Dual-layer electric control box and vehicle-mounted machine set

An electric control box, double-layer technology, applied in the direction of electrical components, casings/cabinets/drawer parts, electrical equipment casings/cabinets/drawers, etc., can solve the problem of large space in the electric control box, inconvenient maintenance and factory Internal wiring, unable to meet the space requirements of the unit, etc., to achieve the effect of prolonging the service life, clear and organized wiring, and saving installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

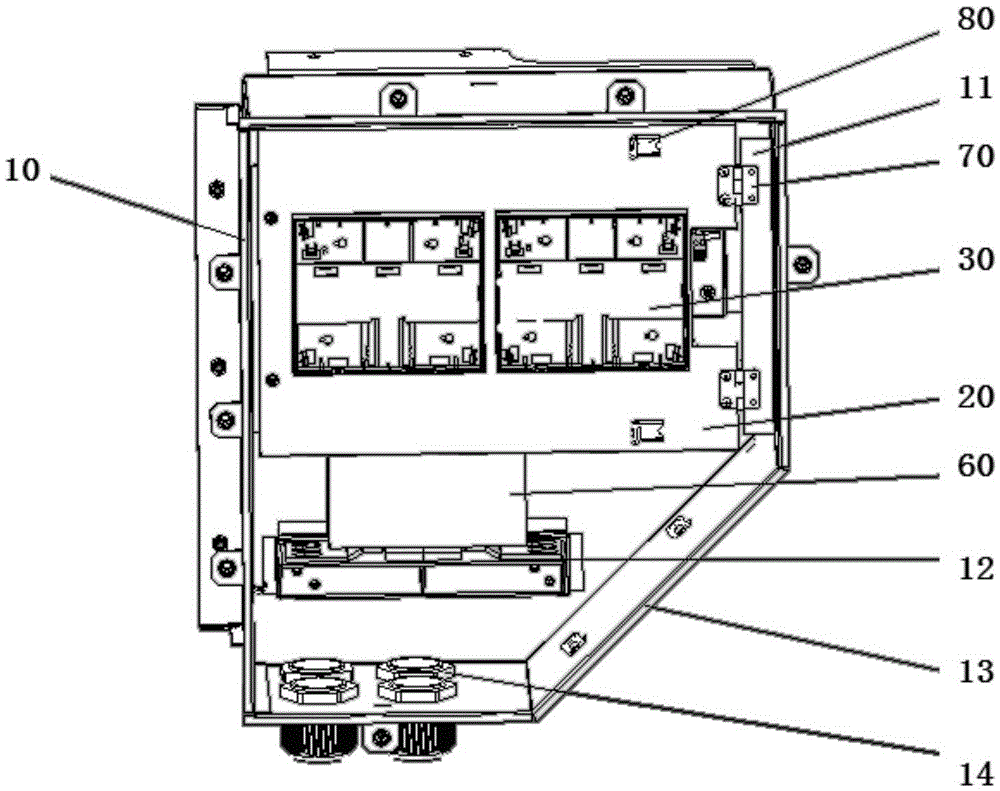

[0057] Such as figure 1 As shown in -5, this embodiment 1 provides a double-layer electric control box, including a box body 10, a partition 20 is installed inside the box body 10, and one end of the partition plate 20 is pivotally connected to the box body 10- The flange 11 inside the side wall, the other end is placed on the flange inside the other side wall opposite to the box body 10, and the inside of the box body 10 is divided into an upper layer and a lower layer by the partition plate 20, and the upper layer is placed on the partition wall. 20, the first component is fixedly arranged, and the second component is fixedly arranged on the box body of the lower layer.

[0058] Preferably, the first component is lighter in weight than the second component. Since the first component is installed on the bulkhead, the center of gravity is higher, so the lighter first component is installed on the higher bulkhead, and the heavier second component is installed on the lower box ...

