Combination formwork composed of steel bar trusses and bottom die

A technology of reinforced truss and combined formwork, which is applied to floors, building components, building structures, etc., can solve problems such as poor control of steel bar spacing and thickness of concrete protective layer, uneven lower surface of floor slabs, and small clear height of buildings. Achieve the effect of facilitating industrialized assembly line production, improving transportation efficiency and reducing space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

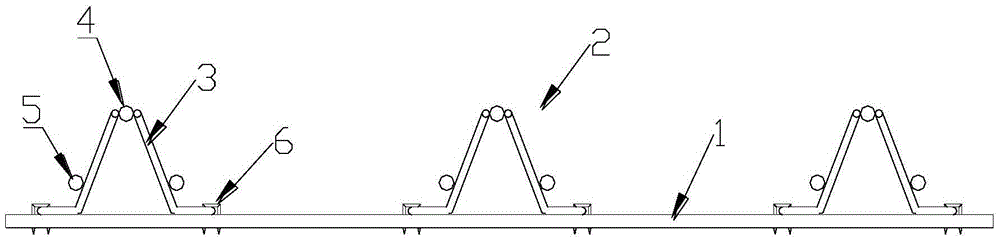

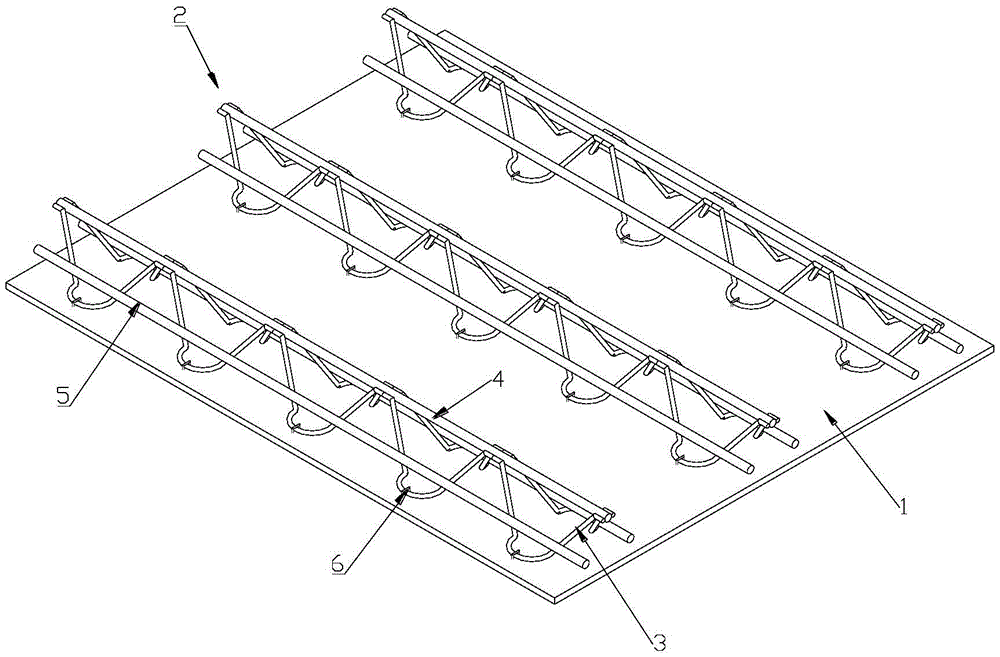

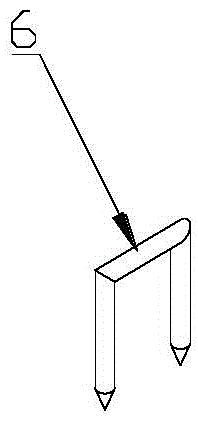

[0023] Such as figure 1 , image 3 Shown, a kind of composite formwork that steel bar truss and bottom form constitute, it comprises steel bar truss 2, tie bars 6 such as saddle nails etc. , Bottom rib 5. The web bars 3 of the steel truss and the bottom non-metal base form 1 are connected as a whole by tie bars such as saddle nails 6. If necessary, they can also be connected to the bottom bars 5 of the steel truss to form other non-metallic truss panels such as reinforced truss pressure cement boards or wood boards. Metal plate floor slab system; or the bottom formwork can also be lifted off by contact with a crowbar; moreover, if wooden formwo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com