a gluing mechanism

A gluing and dispensing machine technology, applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems such as failure to achieve uniform gluing, improve production and operation efficiency, simple structure and realization of functions, Effect of saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

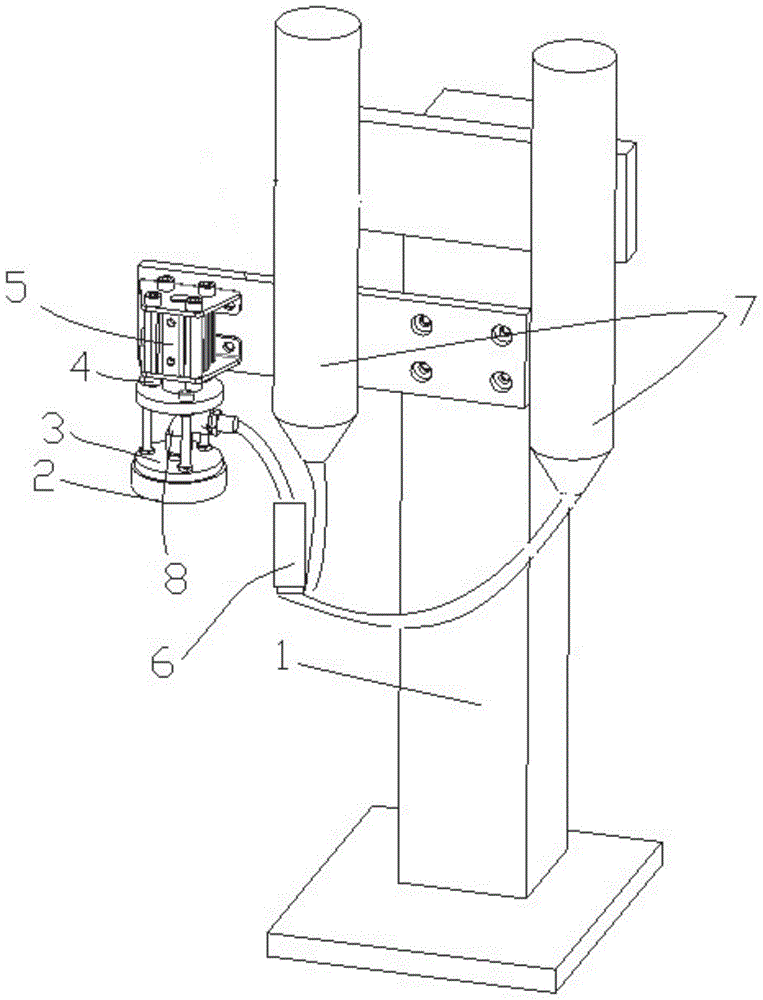

[0035] refer to figure 1 , is an embodiment of the gluing mechanism of the present invention.

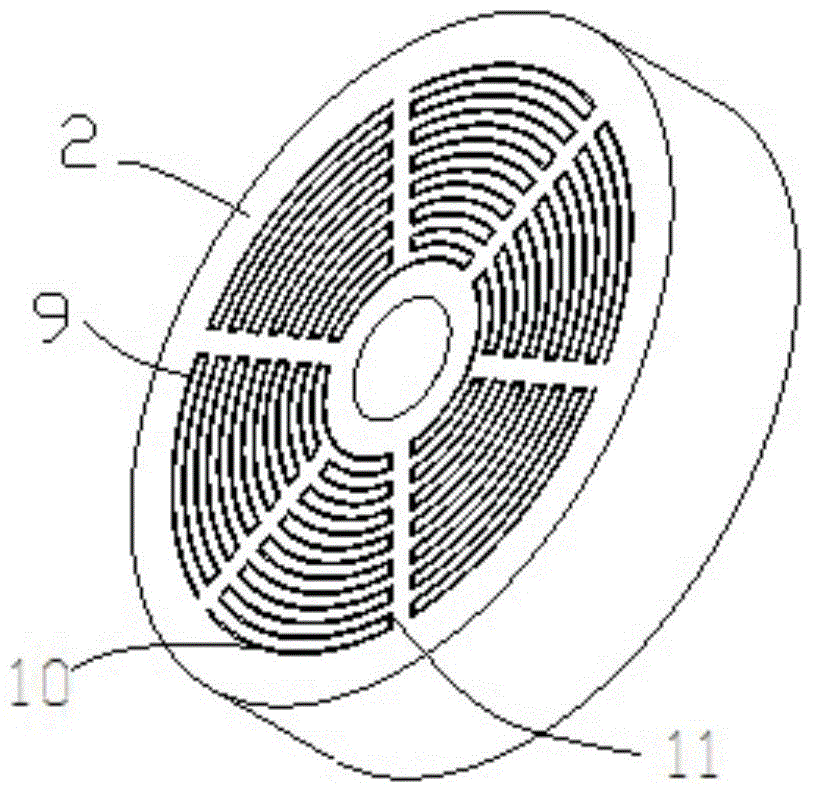

[0036] A gluing mechanism, including a glue dispensing machine, also includes: a bracket 1, a glue delivery cylinder 7, a one-way valve 6, a joint 8, a cylinder 5, a connecting bracket 4, a sleeve plate 3 and a gluing panel 2; wherein:

[0037] Bracket 1 is used for fixing and installing mechanism components.

[0038] The rubber tube 7 is used for storing the glue; the rubber tube 7 is installed on the bracket, the upper end of the rubber tube 7 is an input end, and the lower end is an output end.

[0039] The glue dispensing machine (not shown) is used to control the output volume of the glue liquid;

[0040] The one-way valve 6 is used to limit the flow direction of the glue solution and prevent the backflow of the glue solution;

[0041] The joint 8 is used for pipeline connection; the joint 8 is installed on the cover plate.

[0042] The cylinder 5 is used to drive the gluin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com