Low temperature pump cold screen

A technology of cryogenic pump and cryogenic refrigerator, applied in the direction of pumps, pump components, variable capacity pump components, etc., can solve the problems of small condensation area, low capture efficiency, easy rebound of gas molecules, etc., to improve the pumping speed, The effect of increasing pumping speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

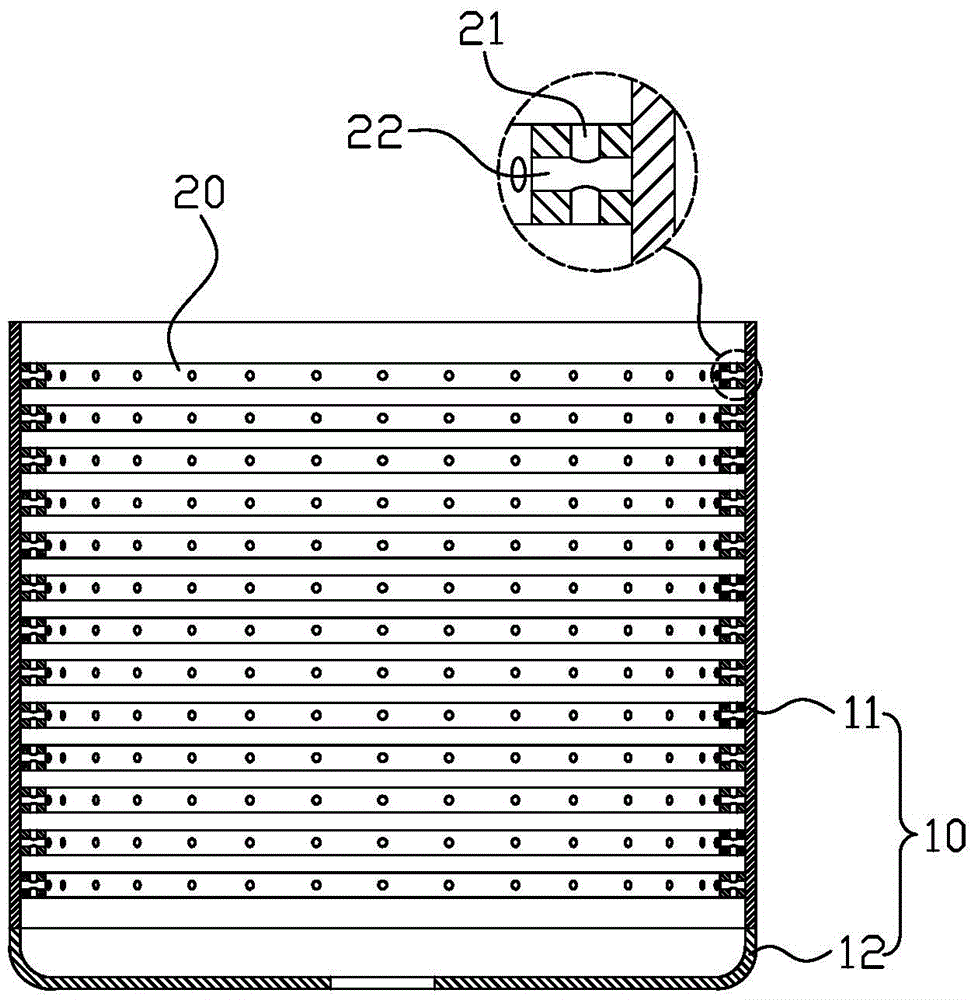

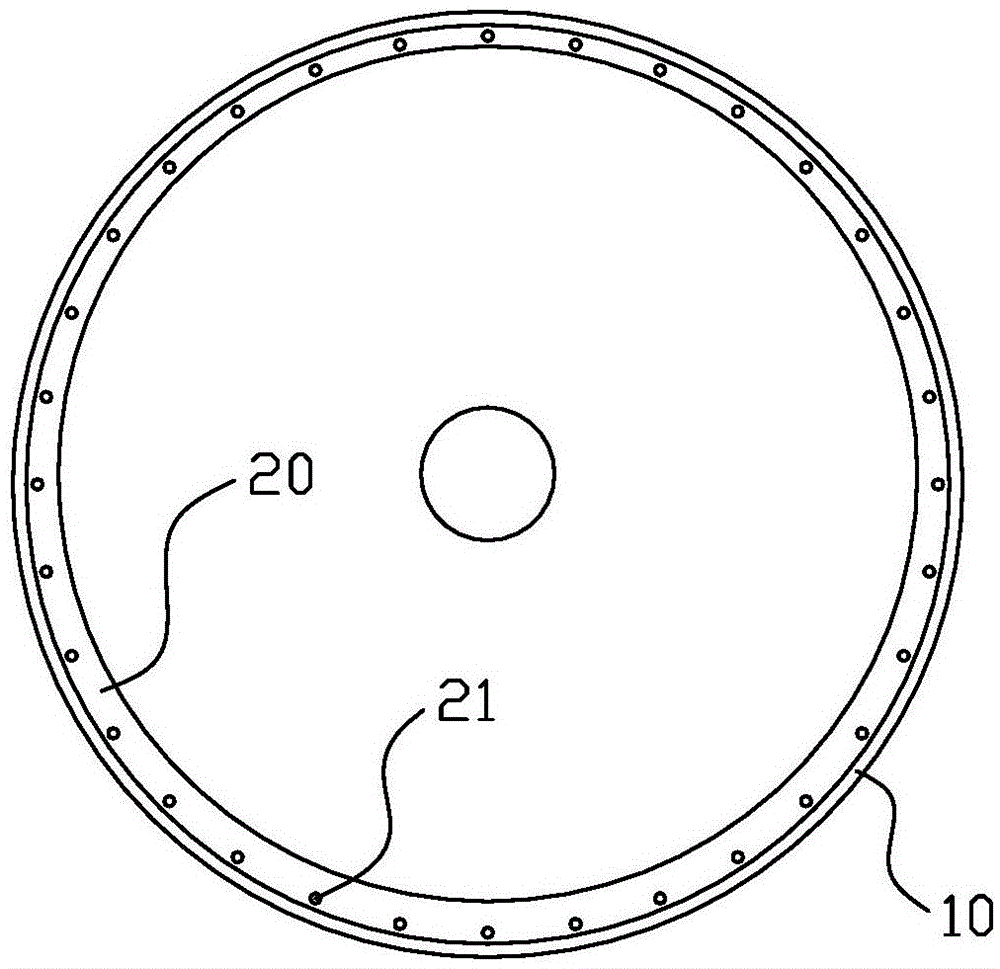

[0023] Embodiment one: if figure 1 , 2 As shown, the protrusions are arranged on the barrel wall of the cold screen body 10. The protrusions are in the shape of thin sheets or slats. The section of the protrusions along the axial direction of the cold screen body 10 is fan-shaped or ring-shaped. The center of the circle is located on the axis line of the cold screen body 10 . The sector mentioned here is a part of the ring. The fan-shaped or ring-shaped protrusions are convenient to arrange, and are evenly arranged on the barrel wall of the cold shield body 10, so that the condensation of the gas is more uniform. In addition, the fan-shaped or ring-shaped protrusions have the same protrusion height relative to the cold screen body 10 , and will not interfere with other components provided on the cold screen body 10 .

