Cage leaf spring and socket and electrical connector using the leaf spring

A technology of cage type and leaf spring, which is applied in the field of cage type leaf spring and jacks and electrical connectors using the leaf spring, which can solve the problems of complicated operation of connecting wire spring strips, and achieve the effect of simple and convenient forming process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

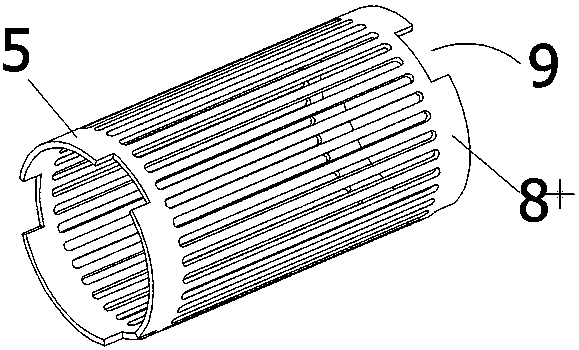

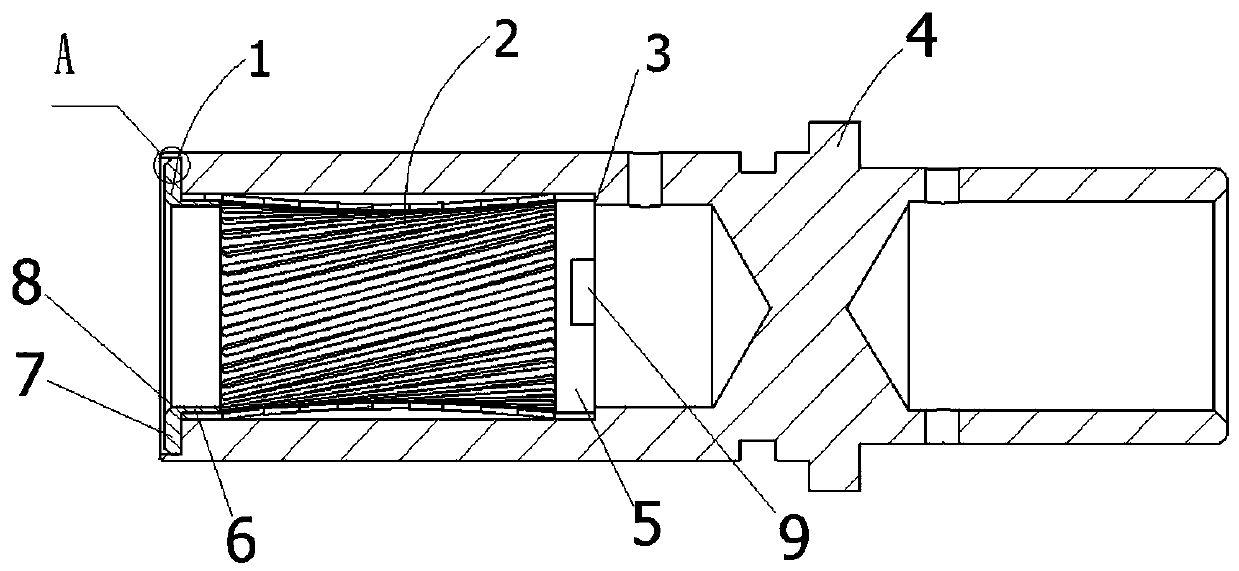

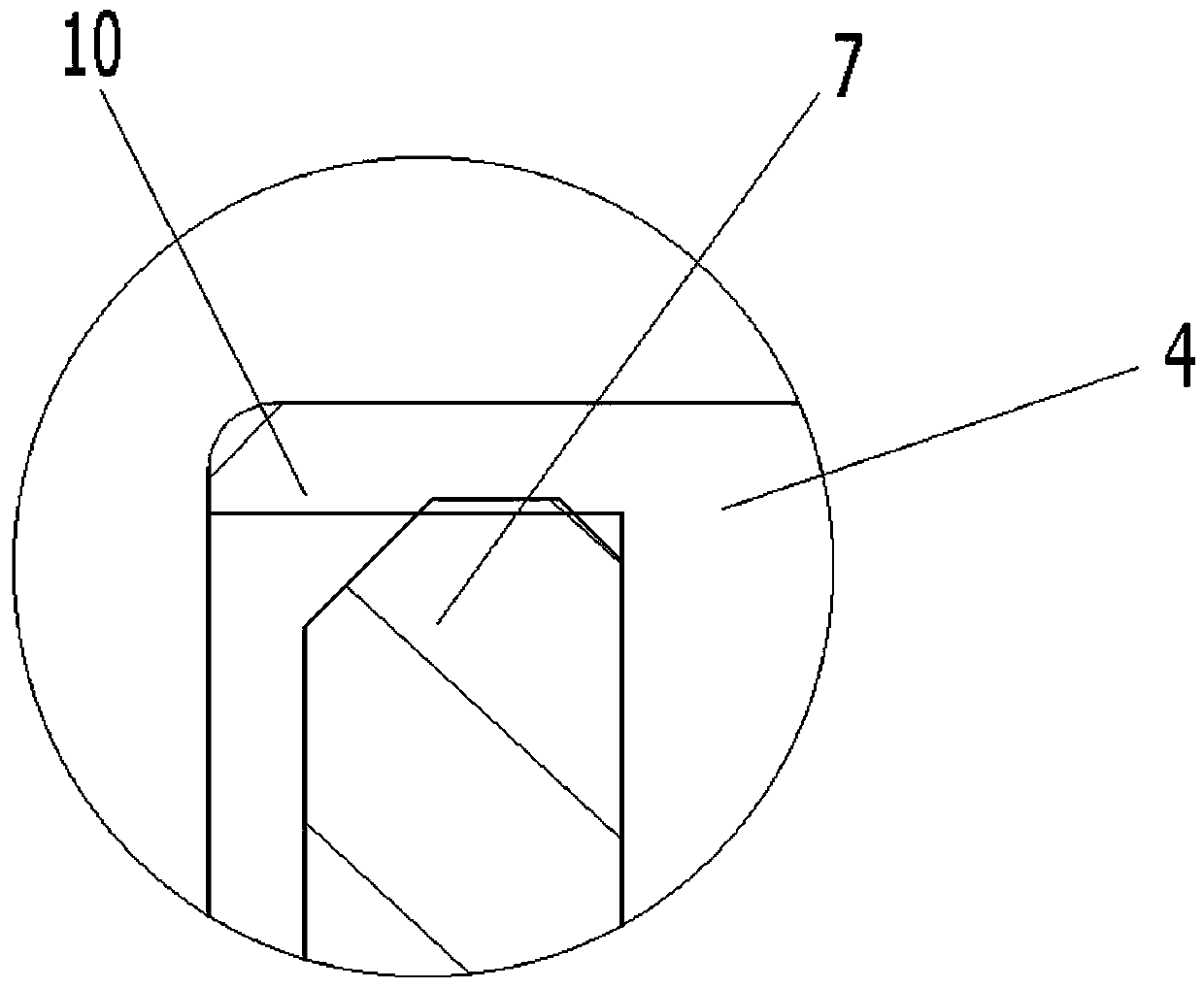

[0026] Examples of electrical connectors are Figure 1~3 Shown: including the housing (not shown in the figure) and the socket provided on the housing, the housing belongs to the prior art, and its structure is not believed to be described here. The jack includes a rear cover 4 and a cage leaf spring 2 fixed in the inner hole of the rear cover through a fixed structure. The cage leaf spring 2 is integrally arranged between the front and rear end rings by the front ring 8 and the rear end ring 5. The connecting wire spring bar 11 is composed of the connecting wire spring bar 11. The connecting line spring bar 11 is a hyperboloid structure whose extension direction intersects the axis space of the front and rear end rings and is inclined in the same direction relative to the axes of the front and rear end rings. The front and rear end rings The inner holes of the corresponding torsion fixtures are respectively adapted and inserted in the front and rear directions. The front and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com