A mandarin duck hot pot with electric lifting structure

A technology of lifting structure and hot pot, which is applied in household utensils, kitchen utensils, and multi-unit cooking utensils. Cooking time, easy to pick, avoid the effect of sticking the pot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

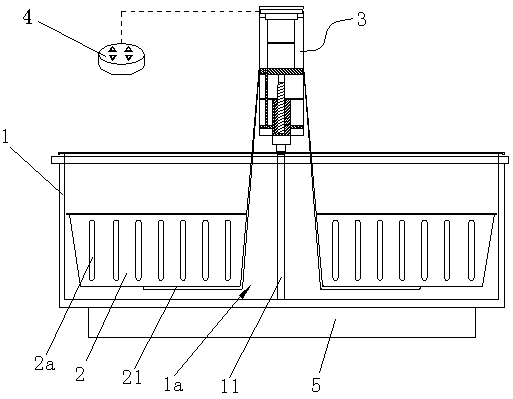

[0038] Embodiment one, such as Figure 1 to Figure 5 as shown,

[0039] A mandarin duck hot pot with an electric lifting structure, comprising an outer pot body 1, a partition 11 is arranged in the middle of the outer pot body 1 to form two hot pot cavities 1a, an inner pot body 2 is respectively arranged in the hot pot cavity 1a, and the inner pot body The body 2 cooperates with the elevator 3 arranged vertically respectively; Screw rod 37, battery 32, circuit board 33 and motor 34 constitute electric circuit, the output shaft of motor 34 cooperates with screw rod 37 through speed reducer 35, and the lower end of connecting rod 36 is fixed on the described dividing plate 11, and its upper end is connected with A nut 36a matching the shape of the lifter shell 31, the nut 36a is screwed and matched with the screw rod 37, the inner pot body 2 is fixed with the lifter shell 31, and the circuit board 33 is connected to the controller 4 for signal; the controller 4 controls the li...

Embodiment 2

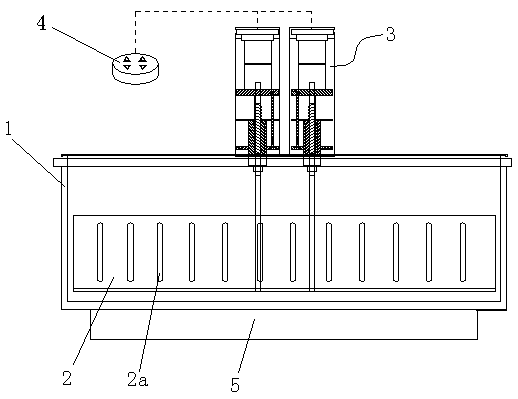

[0060] Embodiment two, such as Figure 6 to Figure 7 as shown,

[0061] The mandarin duck hotpot in this embodiment is similar to the structure in Embodiment 1, the difference is that in this embodiment, the lifter casing 31 is a prismatic structure, and correspondingly, the nut 36a is a polygonal structure, and the nut 36a is snap-fit in the lifter housing 31.

[0062] Since the nut 36a in this embodiment has a polygonal structure and the lifter housing 31 has a prismatic structure, the nut 36a cannot rotate when it is stuck in the lifter housing 31 , so the structure of the guide post 38 is omitted.

[0063] Working principle: the controller 4 controls the forward rotation and reverse rotation of the motor 34. The rotation of the motor 34 drives the screw 37 to rotate. Since the nut 36a is stuck in the lifter shell 31 and cannot rotate, the rotation of the screw 37 is realized by generating a reaction force on the nut 36a. The rise and fall of the screw rod 37. The liftin...

Embodiment 3

[0064] Embodiment three, such as Figure 8 to Figure 10 as shown,

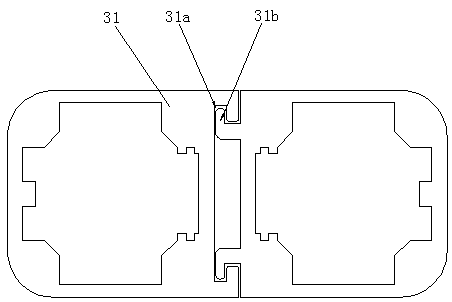

[0065] The mandarin duck hotpot in this embodiment is similar to the structure in Embodiment 1, the difference is that in this embodiment, the lifter housing 31 is a prismatic structure, the nut 36a is a circular structure, and the nut 36a is provided with a bump, The protrusion matches with the guide post 38 fixed in the housing 31 of the lifter. The two lifter shells 31 are connected by snap-fit structure, one lifter shell 31 is provided with a chute 31a, and the other lifter shell 31 is provided with a slide block 31b matching the chute 31a, and the slide block 31b Placed in the chute 31a. Relative movement is formed between the slider 31b and the chute 31a, which will not affect the lifting of any lifter casing 31 . The two lifter housings 31 connected by this structure are more compact in structure and more beautiful in appearance.

[0066] Working principle: the controller 4 controls the forward ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com