[0024] Specifically, the protrusions are annular plate-shaped first ribs 20 , and a plurality of first ribs 20 are evenly spaced along the axial direction of...

Embodiment 2

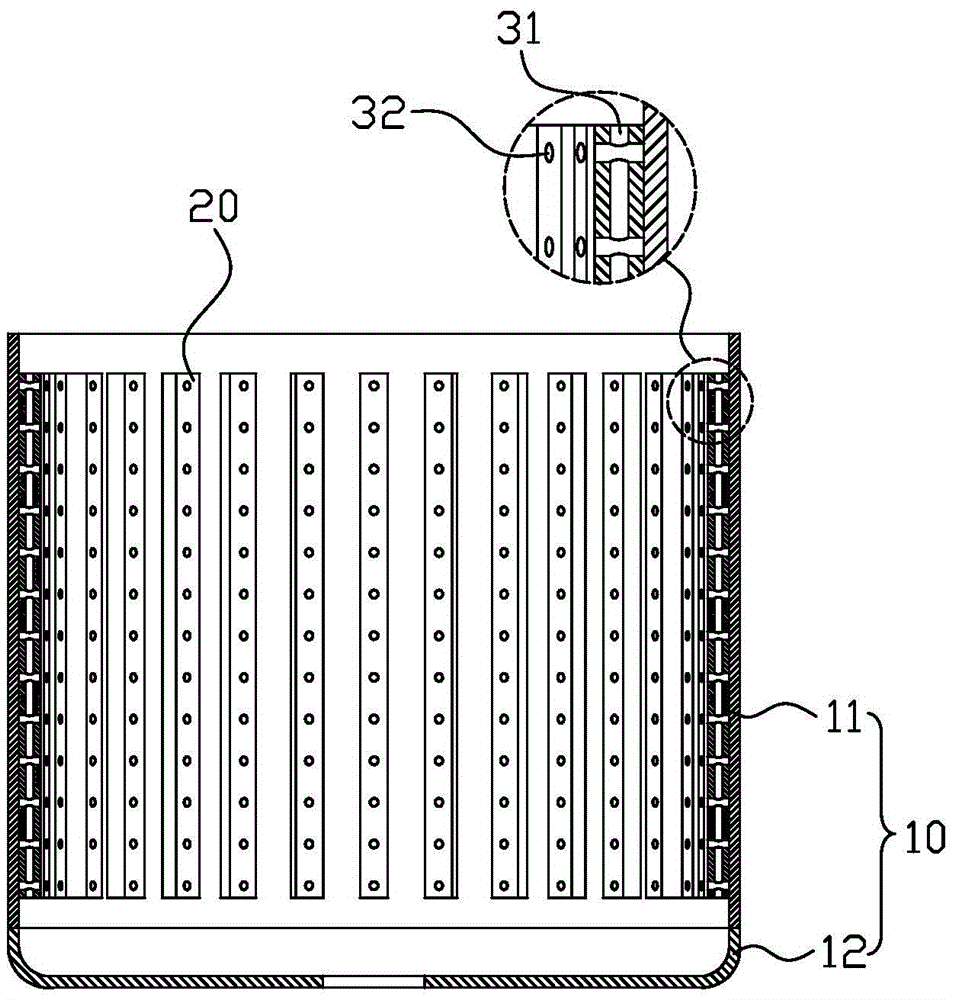

[0025] Example two such as image 3 , Figure 4 As shown, the protrusions are arranged on the barrel wall of the cold shield body 10 , the protrusions are in the shape of rectangular sheets or slats, and the length direction of the protrusions is parallel to the axial direction of the cold shield body 10 . The difference from Embodiment 1 is that the protrusions are rectangular instead of annular. Although the structures are different, they all have the same effect.

[0026] Specifically, the protrusion is a second rib 30 in the shape of a rectangular plate, and a plurality of second ribs 30 are evenly spaced along the circumferential direction; a third through hole 31 and a plurality of second ribs 30 are opened on the second rib 30 Four through holes 32, the axis direction of the third through hole 31 is parallel to the axis direction of the cold shield body 10, the axis direction of the fourth through hole 32 is arranged along the radial direction of the cold shield body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com