A double-wave inner fin structure intercooler

A technology of internal fins and coolers, applied in the direction of machines/engines, internal combustion piston engines, mechanical equipment, etc., can solve the problems of increasing investment, increasing costs, adding new tooling, molds and new equipment, etc., to improve the structure The effect of strength, structural strength improvement, and overall structural strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

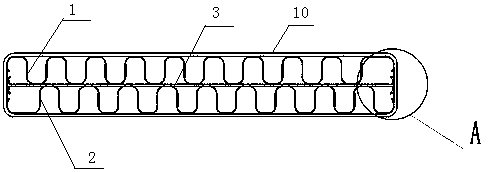

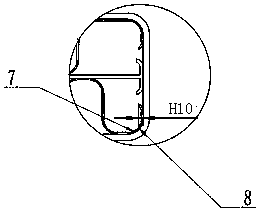

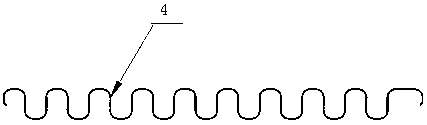

[0024] From Figure 12 It can be seen from the schematic diagram of the overall structure of the present invention that the present invention includes a first end cooling medium storage chamber 21, a second end cooling medium storage chamber 22 corresponding to the first end cooling medium storage chamber 21, and a cooling medium storage chamber at both ends. It is the heat dissipation core 23; the heat dissipation core 23 is composed of main boards 24 at both ends, heat dissipation pipes 10 connected to the main boards 24 at both ends, heat dissipation fins 25 arranged at intervals with the heat dissipation pipes 10, and side plates 26 on both sides. From figure 1 The structural representation of heat pipe of the present invention shown, figure 2 It can be seen from the schematic diagram of the local structure at the mark A that there is a double-wave structure inner fin inside the heat pipe, and the double-wave structure inner fin includes an upper inner fin 1, a lower inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com