Temperature detector for injection mechanism of extrusion casting machine

A technology for squeeze casting machines and temperature detectors, applied to thermometers, parts of thermometers, thermometers with electric/magnetic elements that are directly sensitive to heat, etc., can solve problems such as poor working conditions of injection mechanisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

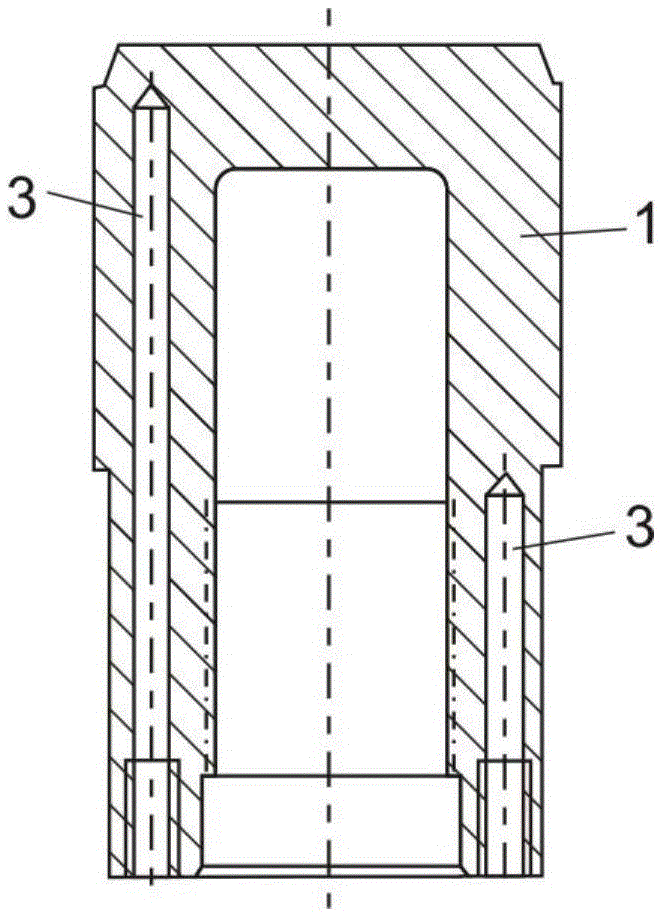

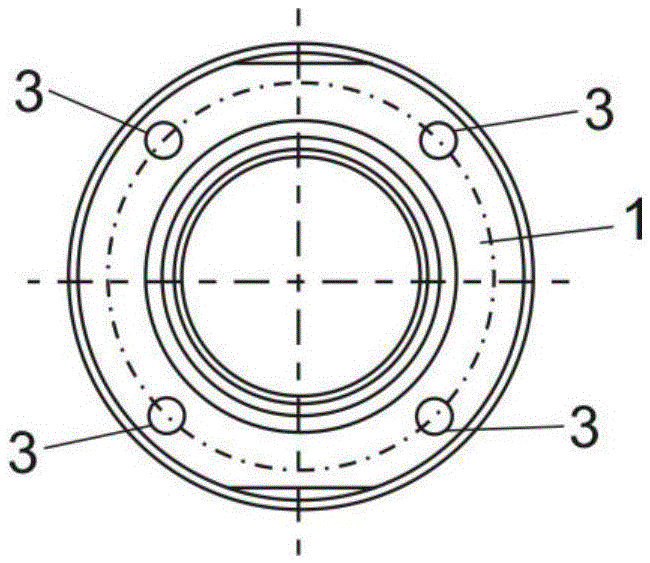

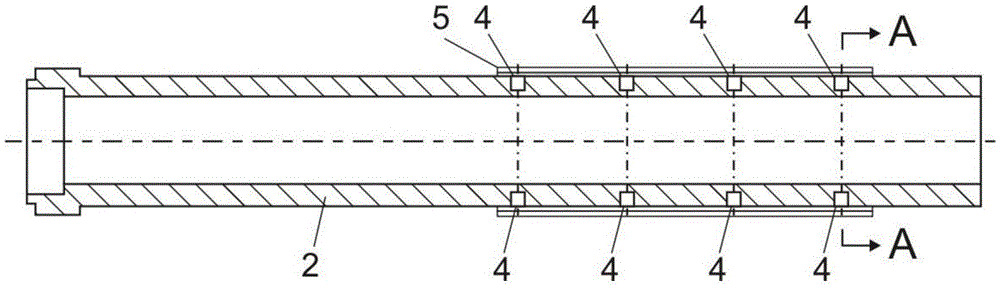

[0014] The injection mechanism of the squeeze casting machine is mainly composed of punch 1, pressure chamber 2 and push rod, among which punch 1 and pressure chamber 2 are the core parts of the injection mechanism and are also the objects of temperature detection. After the molten metal is poured in the pressure chamber 2, it enters the mold cavity from the pressure chamber 2 under the action of the punch 1 to complete the filling and solidification. The matching gap between the punch 1 and the pressure chamber 2 is very small, leaving very limited space for arranging thermocouples. Therefore, the design of the mechanical structure is very critical in the development of the temperature detector of the injection mechanism of the squeeze casting machine. In order not to affect the matching relationship between the punch 1 and the pressure chamber 2, the thermocouple is installed by punching a hole at the detection position.

[0015] At present, there are mainly three types of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com