Screw feeding device

A supply device and screw technology, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of screw flipping and material jamming, and achieve the effect of improving feeding efficiency and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The implementation of the present invention is described below through specific specific implementation forms. Those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification, and can also be implemented or applied through other different specific implementation forms.

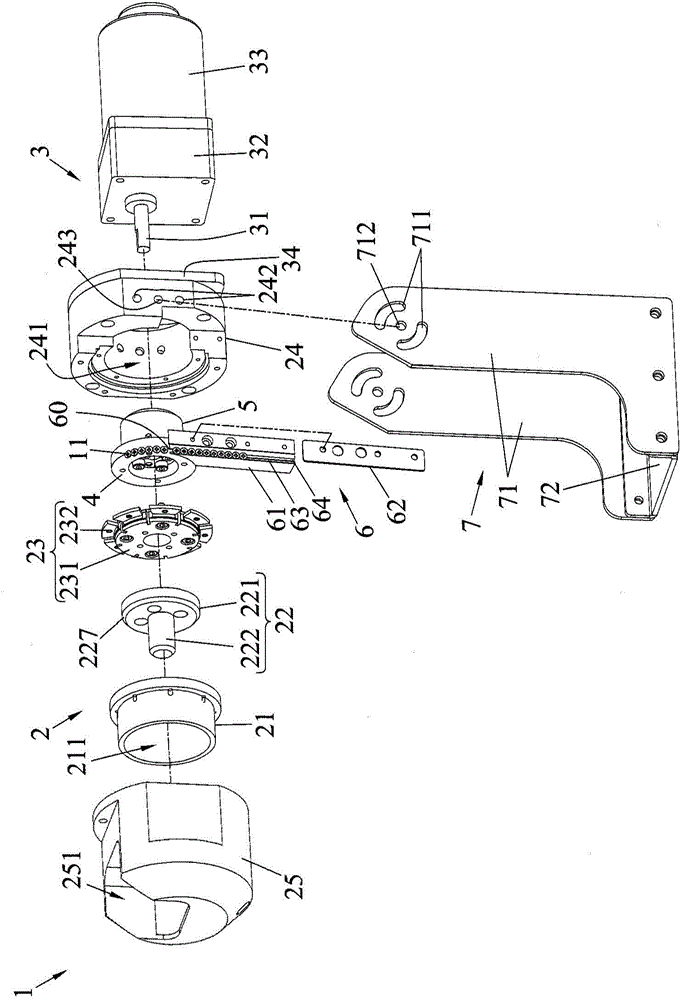

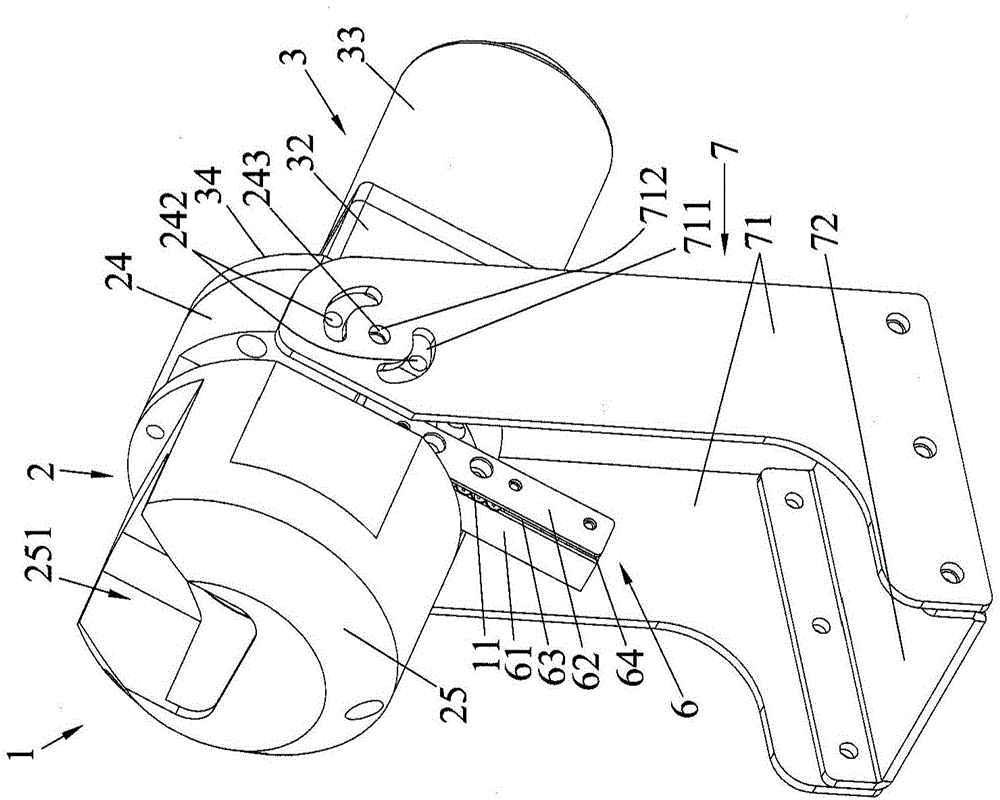

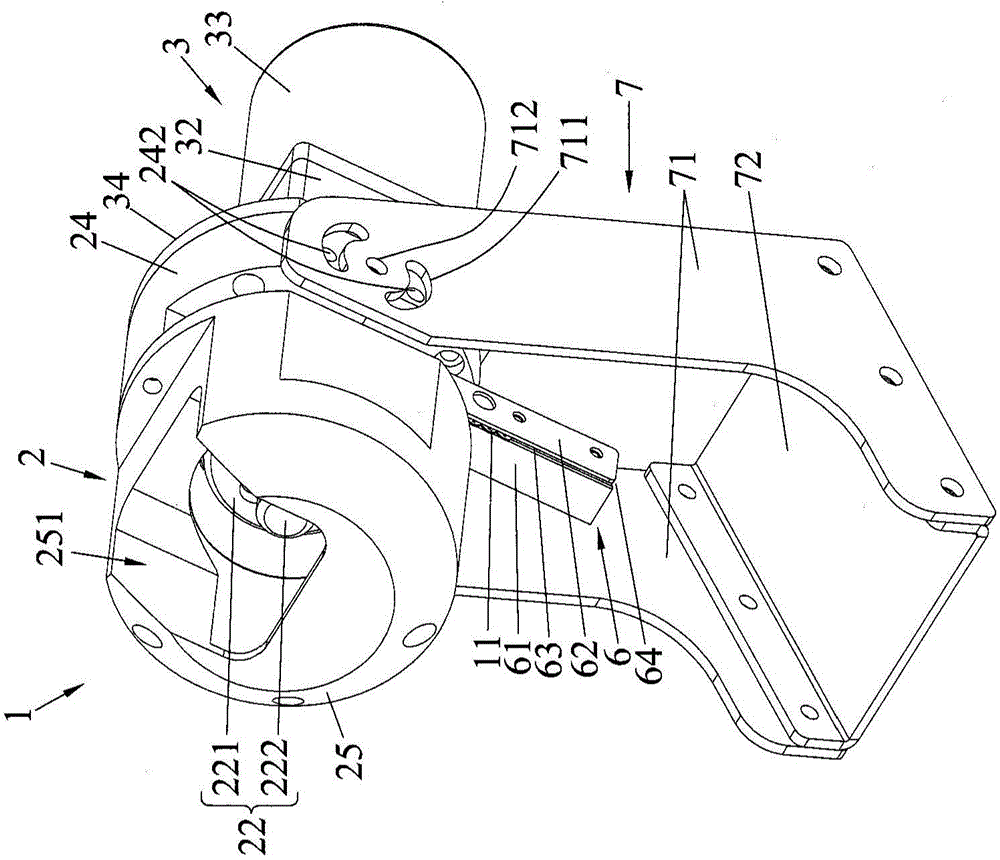

[0082] Figure 1A To illustrate an exploded perspective view of the screw supply device 1 of the present invention, Figure 1B to Figure 1D It is a perspective view showing different combinations of the screw supply device 1 in FIG. 1 of the present invention, wherein, Figure 1D One of the two supporting elements 71 is not shown, Figure 1E The supply housing 25 is not shown.

[0083] Such as Figure 1A to Figure 1E As shown, the screw supply device 1 mainly includes a supply module 2 and a power module 3 .

[0084] The feeding module 2 has a hollow shell 21, a material shifting element 22 and a sieve turntable 23,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com