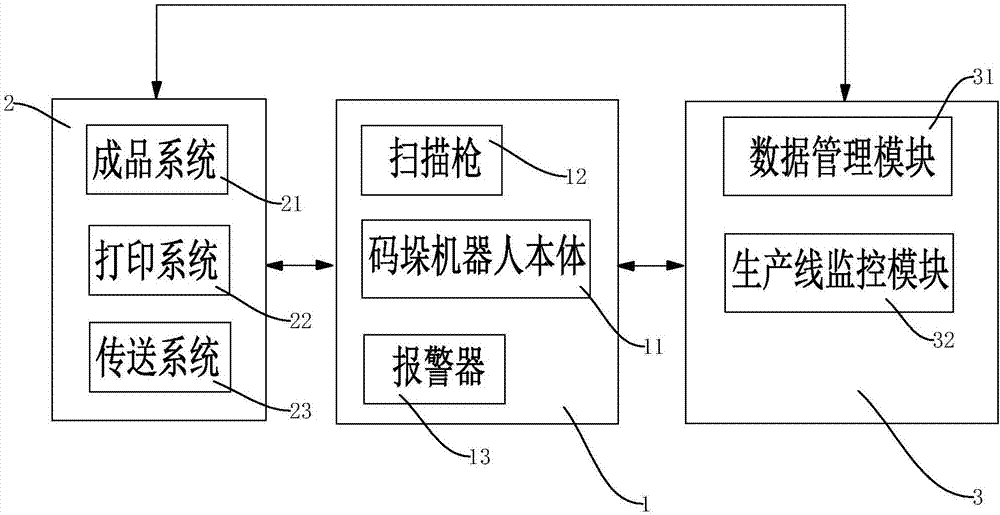

Palletizing robot interactive system

PendingCN108002050AImprove the efficiency of production operationsAutomate operationsConveyorsStacking articlesProduction lineProduct system

The invention discloses a palletizing robot interactive system. The palletizing robot interactive system comprises a palletizing robot, a production line and an MES, and the MES is used for sending label barcode information to the palletizing robot and the production line separately; the production line includes a finished product system, a printing system, and a delivery system, the finished product system is used for producing products, the printing system is used for manufacturing the label barcode information sent by the MES into label barcodes and affixing the label barcodes to the products and packaging boxes packaging the products, and the delivery system is used for transferring the products and the package boxes with the label barcodes to the palletizing robot for processing; andthe palletizing robot is used for determining whether the label barcode information of the products and the packaging boxes is consistent and performing corresponding operation. The automated operation of production and packaging can be realized through the design, the production operation efficiency of a factory is improved, and the one-to-one correspondence of the information of the products andthe packaging boxes is simultaneously realized; when a certain product has a quality problem, the packaging box can be immediately found, thereby improving the work efficiency.

Owner:ZHONGSHAN LINGCHUANG NETWORK TECH CO LTD

Super battery and negative electrode plate thereof

PendingCN109546155ALow costReduce deliveryCell seperators/membranes/diaphragms/spacersElectrode carriers/collectorsEngineeringElectrode

The invention discloses a negative electrode plate comprising a grid substrate disposed inside a battery casing, and a front paste layer and a back paste layer coating the front and back sides of thegrid substrate respectively, wherein the grid substrate is a punched grid, the front paste layer and the back paste layer are wrapped in a composite separating plate. The negative electrode plate haslow cost and a firm carbon paste layer, and can ensure that a super battery has good capacity and high production operation efficiency. The present invention also discloses a super battery including the negative electrode plate.

Owner:SHANDONG SACRED SUN POWER SOURCES

Intelligent charging pile mainframe control system and assembly and test method

PendingCN106786970AImprove the efficiency of production operationsReduce production operation requirementsIndicating/monitoring circuitsElectrical testingControl systemMan machine

The invention provides an intelligent charging pile mainframe control system. The intelligent charging pile mainframe control system provides a display screen. When the staff installs and maintains the system, the staff can know that the working status and fault of the charging pile connected with the intelligent charging pile mainframe through the display screen. The intelligent charging pile mainframe control system provides a subaddress unit. The subaddress unit is arranged on a charging pile of the electric bicycle. The subaddress unit is connected with a charging pile mainframe control unit through the address data line signal. According to the address of the faulted charging pile, the charging pile mainframe control unit is arranged for shielding all circuits of the faulted charging pile. At the same time, other charging piles continues working. The intelligent charging pile mainframe control system provides a touching-type display screen with virtual key or a entity key unit, so a channel of man-machine intercourse is provided for the staff.

