Installing and debugging technology for hydraulic loading and unloading machines

A technology for installation, commissioning, and loading and unloading, which is applied in the direction of lifting devices, etc., and can solve problems such as singleness, inability to guarantee product quality, and product function requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

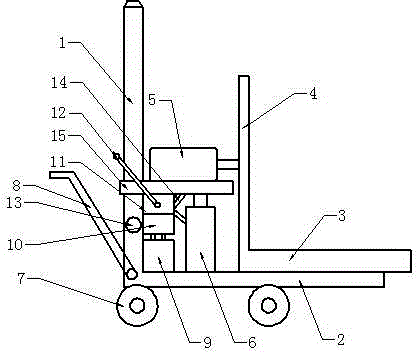

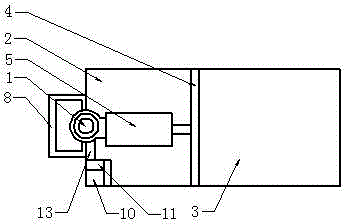

[0009] The present invention will be further described below in conjunction with accompanying drawing.

[0010] In the view, take the hydraulic loading and unloading machine as an example: the sliding center column 1, the manual push rod 8 are installed at the rear end of the base plate 2, the running wheels 7 are installed at the bottom of the base plate 2—the motor 9 and the hydraulic oil tank 10 are installed longitudinally in sequence on the rear part of the upper plane of the base plate 2 1. Hydraulic oil pump 11 with hydraulic handle 12—longitudinal oil cylinder 6, lifting plate 15, and horizontal oil cylinder 5 are installed in sequence before the motor 9—the movable cargo plate 3 with the backrest board 4 fixed is installed on the front part of the upper plane of the bottom plate 2—horizontal The telescopic column of the oil cylinder 5 is rigidly connected to the backboard 4—one end of the hydraulic oil pipe 14 is connected to the hydraulic oil pump 11, and the other en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com