Clamp for clamping electronic component

A technology of electronic components and fixtures, which is applied in the field of clamps for clamping electronic components, and can solve the problems of insufficient clamping force, small size tolerance of power transistors, and limited clamping area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

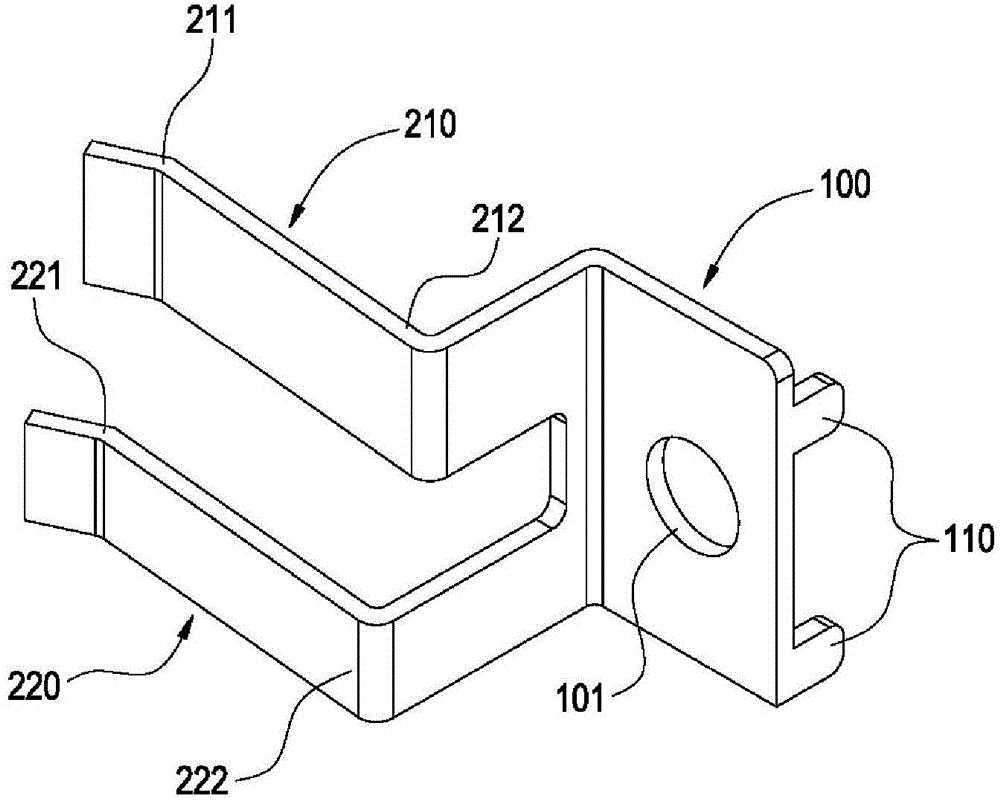

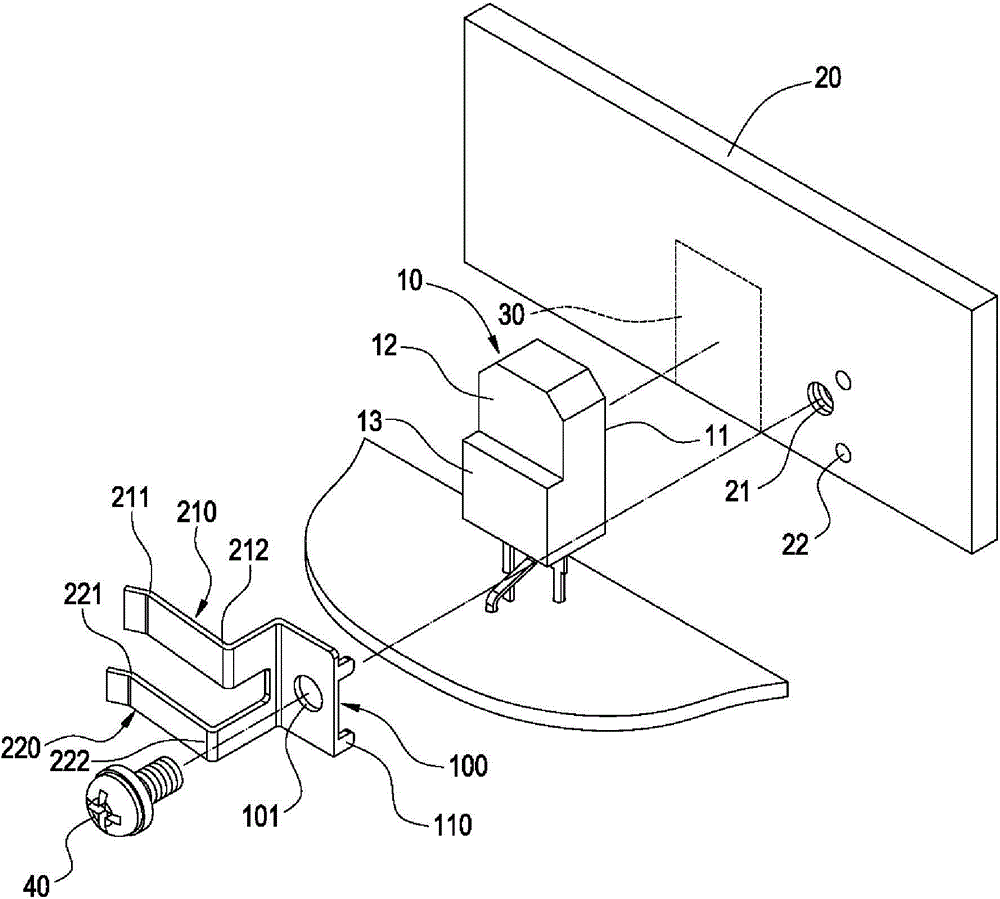

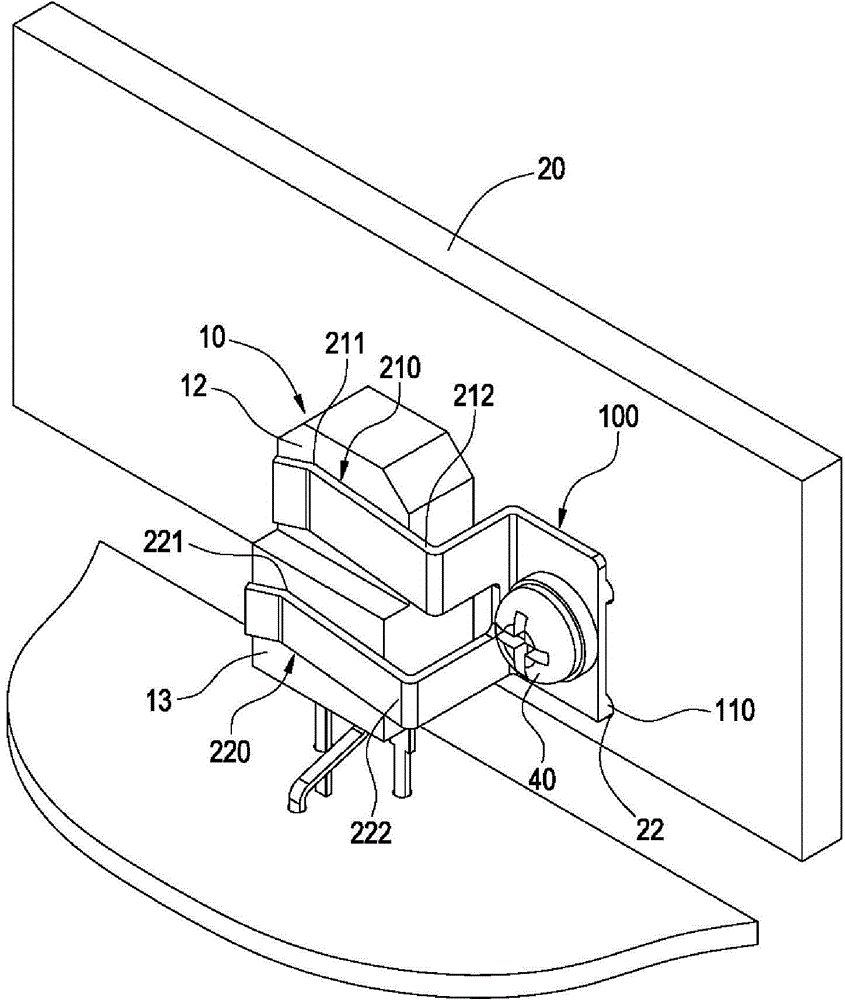

[0038] See Figure 1 to Figure 3 The first embodiment of the present invention provides a clamp for clamping electronic components, which is used to clamp and attach an electronic component 10 to a heat sink 20, which includes a body 100 and a plurality of clamping jaws 210 / 220 .

[0039] In this embodiment, the main body 100 is preferably a rectangular sheet metal body, the main body 100 is provided with a through hole 101, and a plurality of positioning pins 110 are preferably extended from an edge of the main body 100, and each positioning pin 110 is bent. Vertical body 100.

[0040] In this embodiment, the other edge of the main body 100 extends two clamping jaws 210 / 220 arranged opposite to the positioning pins 110, but the present invention does not limit the number of clamping jaws 210 / 220. Each clamping jaw 210 / 220 is a bent long metal sheet, and the two clamping jaws 210 / 220 are arranged parallel to each other. The ends of each clamping jaw 210 / 220 are bent to form a cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com