Owner:ZHEJIANG LINJU SMART TECH CO LTD

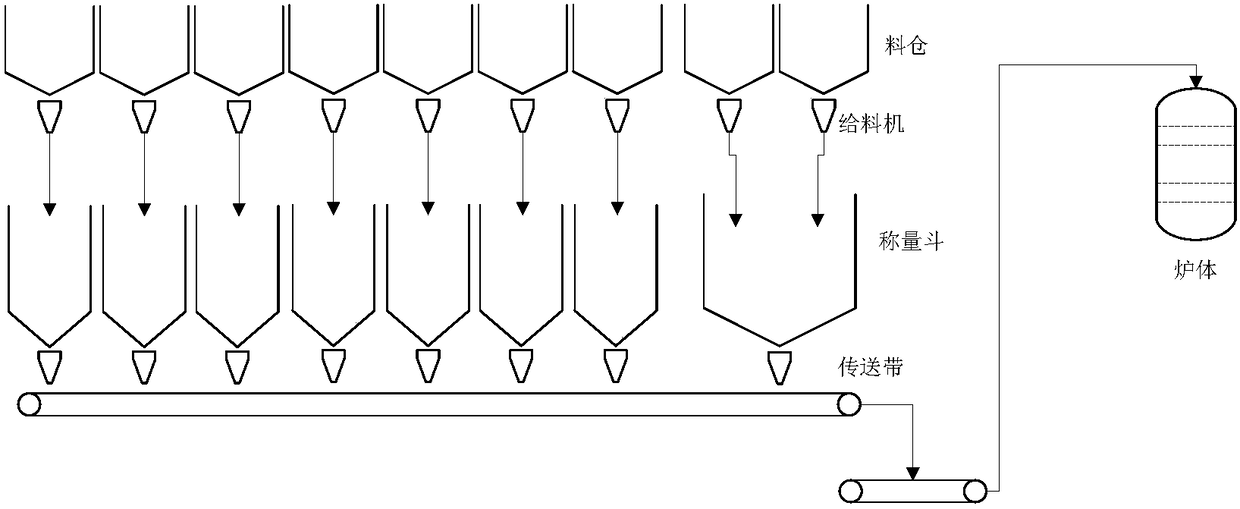

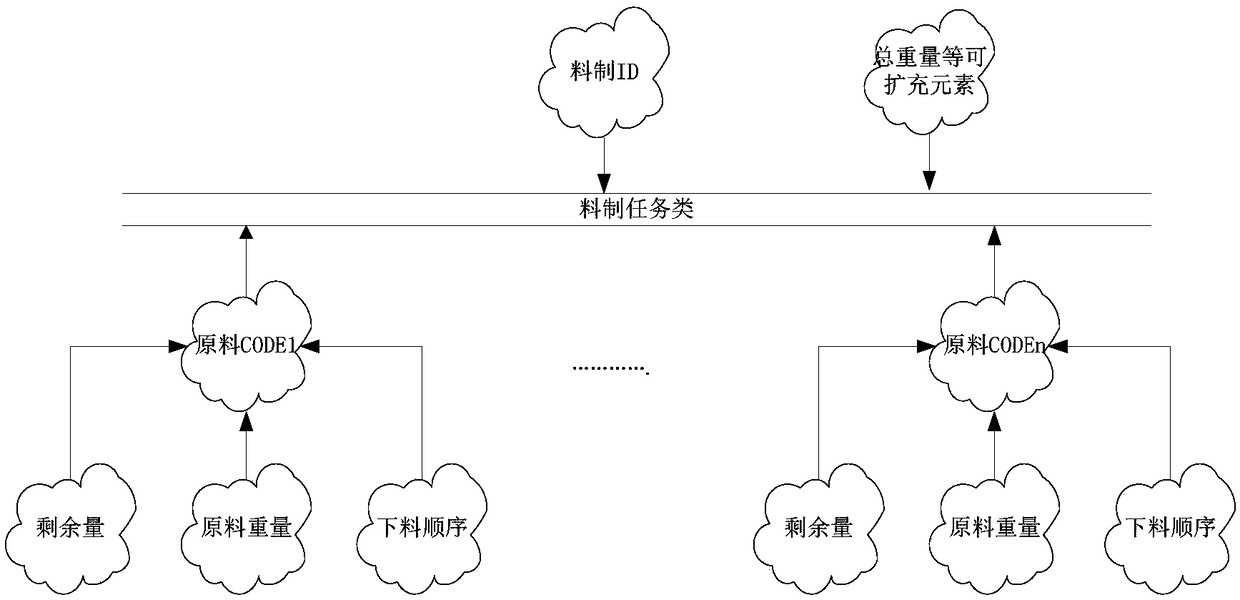

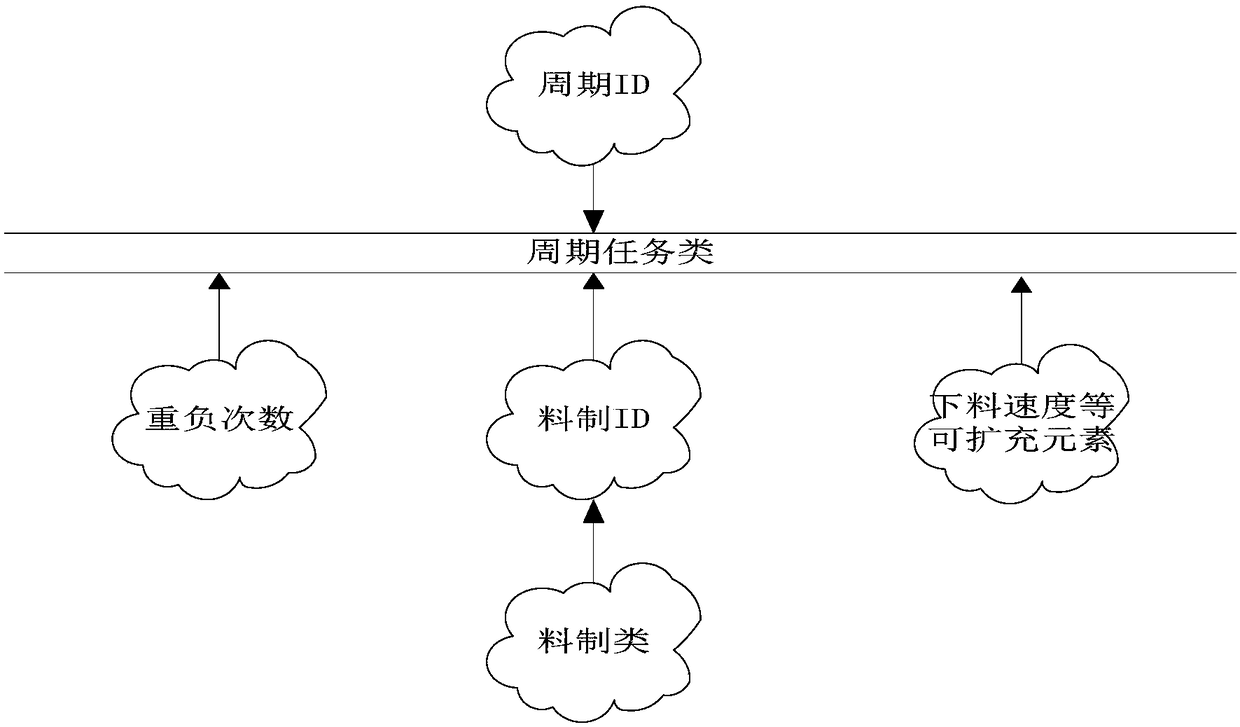

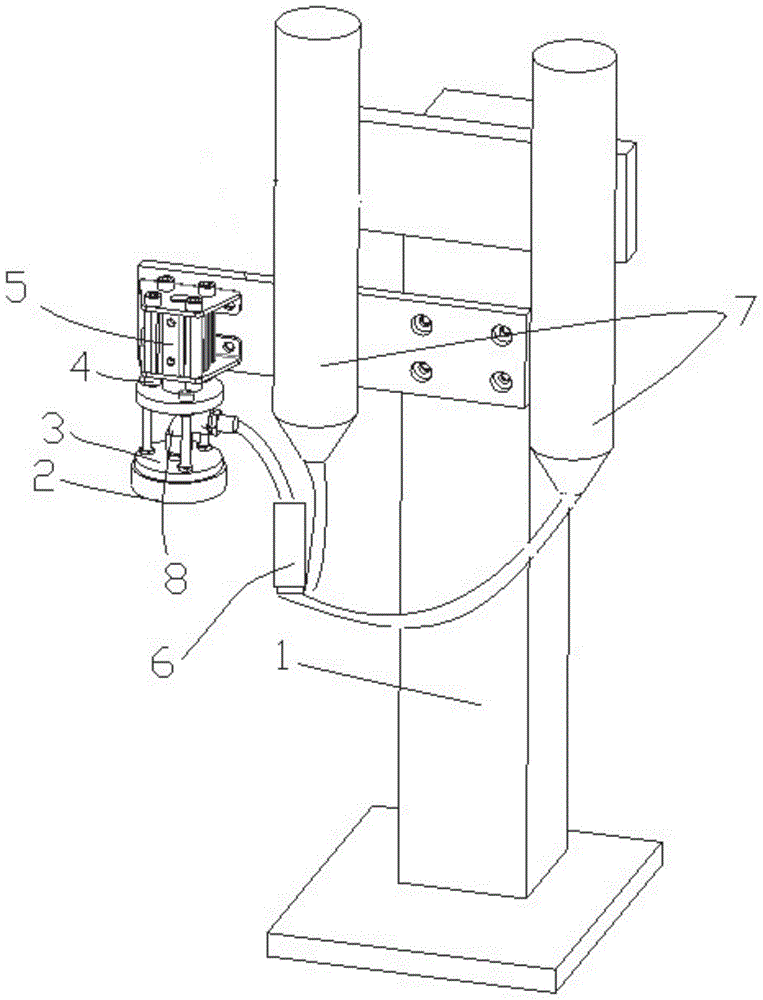

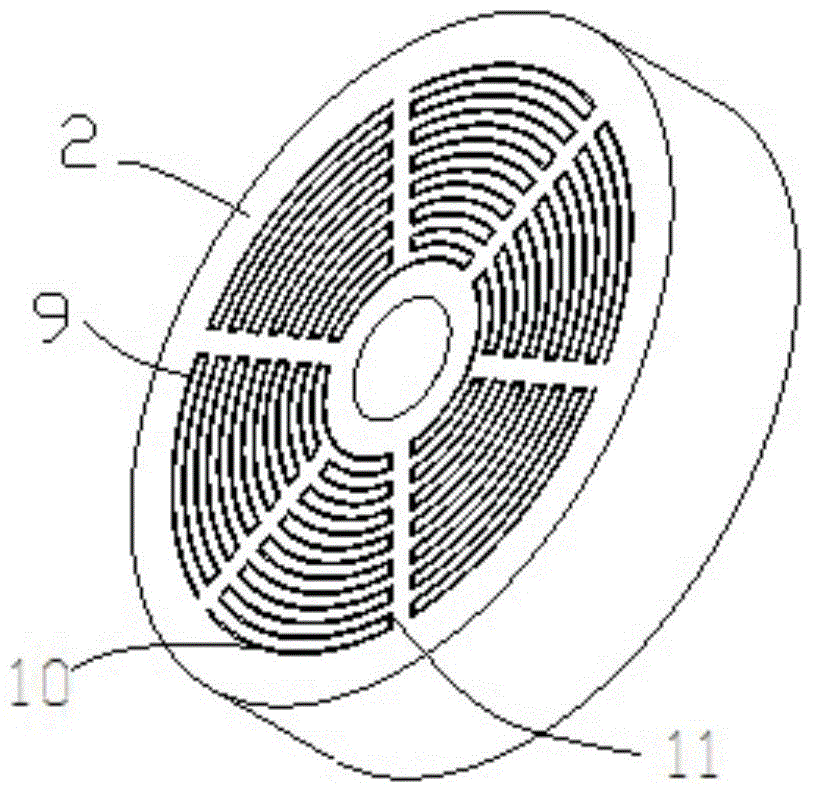

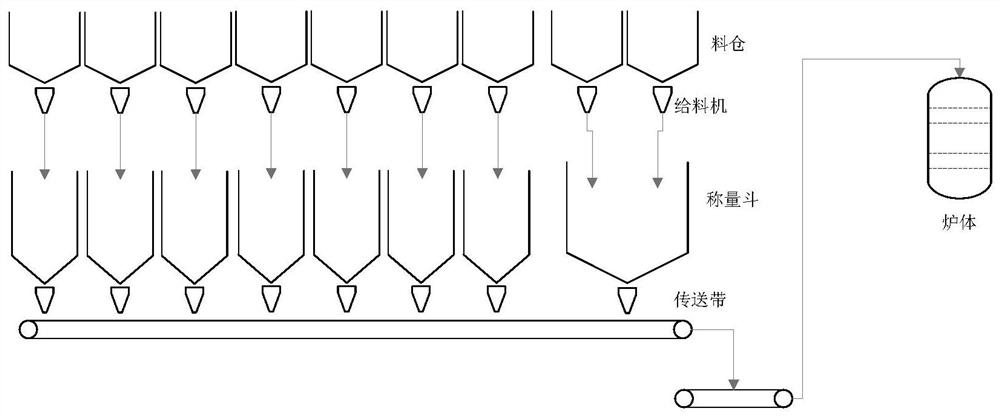

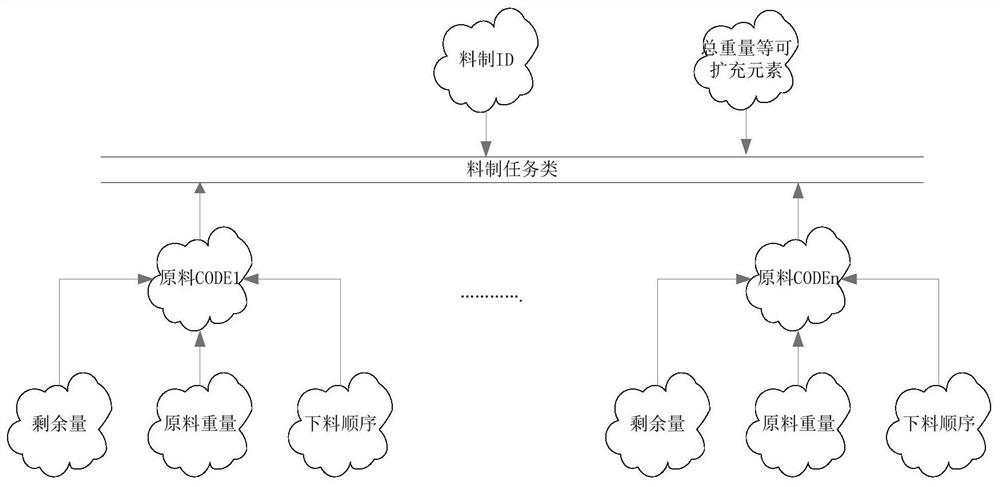

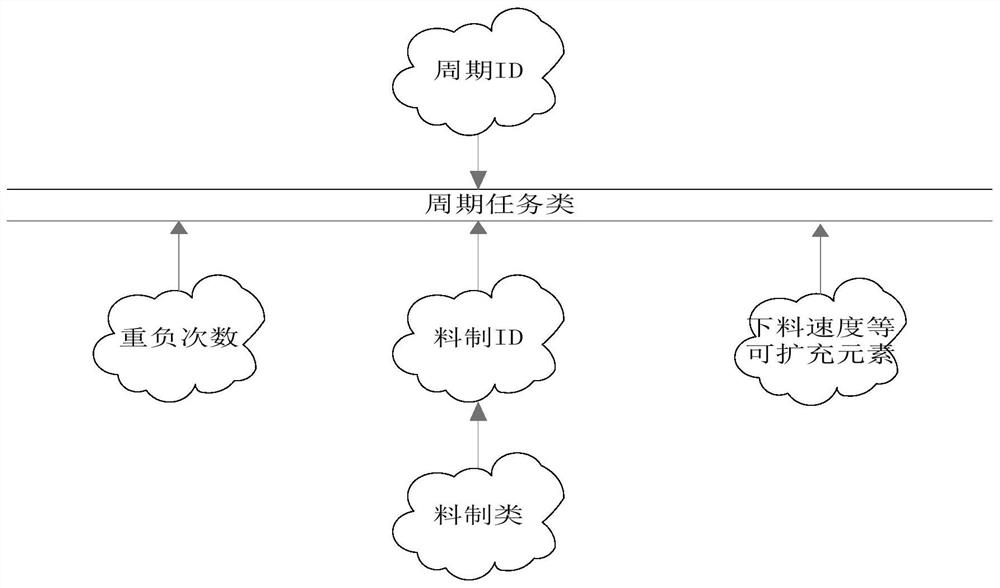

The utility model relates to a distribution process of the ingredients under a tank

ActiveCN109388444AImprove the efficiency of production operationsStrong production adaptabilityBlast furnace detailsExecution for user interfacesMaterials preparationAdditive ingredient

The invention discloses an under-tank batching distribution process, which comprises the following steps: establishing a data structure of a material preparation class in a control system and realizing the data structure to obtain a material preparation class for HMI display and editing, and a stored material preparation class; the data structure of the material preparation class is set up in thecontrol system; the data structure of the material preparation class is set up in the control system. In the control system, the periodic data structure is set up according to the requirement and thedata structure is realized to obtain the display editing instance for screen display and editing, the execution instance for background execution, and the performance instance for tracking the execution status. In HMI system, design the material editing and display screen according to the requirement; In the HMI system, the required batching screen is designed according to the requirements, and the operation of the batching screen is developed according to the selection menu. Editing and storing operations of material preparation in the batching screen; The batching list is edited and displayed on the batching screen. The invention solves the problem that it is difficult to adapt the raw material when the batching list under the tank is simply fixed, improves the production adaptability ofthe smelting furnace and improves the efficiency of the batching production operation.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD

a line management mechanism

Disclosed is a smart production system of an LED lamp, the system comprising an automatic assembling mechanism (5), an automatic aging mechanism (4) connected to the automatic assembling mechanism (5), an automatic detecting device (2) connected to the automatic aging mechanism (4), an automatic packaging device (1) connected to the automatic detecting device (2), an automatic conveying device (3) connected to the automatic packaging device (1), and a master control unit which is connected to the automatic packaging mechanism (5), the automatic aging mechanism (4), the automatic detecting device (2), the automatic packaging device (1) and the automatic conveying device (3). The system successively, along a guide rail, comprises: a lamp body wiring device, a lamp holder installing device, an electrical board installing device, a wire management device, a wire bending and pressing device, a lamp holder and outer sleeve integrating device, an adhesive coating device, a light source board assembling device, a circuit welding device and a lampshade assembling device. Performing automated design on various processes greatly saves the cost of human resources and enhances the production efficiency.

