Varnish baking device adopting high-frequency heating manner

A high-frequency heating and paint-baking technology, which is applied in the field of paint-baking devices, can solve problems such as difficult hairpin painting and heating baking treatment, affecting the stability of clip body painting, increasing labor force, etc., to meet the needs of use and automation of production machines, improve The effect of production operation efficiency and manpower saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

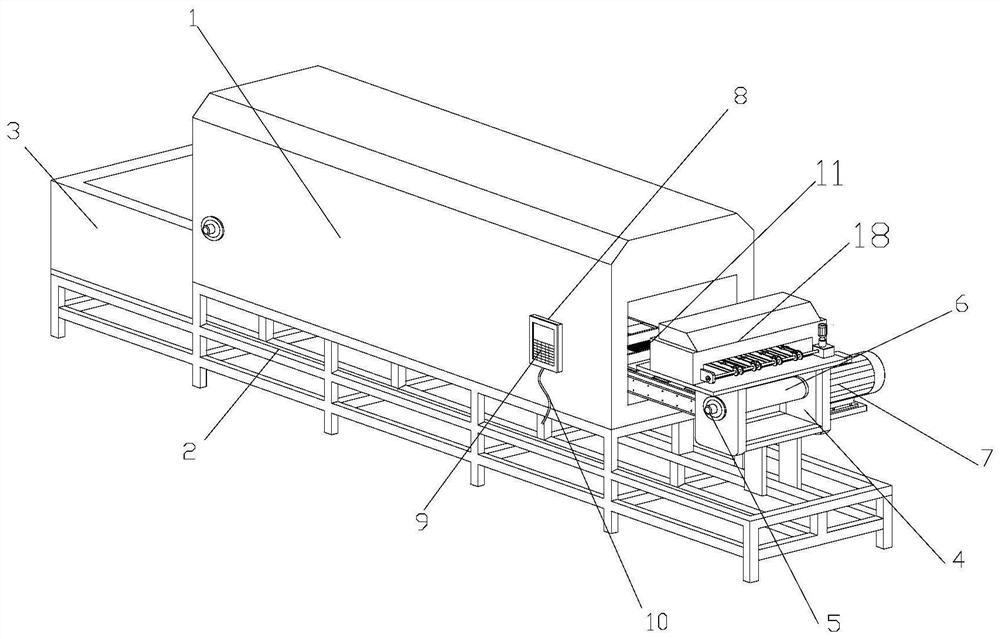

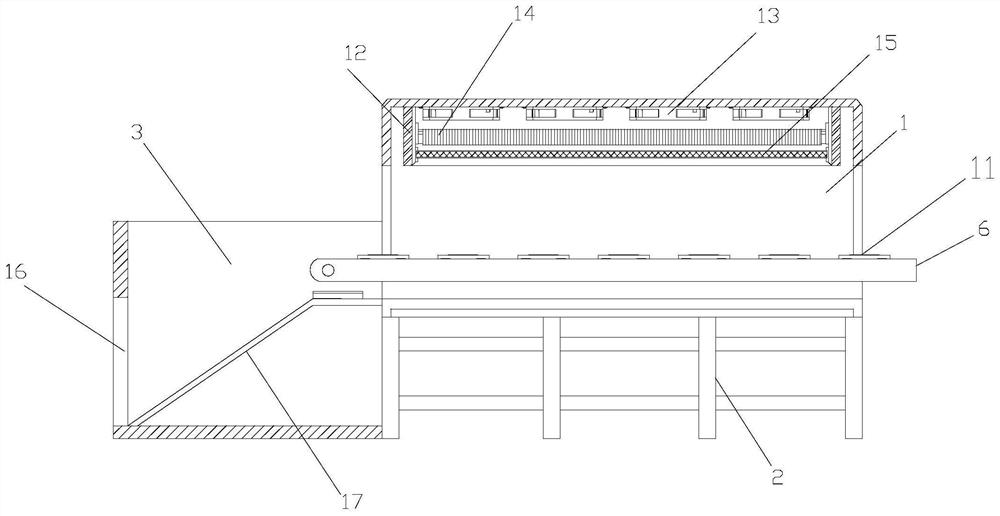

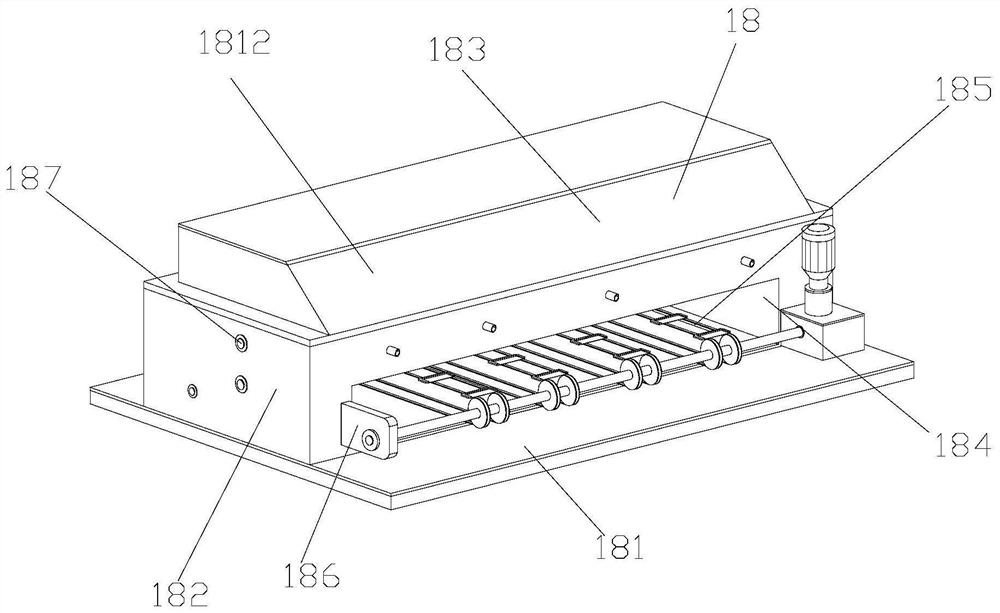

[0030] see Figure 1-9 , the present invention provides a paint baking device using high-frequency heating through improvement, including a baking chamber 1, a bottom frame 2, a waiting tank 3, a support frame 4, a rotating shaft 5, a transmission belt 6, a first motor 7, and an electric control panel 8. Control key 9, power cord 10, positioning plate 11, inner frame 12, fan 13, high-frequency electric heating tube 14, partition 15, outlet 16, inclined plate 17 and shifting assembly 18, the bottom of the baking chamber 1 The bottom frame 2 is welded, the right end of the waiting tank 3 is welded to the grill bin 1, the bolts at the bottom end of the bracket 4 are installed on the bottom frame 2, and the front and rear ends of the rotating shaft 5 are rotated and installed on the grill bin 1 and the bracket 4, the outer wall of the rotating shaft 5 is equipped with a transmission belt 6, and the rear end of the rotating shaft 5 passes through the bracket 4 and is fixed with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com