A mechanical turning hand

A technology of mechanical flipping and mechanical arm, applied in the field of mechanical flipping hand, can solve the problems of wasting human resources cost, lack of versatility, inability to carry, etc., and achieve the effects of improving production operation efficiency, strong practicability and versatility, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

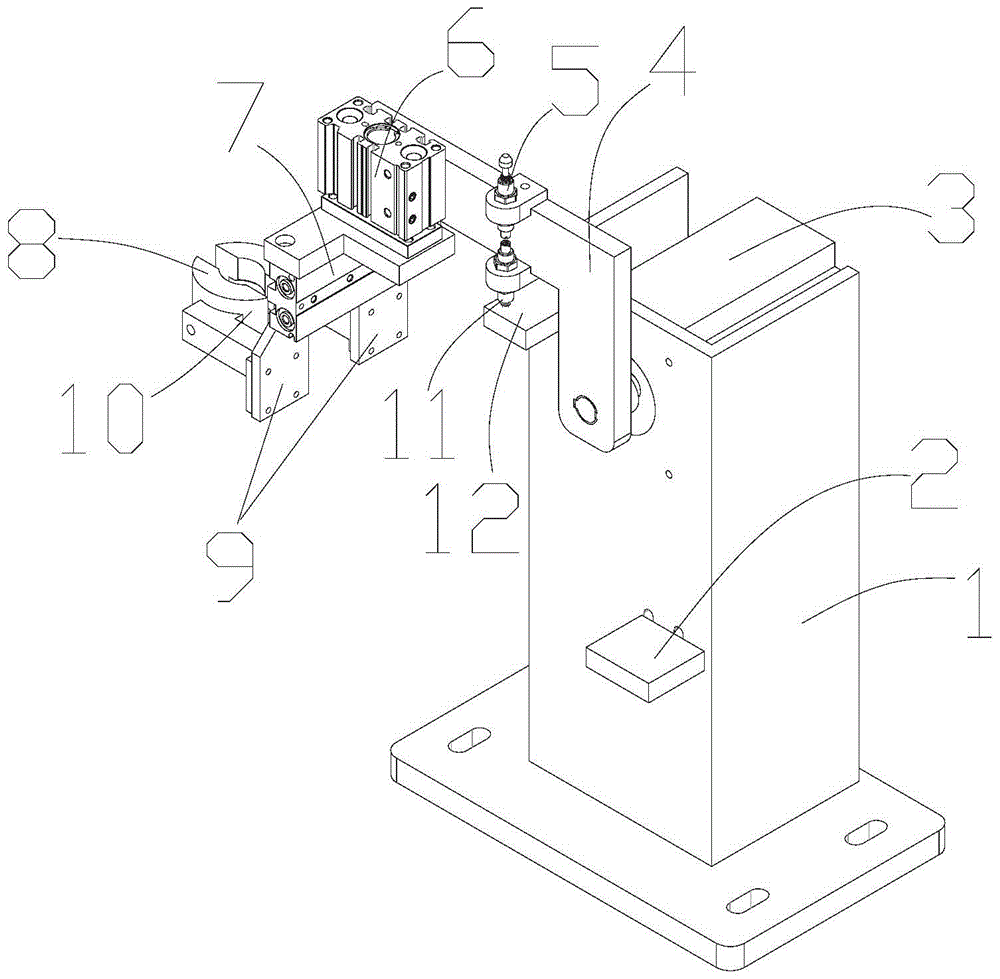

[0030] see figure 1 , is an embodiment of the mechanical turning hand of the present invention.

[0031] In this embodiment, the mechanical turning hand includes: a support 1 , a mechanical arm 4 , a motor 3 , an adjusting cylinder 6 and a gripping device.

[0032] The bracket 1 is used to install the motor 3 .

[0033] The motor 3 is fixed on the bracket 1; the motor 3 is used to drive the mechanical arm 4 to rotate.

[0034] One end of the mechanical arm 4 is mounted on the motor 3 in rotation, and this end is called a fixed end. The other end of the mechanical arm 4 is equipped with an adjustment cylinder 6, and the other end is called a floating end; the mechanical arm 4 is used for installing the adjustment cylinder 6 .

[0035] The gripper 10 device is fixed on the adjustment cylinder 6, specifically on the piston push rod of the adjustment cylinder 6; the gripper 10 is used for grabbing workpieces or products.

[0036] As preferably, the gripping device includes: a g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com