Owner:AD TOYO LIGHTING GUANGZHOU

Lifting and transverse moving mechanism for logistics storage and working method thereof

PendingCN112707076AImprove the efficiency of production operationsStorage devicesConveyor partsLogistics managementControl theory

Owner:SHANGHAI HEYI LOGISTICS

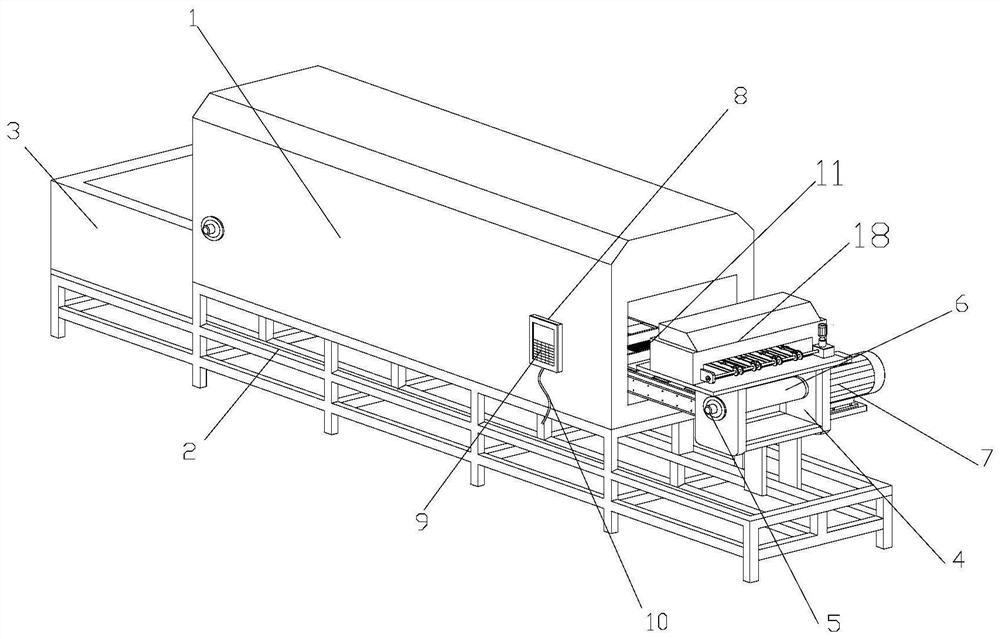

Varnish baking device adopting high-frequency heating manner

InactiveCN113019847AEasy to hold and transportImprove the efficiency of production operationsPretreated surfacesCoatingsElectric machineTransmission belt

The invention discloses a varnish baking device adopting a high-frequency heating manner. The varnish baking device comprises a baking bin, a bottom frame, a waiting groove, a supporting frame, a rotating shaft, a transmission belt, a first motor, an electric control panel, a control key, a power line, a position plate, an inner frame, a fan, a high-frequency electric heating pipe, a separation net, an outlet, an inclined plate and a displacement assembly. According to the varnish baking device, the displacement assembly is arranged, hairpins are conveyed and subjected to varnish baking through a hairpin conveying assembly, the hairpins are clamped and moved out through a hairpin moving assembly, all electrifying parts are automatically electrified through a control assembly, a hairpin suction assembly is made to make moving contact with the hairpins in a slight force application manner, and the contact surfaces are protected, so that automatic varnish baking, heating and baking treatment can be conveniently and effectively conducted on the hairpins, labor waste is reduced, the painting stability of hairpin bodies is improved, and the rate of finished products is increased.

Owner:ZHANGZHOU BEITE COSTUME

A distribution device and system

InactiveCN103754638BSimple structureVersatileConveyor partsDistribution systemIndustrial engineering

The invention provides a distribution device and a distribution system. The distribution device comprises a bottom plate, a guide rail, a mounting frame, a push-moving block, a vertical-moving block, a transverse-moving block and a mechanical grip. The mounting frame is disposed on the guide rail which is mounted on the bottom plate, the vertical-moving block is mounted on the push-moving block which is mounted on the mounting frame, the transverse-moving block is mounted on the mounting frame and connected with the bottom plate, and the mechanical grip is mounted on the vertical-moving block. The distribution system comprises a frame and at least one distribution device mounted on the frame, and the distribution devices are identical in placement direction and share the same guide rail, the same bottom plate and a same ordering device. By means of the distribution device and the distribution system, a function of delivering processed goods to different delivery lines can be realized. The distribution device and the distribution system have the advantages of simple structure, functional maturation and high practicability and can be applied to automatic industrial production, and production operational efficiency can be greatly improved.

