An automatic pre-inspection device for hydraulic engineering lifting

A water conservancy project and maintenance device technology, applied in building maintenance, construction, scaffolding accessories, etc., can solve the problems of increasing the risk factor of workers, inconvenient removal of decorative panels, and damage of decorative panels, so as to improve safety factor and facilitate hammering The position of the click device, the effect of convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

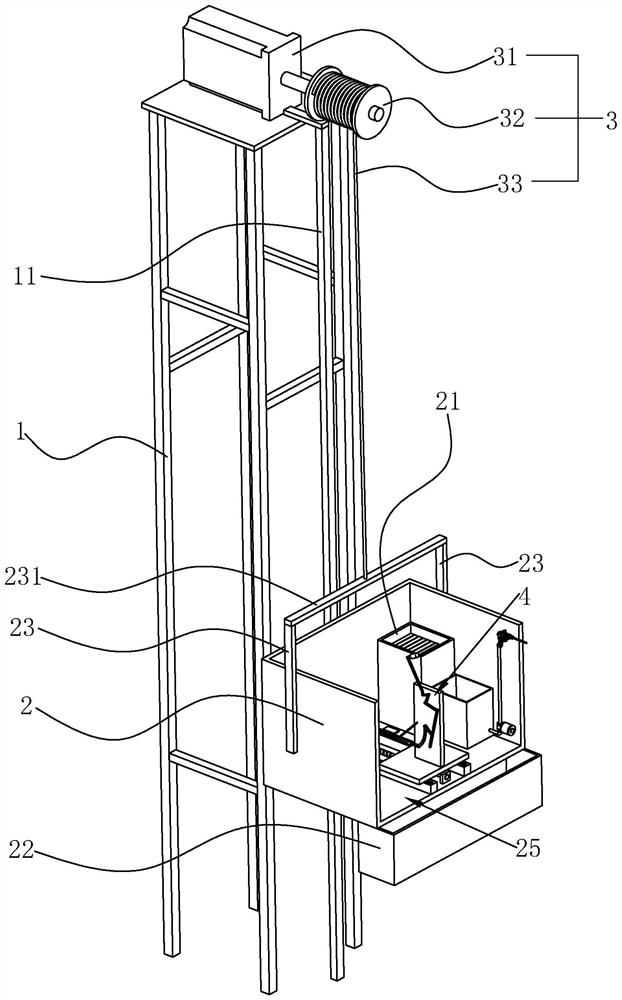

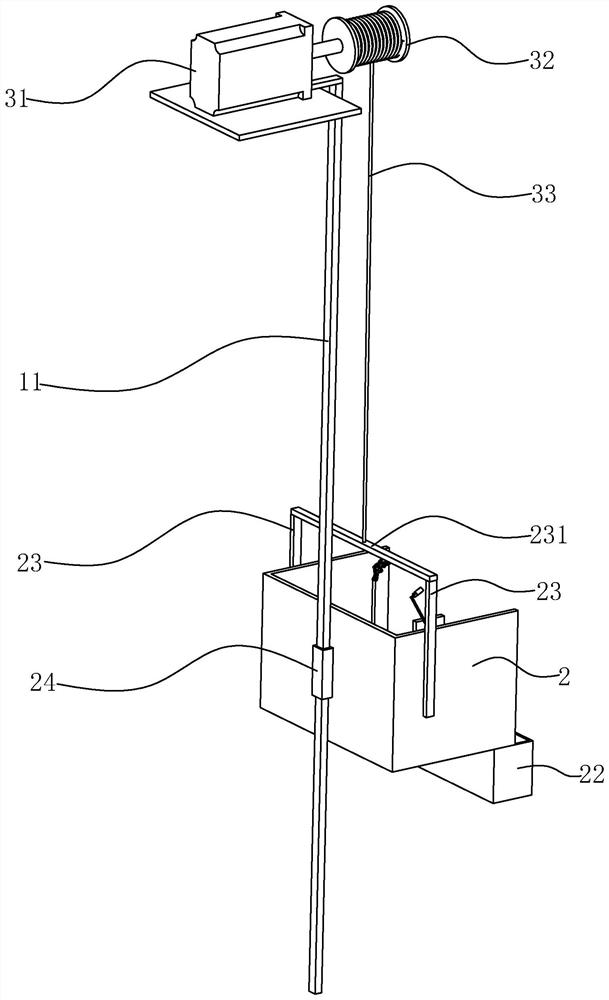

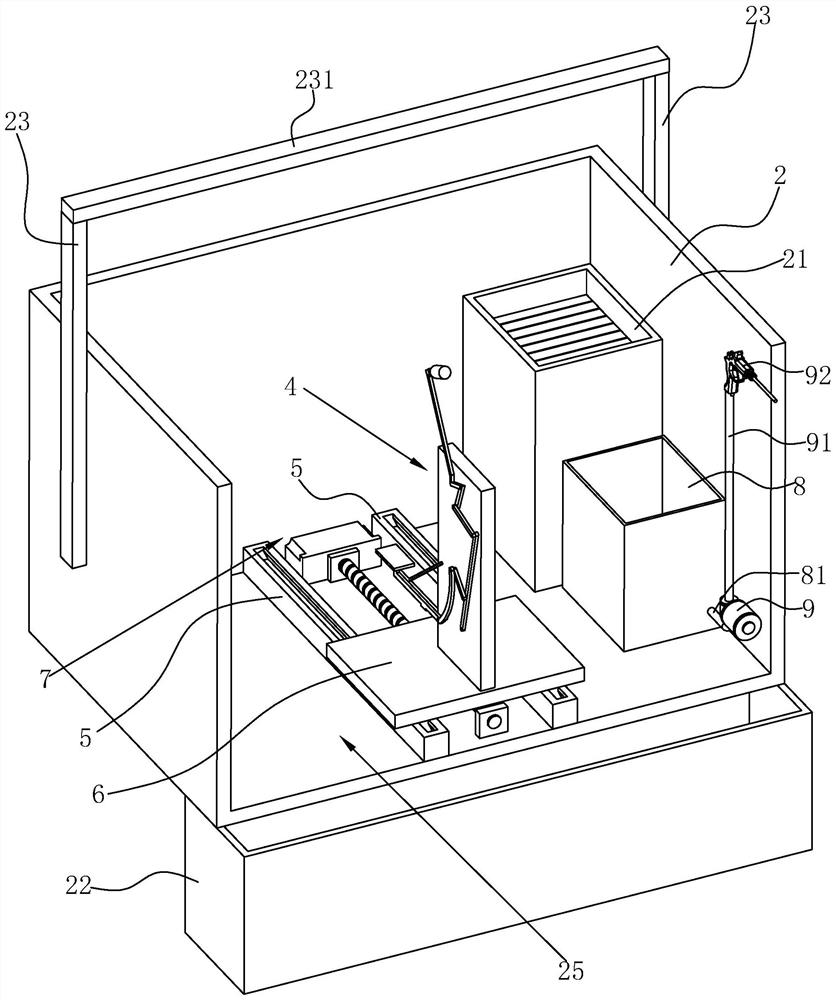

[0035] refer to figure 1 , figure 2 , is a hydraulic engineering lifting automatic pre-overhaul device disclosed in the present invention, including a support frame 1, and an inspection box 2 is installed on the support frame 1 to move vertically. The upper part of the inspection box 2 is opened and the interior is hollow. There is a lifting assembly 3, and the lifting assembly 3 is used to drive the maintenance box 2 to lift in the vertical direction; specifically, the lifting assembly 3 includes a servo motor 31, a winding wheel 32 and a traction rope 33, and the servo motor 31 is arranged on the support frame 1. At the top, the reel 32 is coaxially arranged on the output shaft of the servo motor 31, the traction rope 33 is wound on the reel 32, and a section of the traction rope 33 extends vertically downwards, on the two side walls of the inspection box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com