Longitudinal sleeper vibration damping track and its vibration damping assembly

A technology of vibration damping components and sleepers, which is applied in the direction of tracks, roads, fixed rails, etc., can solve the problems of poor vibration damping effect and achieve good vibration damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

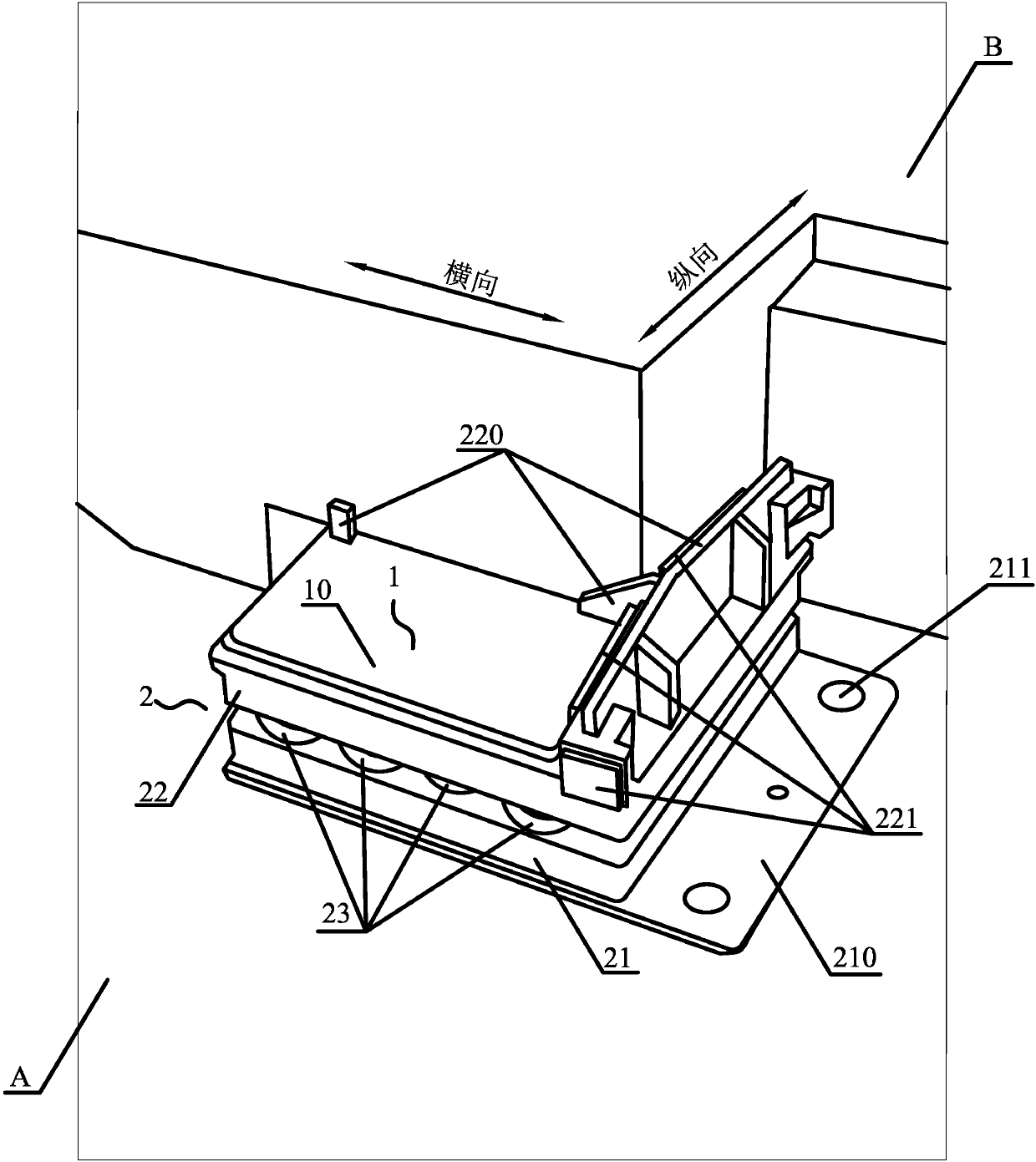

[0066] Referring to Fig. 1 , the vibration damping assembly according to the first embodiment of the present invention has a superimposed first elastic member 1 and a second elastic member 2, and there is a sufficient difference between the elastic forces of the two so that the overall vibration damping assembly is divided into two parts. Stage vibration damping effect (in order to obtain a better vibration damping effect, and at the same time, have higher safety performance and higher durability, preferably the stiffness ratio of the two is between 4.1:5.3 and 3.7:4.4).