Owner:AD TOYO LIGHTING GUANGZHOU

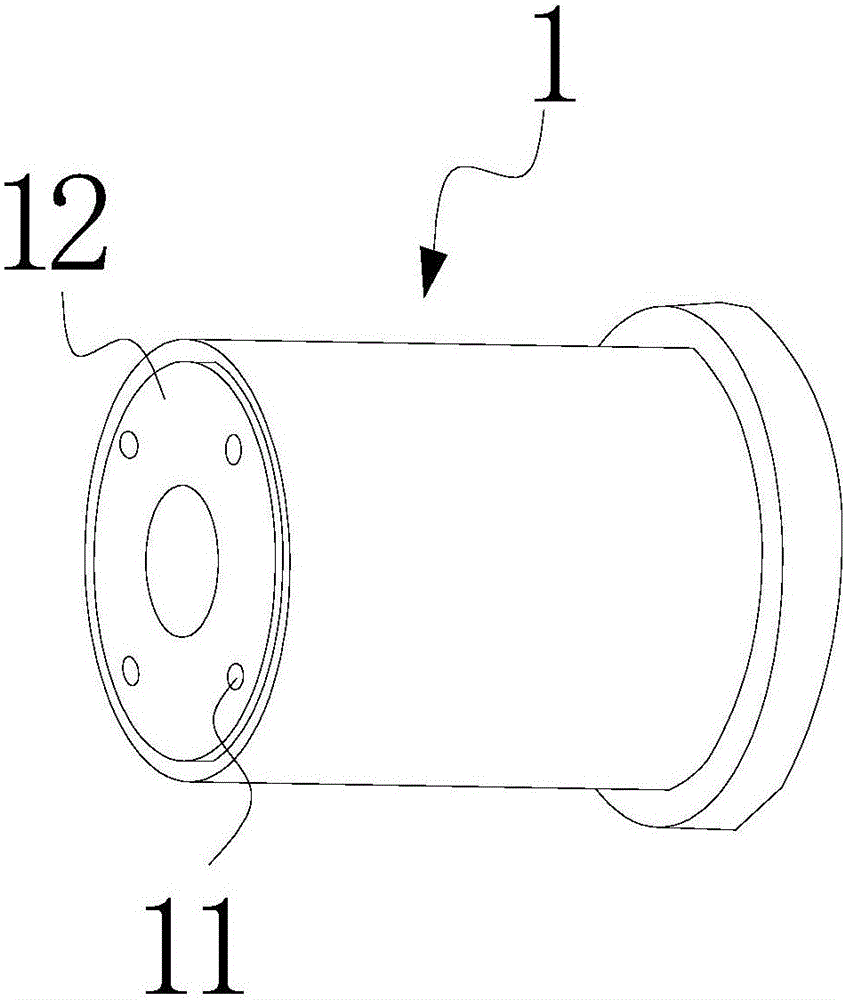

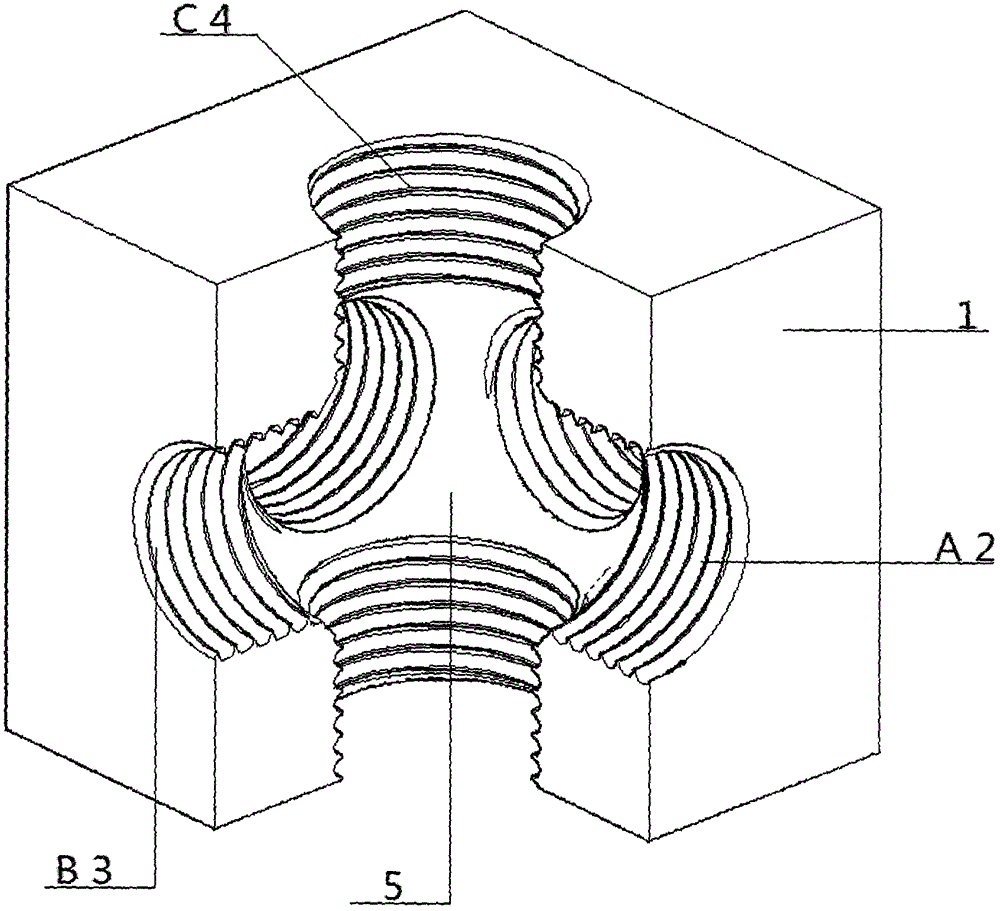

Variable diameter dies on pipe production line

The invention belongs to the field of pipe production lines, in particular to a reducing mold on a pipe production line. The reducing mold on the pipe production line comprises a neck mold and a core mold that are mounted on an extruder body. The reducing mold is characterized by further comprising an end plate and an entirety columnar core mold end head, wherein the end plate is detachably fixed at an extrusion end of the neck mold; a penetrable hole communicated with the neck mold is formed in the end plate; a center convex column is fixedly arranged at one end of the core mold end head and provided with external threads; a tightening part to tightly screw the external threads is arranged at the other end of the core mold end head; internal threads matched with the external threads are formed at one end, close to the neck mold, of the core mold; the center convex column of the core mold end head penetrates through the penetrable hole and is in threaded connection with the core mold; a main body part of the core mold end head traverses into the penetrable hole; and a clearance for extruding a pipe is reserved between the main body part and an internal wall of the penetrable hole. The reducing mold on the pipe production line is more convenient and quicker to use and can improve production efficiency.

Owner:CHONGQING WEIXING NEW BUILDING MATERIALS

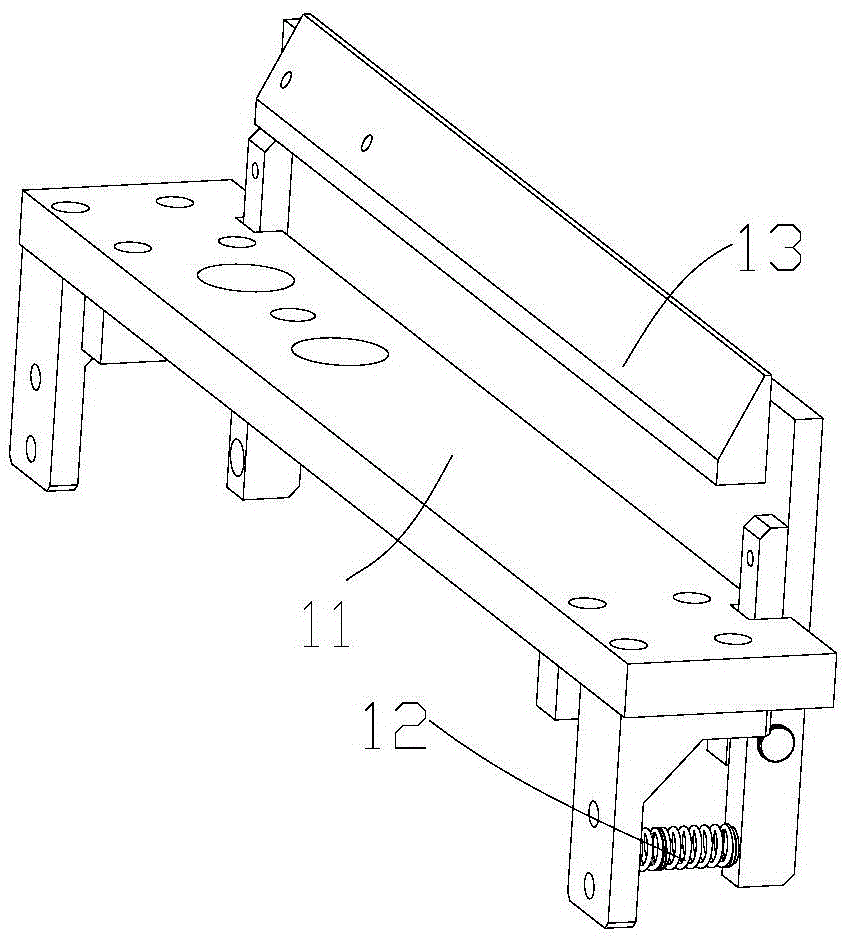

a gluing mechanism

InactiveCN103831208BWill not flow backReduce power consumptionLiquid surface applicatorsCoatingsSufficient timeEngineering

The invention provides a gluing mechanism, comprising a support, glue conveying cylinders, a non-return valve, a joint, an air cylinder, a connection support, a sleeve plate and a gluing panel, wherein the glue conveying cylinders are installed on the support, the upper end of each glue conveying cylinder is an input end, the lower end of each glue conveying cylinder is an output end, a dispensing machine is connected with the input ends of the glue conveying cylinders, the input end of the non-return valve is connected with the output ends of the glue conveying cylinders, the output end of the non-return valve is connected with the joint, the joint is mounted on the sleeve plate, the air cylinder is installed on the support, the connection support is connected with the air cylinder, the sleeve plate is mounted on the connection support, and the gluing panel is threadedly fixed with the sleeve plate. The gluing mechanism provided by the invention can realize uniform gluing; a glue solution does not flow back in the process of gluing, repeated conveying is avoided, energy is saved, and power consumption is reduced; through switching between the double glue conveying cylinders, there is sufficient time for filling of the glue conveying cylinders with the glue solution; the residual amount of the glue solution in the cylinders can be sensed. The gluing mechanism has a simple structure and good practicality.