Embodiment 2

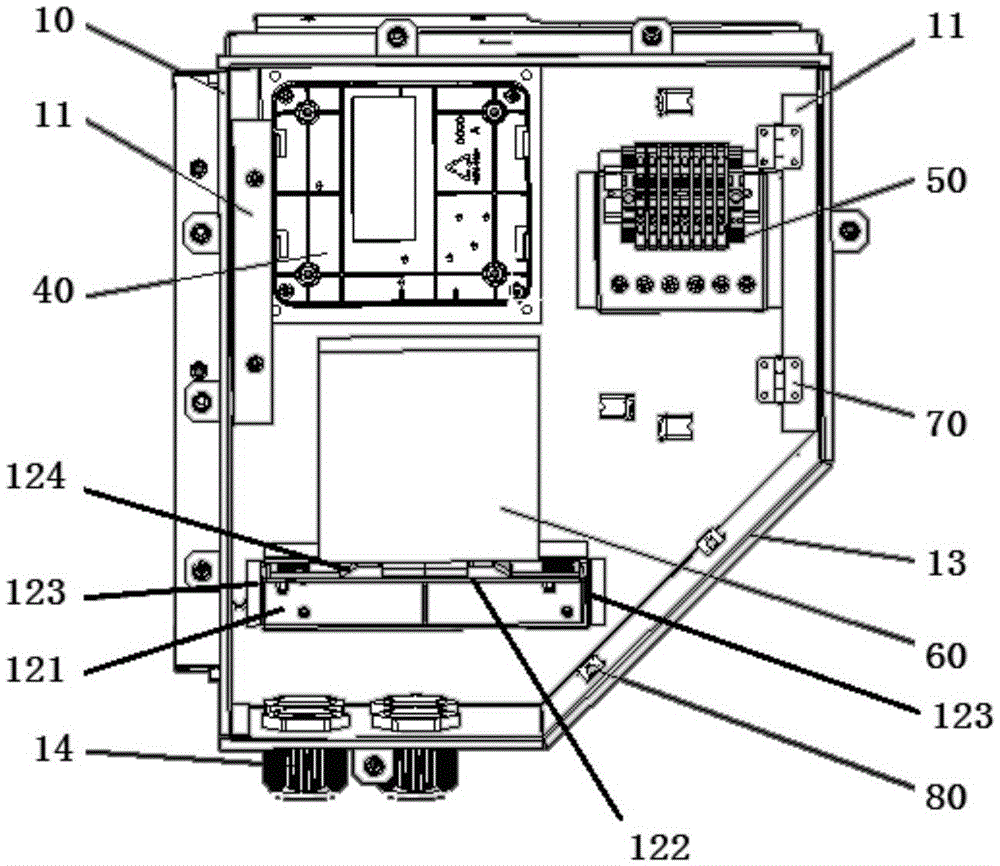

[0064] As shown in Figure 3, the double-layer electric control box provided by this embodiment 2, compared with embodiment 1, in the double-layer electric control box of this embodiment, the partition 20 is a rectangular plate as a whole, One end of the partition 20 is provided with a hinge 70 for hinged connection with the flange 11 on one side of the box body 10, and a plurality of connecting through holes 21 are provided on the partition 20 at the opposite end of the hinge 70, so that The connection through hole 21 is used to connect the other end of the partition plate 20 to the flange 11 on the other side inside the box body 10 . In order to keep the partition plate 20 from moving on the flange 11 , screws, bolts or cable ties can be penetrated into the connection through holes 21 to fix the partition plate 20 . Certainly, the other end of the partition plate 20 can also be fixed on the flange on the other side inside the box body 10 by engaging.

[0065] A plurality of ...

Embodiment 3

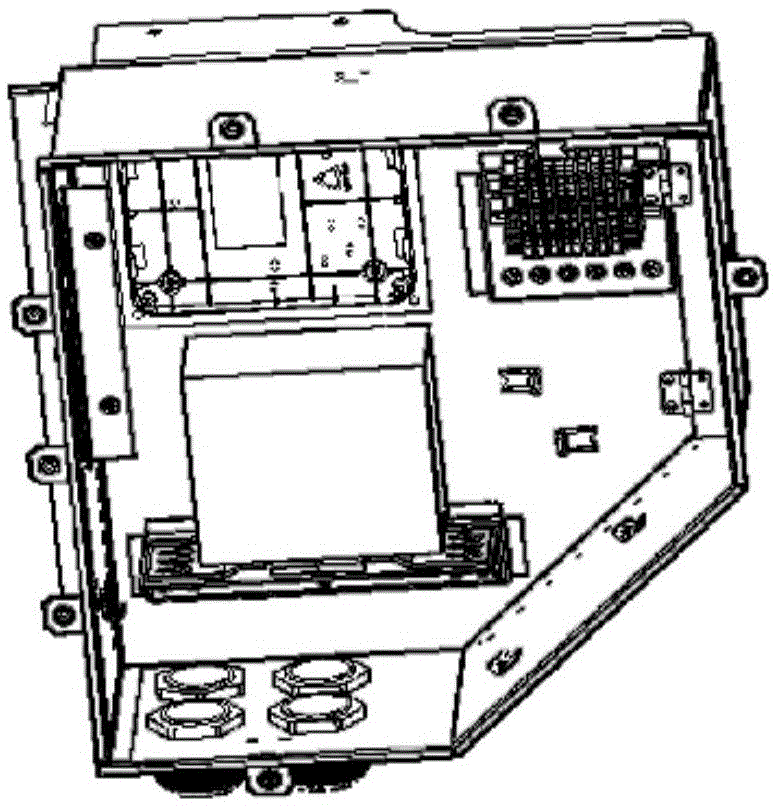

[0072] Such as Figure 4 As shown, a kind of double-layer electric control box described in this embodiment 3, on the basis of embodiment 1 and embodiment 2, the further design is: the box body 10 is a closed box-like structure, and its upper part There is a top cover, and a passing coil 14 for fixing external wiring is provided on the box body 10, and a passing hole is opened on the box corresponding to the installation position of the passing coil 14, and the passing coil 14 is installed on the in the wire hole. Important electric control components such as DDC controller 30 , fan drive board 40 , switching power supply 60 etc. are all installed in the closed box-shaped casing 10 , which can ensure that the electric control components inside are protected by the casing 10 .

[0073] In addition, in order to save valuable unit space, the box body 10 adopts an unconventional shape. On the basis of the existing cuboid shape, a right triangular prism of the cuboid is truncated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com