Small angle crossing concrete-filled steel tube column internal stiffening tubular joint and making method thereof

A technology of steel pipe concrete columns and intersecting joints, which is applied in the direction of architecture and building construction, can solve problems such as difficulties in joint structure design and construction, failure to meet the requirements of architectural design appearance, etc., and achieve good architectural appearance effects and stress safety Reliable, effect of reducing welding workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

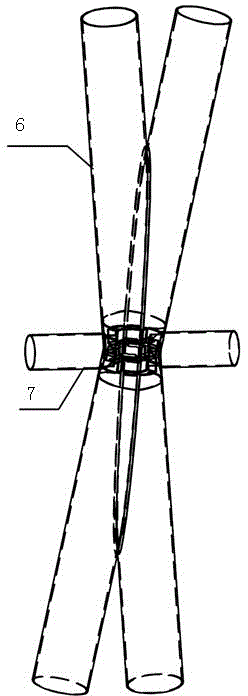

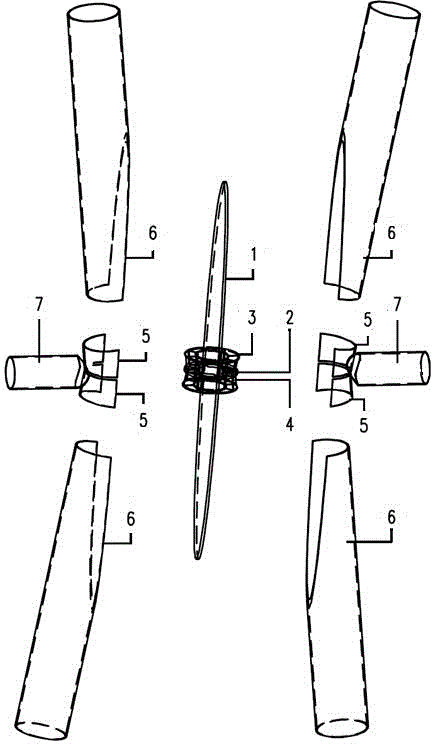

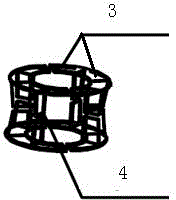

[0027] like figure 1 and figure 2 As shown, a small-angle crossed concrete-filled steel tubular column inner stiffened intersecting node, which includes an elliptical connecting plate 1 and an elliptical connecting plate that are vertically welded together between the intersection points of the crossed CFST columns 6. The annular connecting plate 2 formed by two semi-annular connecting plates respectively connects the left and right sides, the upper half and the lower half of the steel pipe at the intersection together. The steel pipe wall and the steel pipe body of the CFST column at the connection position are It is broken into an arc-shaped plate 5; the upper and lower parts of the annular connecting plate are respectively provided with annular reinforcing plates 3 surrounding the elliptical connecting plate, and vertical Stiffener 4, the arc-shaped plate surrounds the annular connecting plate and is connected to the annular connecting plate, the annular reinforcing plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com