Owner:AD TOYO LIGHTING GUANGZHOU

A distributing process of batching under the trough

ActiveCN109388444BImprove the efficiency of production operationsStrong production adaptabilityBlast furnace detailsExecution for user interfacesControl systemAdditive ingredient

The invention discloses a process for distributing ingredients under a trough, which includes: establishing and classifying the data structure of the material system class in the control system, obtaining the material system class used for HMI display and editing, and the data structure used for storage Material system; in the control system, establish a periodic data structure according to the requirements and carry out real classification, and obtain the display editing instance for screen display and editing, the execution instance for background execution, and the actual performance instance for tracking execution status; in the HMI Design material system editing and display screens in the system according to requirements; design the required batching screens in the HMI system according to requirements, and develop the operation of the batching screens based on the selection menu as the development principle; perform editing and storage operations on the batching screens; Edit and display the ingredient list on the ingredient screen. The invention solves the problem that it is difficult to adapt to raw materials when the batching list under the tank is simply fixed, improves the production adaptability of the smelting furnace, and improves the efficiency of batching production operation.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD

A mechanical turning hand

The invention provides a mechanical overturning arm. The mechanical overturning arm comprises a support, a mechanical arm, a motor, an adjusting air cylinder and a clamping device, wherein the motor is fixed to the support, one end of the mechanical arm is rotationally installed on the motor, and the other end of the mechanical arm is provided with the adjusting air cylinder; the clamping device is fixed to the adjusting air cylinder. The mechanical overturning arm can carry workpiece products between different work stations, and even when the work stations or assembly lines are located at positions of different heights, the mechanical overturning arm can fast achieve carry operation. The mechanical overturning arm has the advantages of being simple in structure, complete in function, high in practicality and universality and capable of being applied to automatic industrial production and greatly improving production and operation efficiency.

Owner:AD TOYO LIGHTING GUANGZHOU

A kind of preparation method of high-strength and low-static ctp plate backing paper

ActiveCN111608010BStable moisture contentUniform sizeNon-fibrous pulp additionPaper/cardboardCellulosePapermaking

The invention relates to the technical field of papermaking. Aiming at the problems of not effectively controlling the static range and tensile strength of CTP plate interleaving paper, a preparation method of high-strength and low-static CTP plate interleaving paper is proposed. Including: (1) Preparation of slurry: mixing and beating raw material slurry and auxiliary agents to prepare slurry; (2) Pre-treatment of sizing: Dewatering, pressing and pre-drying the mixed slurry in sequence through the wire part to obtain raw materials (3) Sizing: enter the surface sizing treatment process, and use aminocellulose-vermiculite-modified styrene-acrylic emulsion to perform surface sizing on the raw paper described in step (2); (4) post-sizing treatment: After surface sizing, it is dried in sections, calendered, and rolled up. The CTP version of the backing paper has a suitable moisture content, which ensures that the surface of the backing paper has a certain amount of static electricity and has strong tear resistance. The backing paper has excellent waterproof effect, low stretch rate, high strength and small thickness difference , the preparation process is simple and efficient.

Owner:XIANHE CO LTD

a conveyor line

The invention provides a conveying line which comprises a conveying device, a track transferring device, a track blocking plate and a gate component. The track transferring device is placed at the input end of the conveying device. The track blocking plate is arranged on a first frame and placed above a first conveying belt. The gate component is mounted on the first frame and placed at the output end of the conveying device. According to the conveying line, equipment occupied space can be greatly reduced, meanwhile, production efficiency can be guaranteed, the conveying line has the advantages of being simple in structure, complete in function and high in practicability, the conveying line can be used in industrial automation production, and production operation efficiency can be greatly improved.

Owner:AD TOYO LIGHTING GUANGZHOU

Novel remote control power pressing plate and control method

PendingCN113346447ARealize drop-in controlSimple and efficient operationSwitch power arrangementsEmergency protective arrangement detailsRemote controlMotronic

The invention is applicable to the field of electric power pressing plates and provides a novel remote control electric power pressing plate. The remote control power pressing plate comprises an outer shell and a pressing plate body connected to the outer shell and provided with a first electrode, wherein the pressing plate body is provided with a pressing plate handle which is provided with a second electrode and used for controlling connection and disconnection of the first electrode and the second electrode; one end of the rotating shaft component is connected to the pressing plate handle, the electric component is used for driving the pressing plate handle so that the first electrode and the second electrode can be switched between the on state and the off state, and a clutch device is arranged between the electric component and the pressing plate handle; the clutch device is connected to the other end of the rotating shaft component, and the electric component and the clutch device are both arranged in the outer shell. The invention further provides a control method for the novel remote control power pressing plate. According to the novel remote control power pressing plate and the control method provided by the invention, production operation efficiency is improved, and safety and reliability are good.

Owner:CYG CONTRON

A carbon product transporting truck

InactiveCN109204414AImprove the efficiency of production operationsAvoid complex structuresSupporting partsHand carts with multiple axesVehicle frameCarbon product

The invention discloses a carbon product transporting truck, which comprises a frame, rollers, a fixture, an electric hoist, a guide rope and a power supply. The frame is an internal hollow frame body, and a side bottom end of the frame is connected with the bottom surface of the frame in a through manner. The electric hoist is connected below the top of the frame, is connected with a top end of the fixture, and is connected with the power supply. The rollers are symmetrically arranged on both sides of the bottom of the frame. With the joint action of guide rope and fixture, the clamping operation of the fixture for carbon products is simple, and the tension of the guide rope controls the opening and closing of the fixture, thus avoiding the drawbacks of complex structure, easy damage andcomplex operation caused by the traditional electric control fixture. The truck has the advantages of convenient use, simple operation, small turning radius of the vehicle, flexible use, low operationcost, environmental protection and no pollution, and wide application range, and effectively improves the production and operation efficiency of the carbon products, saves the cost, avoids the collision of the products and ensures the product quality.

