Method and device for determining boiler operation oxygen content and automatic control system

A technology for boiler operation and operating oxygen content, which is applied in the combustion method, combustion control, lighting and heating equipment, etc., to achieve the effect of high-efficiency combustion of NOx concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

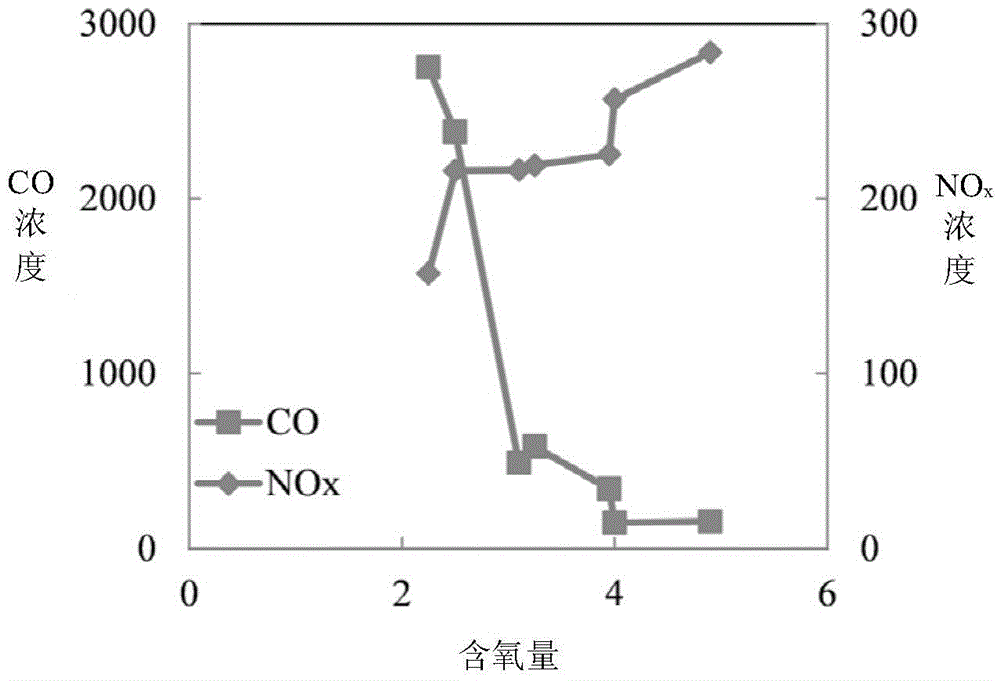

[0043] exist image 3 Under the predetermined steady load shown, CO and NO in flue gas at the denitrification inlet x The specific values of concentration and operating oxygen amount are shown in the table below. According to CO less than 600mg / m 3 The principle of filtering out the first five rows of data, and calculating the corresponding k j Values are shown in the last column of the table, in order of k j The principle of minimum determines that the optimal operating oxygen level under this load is 3.25%.

[0044]

[0045] for Figure 4The best operating oxygen curve of a boiler with a capacity of 2000t / h is shown, and the main steam flow of the boiler is the boiler load. Example of interpolation by finding optimal operating oxygen for any boiler load. For example: the current boiler load (main steam flow) is 1200t / h, at Figure 4 Between (950,5.7) and (1440,3.5) in the two points, there are:

[0046] O 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com