Pin inserting mechanism and pin inserting method for inserting four different mould pins into pin terminals

A pin terminal and pin technology, which is applied in the assembly/disassembly of contacts, manufacturing of contacts, etc., can solve the problems of low operation efficiency, difficulty in efficiency and quality control, and difficulty in effectively reducing labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

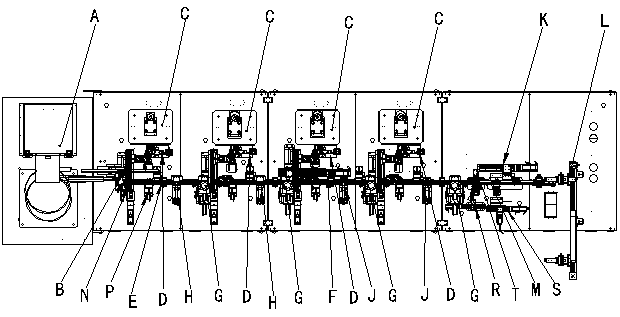

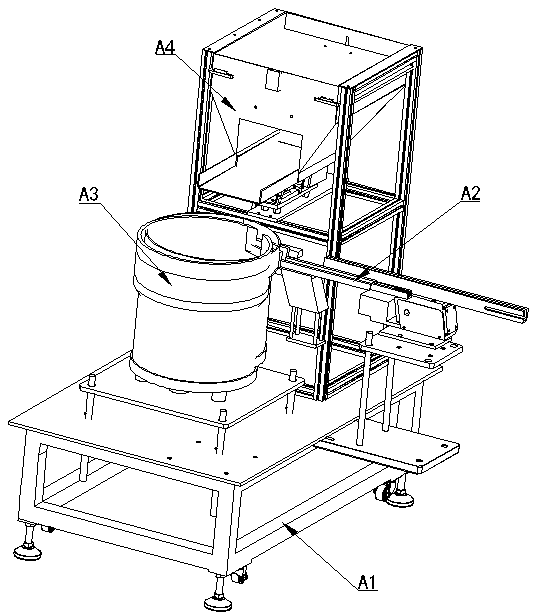

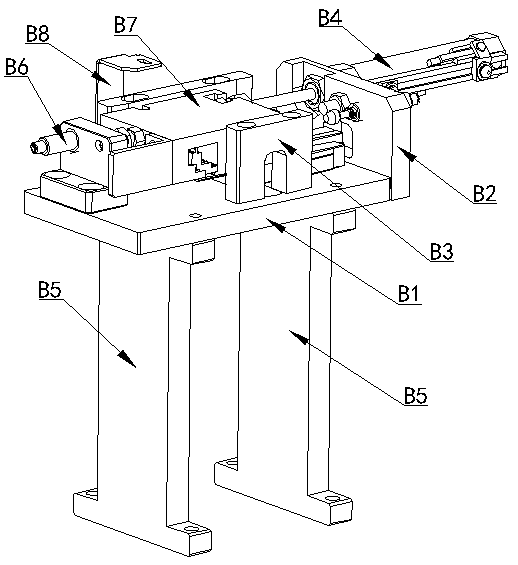

[0053] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 In the shown embodiment, a pin insertion mechanism for inserting four different die pins into the pin terminals includes a main conveying line, a feeding mechanism A, a first material shifting mechanism B, and four different mold materials for forming die pins Forming mechanism C, continuous material cutting mechanism D, material transfer pin assembly N, positioning mechanism P, transfer mechanism E, second material shifting mechanism F, pressing mechanism, material cutting mechanism G, high and low needle detection device R, visual inspection Device S, high and low needle detection and visual detection device T, discharge transfer mechanism K and unloading mechanism L, the first shifting mechanism B is connected with the feeding mechan...

Embodiment 2

[0055] A pin insertion method for inserting four different die pins into a pin terminal, comprising the following steps

[0056] a. Generally, the feeding mechanism in Embodiment 1 sends the pin terminals to the pin terminal feeding step of the first material shifting mechanism described in one of claims 1 to 9;

[0057] b. Feed the entire mold straight pin from the back of the first molding needle mold material forming mechanism in the four different molding needle mold material forming mechanisms of embodiment 1 into the first forming mold needle mold material forming mechanism, hydraulic pressure The first mold pin forming step in which the booster cylinder is pressed down;

[0058] c. After the first type of mold pin is pressed and formed, continue to feed the material forward, and transport the formed first type of mold pin to the continuous material cutting mechanism of Example 1, and the cutting knife takes the first type of mold pin material Cut off the separate conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com