Owner:CHENGDU CARBON

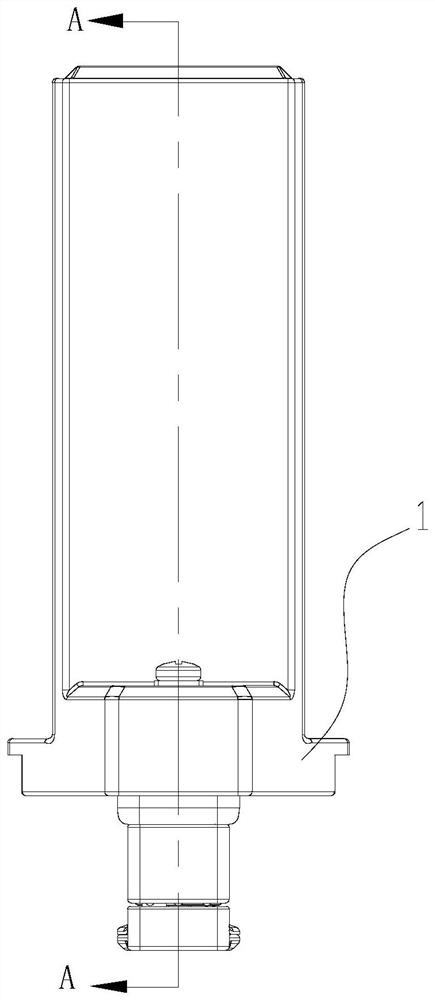

Square nut

Owner:HEFEI CHANGLING AUTO PARTS

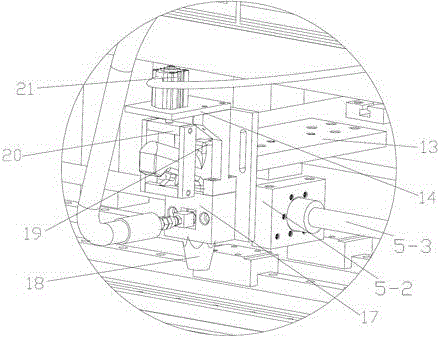

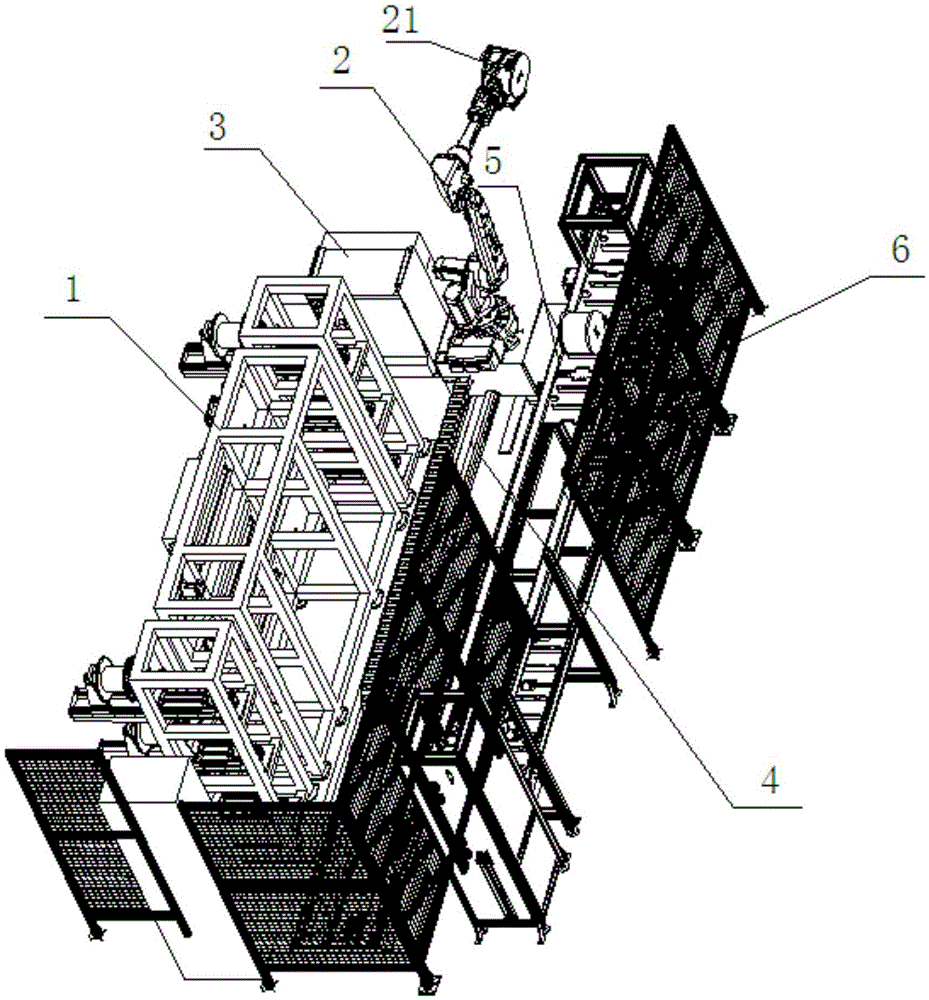

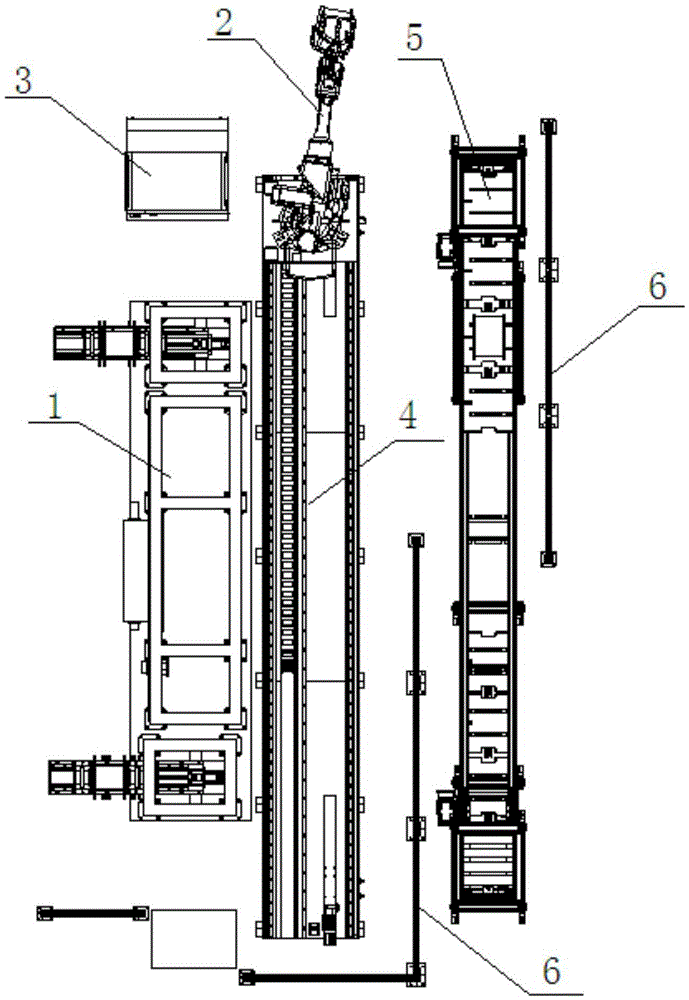

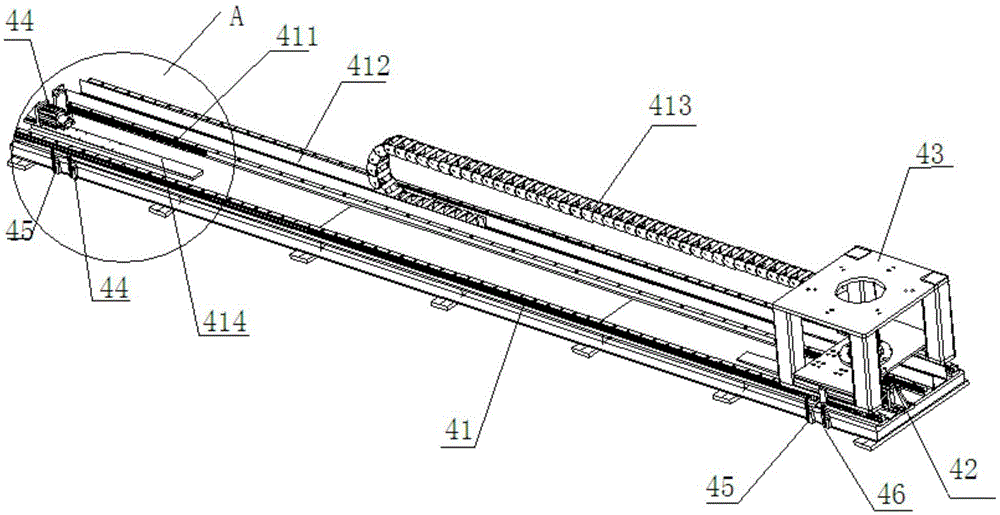

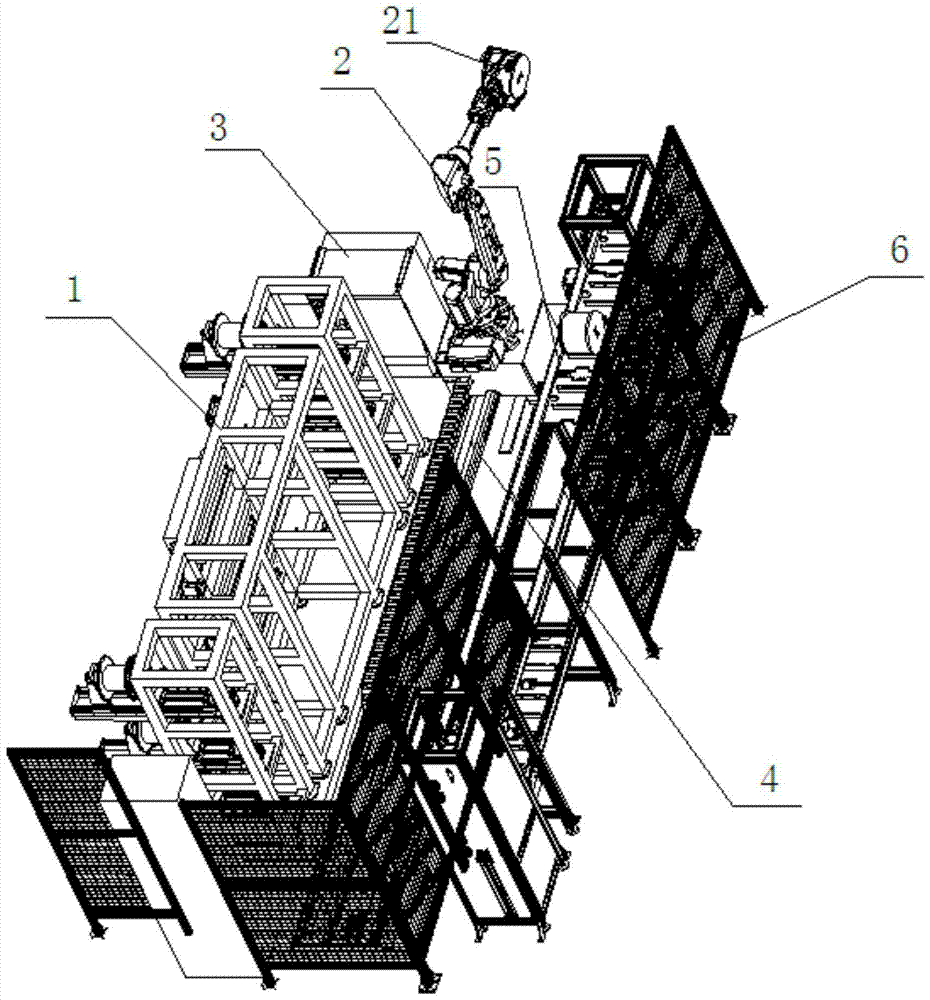

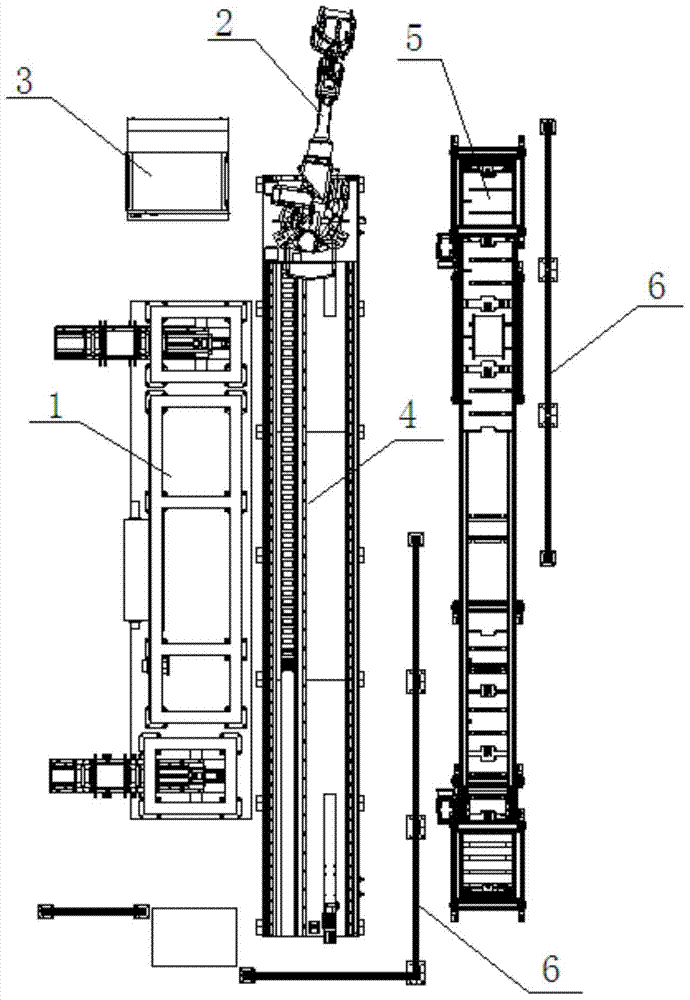

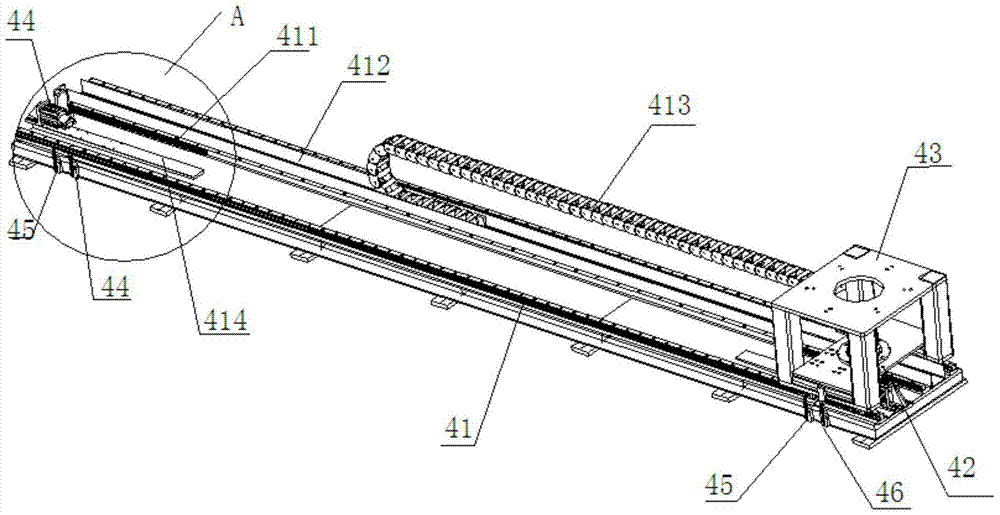

Automatic handling systems for the coloring process

The invention relates to an automatic carrying system for a coloring process. The automatic carrying system comprises a multi-head coloring machine, a robot, a control cabinet, a guide rail system used for automatically moving the robot and a conveying line for conveying wire coils. The robot moves in the guide rail system to the coil feeding position of the multi-head coloring machine for feeding the coils, after the wire coils are colored in the multi-head coloring machine, the robot moves in the guide rail system to the coil discharging position of the multi-head coloring machine for discharging the coils, and the wire coils are placed on the conveying line to be conveyed. By the adoption of the system, a mechanical device is used in cooperation with a mechanical gripper and a guide rail, and traditional labor is replaced for finishing the automatic disc feeding and discharging actions; and the system is in combination with the development of the coloring machine, following improvement and optimization of the coloring machine are accelerated, upgrading, replacement and transformation of the coloring machine are promoted, production and operation efficiency is improved after a program is implemented and finished, labor intensity is lowered, and production efficiency is improved.

Owner:江苏亨芯石英科技有限公司

A bending line mechanism

InactiveCN103934383BSo as not to damageSimple structureAssembly machinesSortingLED lampMechanical engineering

Disclosed is a smart production system of an LED lamp, the system comprising an automatic assembling mechanism (5), an automatic aging mechanism (4) connected to the automatic assembling mechanism (5), an automatic detecting device (2) connected to the automatic aging mechanism (4), an automatic packaging device (1) connected to the automatic detecting device (2), an automatic conveying device (3) connected to the automatic packaging device (1), and a master control unit which is connected to the automatic packaging mechanism (5), the automatic aging mechanism (4), the automatic detecting device (2), the automatic packaging device (1) and the automatic conveying device (3). The system successively, along a guide rail, comprises: a lamp body wiring device, a lamp holder installing device, an electrical board installing device, a wire management device, a wire bending and pressing device, a lamp holder and outer sleeve integrating device, an adhesive coating device, a light source board assembling device, a circuit welding device and a lampshade assembling device. Performing automated design on various processes greatly saves the cost of human resources and enhances the production efficiency.

Owner:AD TOYO LIGHTING GUANGZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com