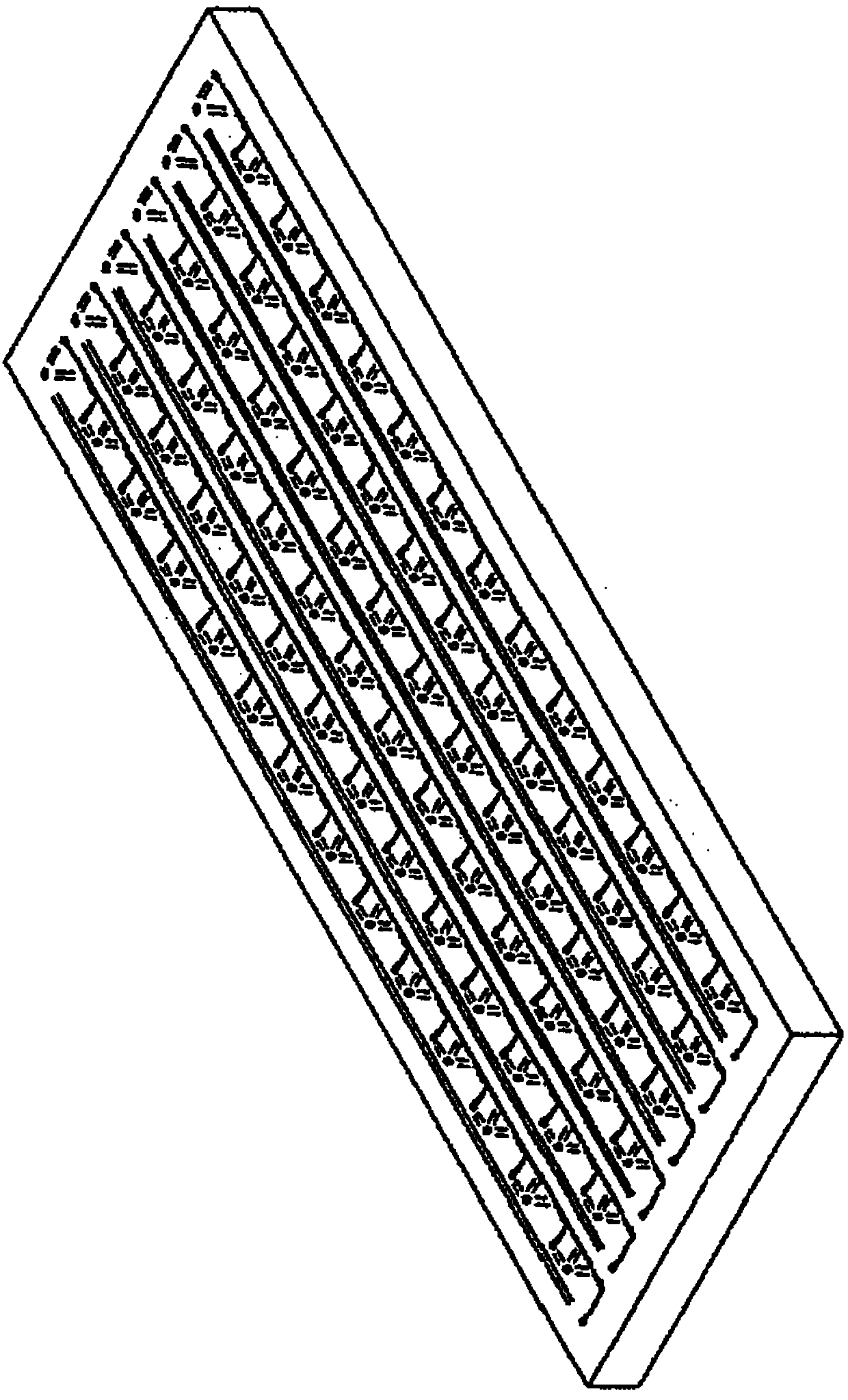

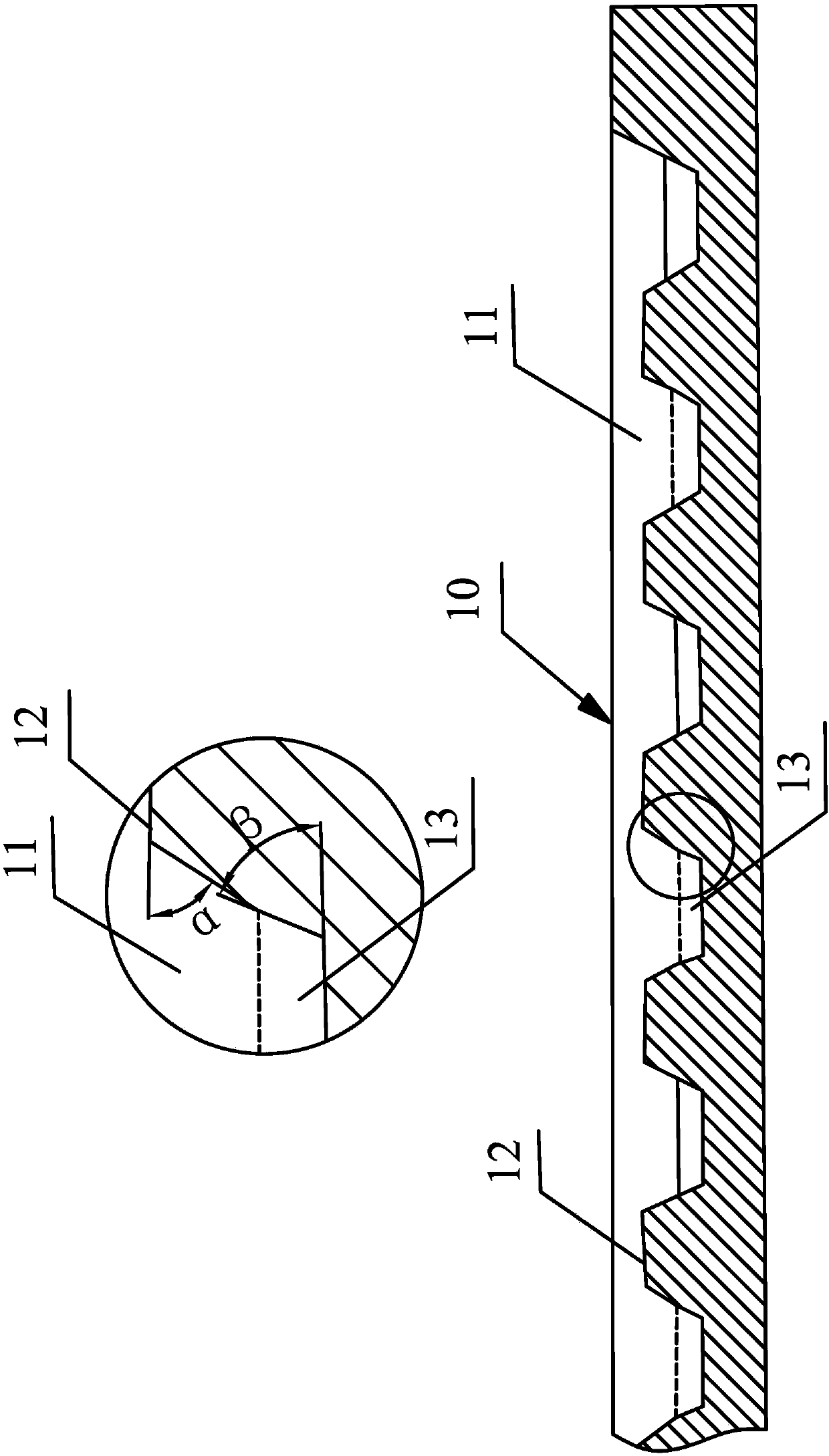

[0067] Wherein, the first elastic member is made of elastic material (such as rubber), and its stiffness can be 18.5±0.3KN / mm 2 ,Such as Figure 1A , Figure 1B As shown, it is plate-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com