Bundling bowl tool for bra cup processing

A brassiere and tool technology, applied in brassieres, brassieres, applications, etc., can solve problems such as wrong codes, cylinder differences, appearance and quality differences between left and right cups, bundled bowls, etc., to reduce production costs, improve processing efficiency, and avoid appearance and the effect of quality differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

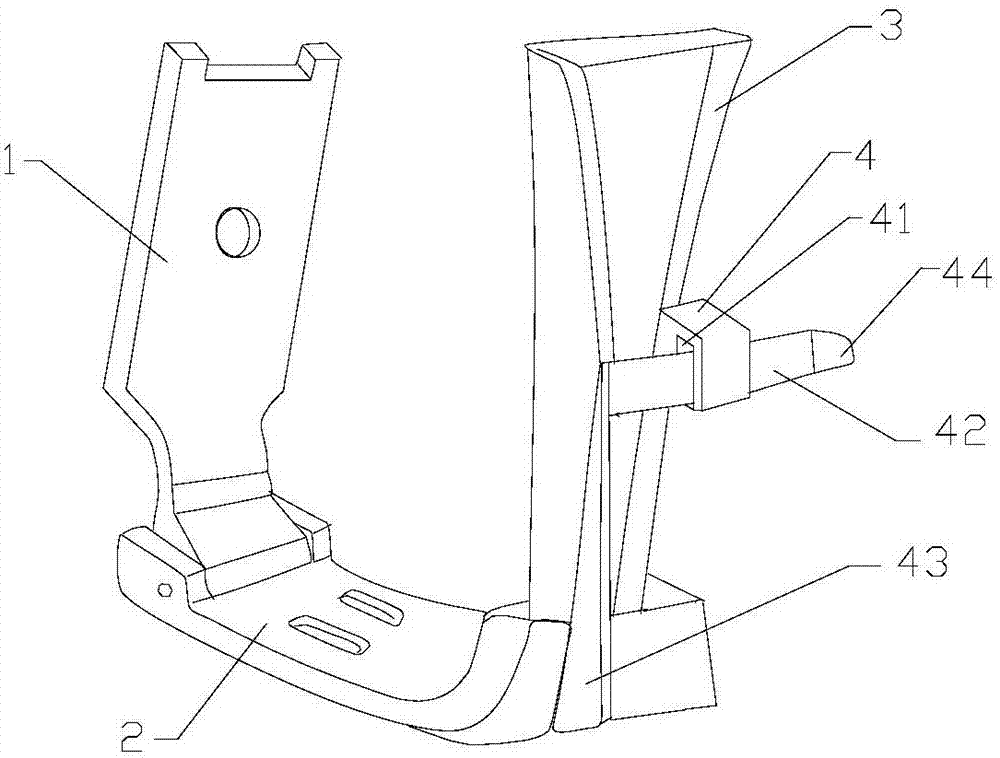

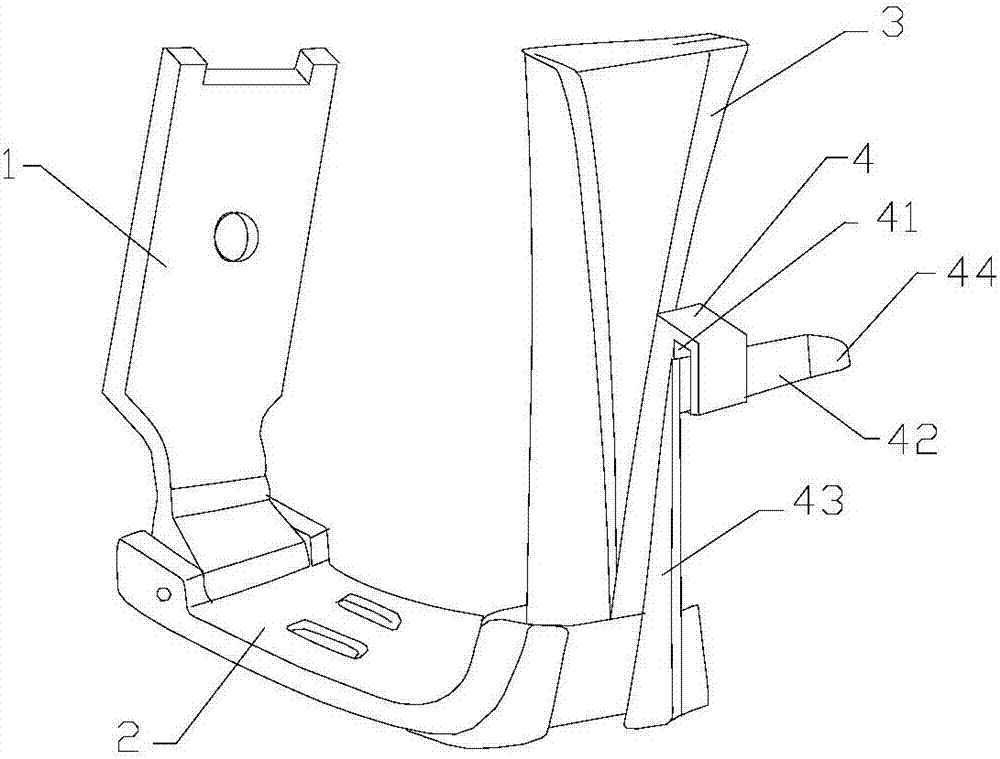

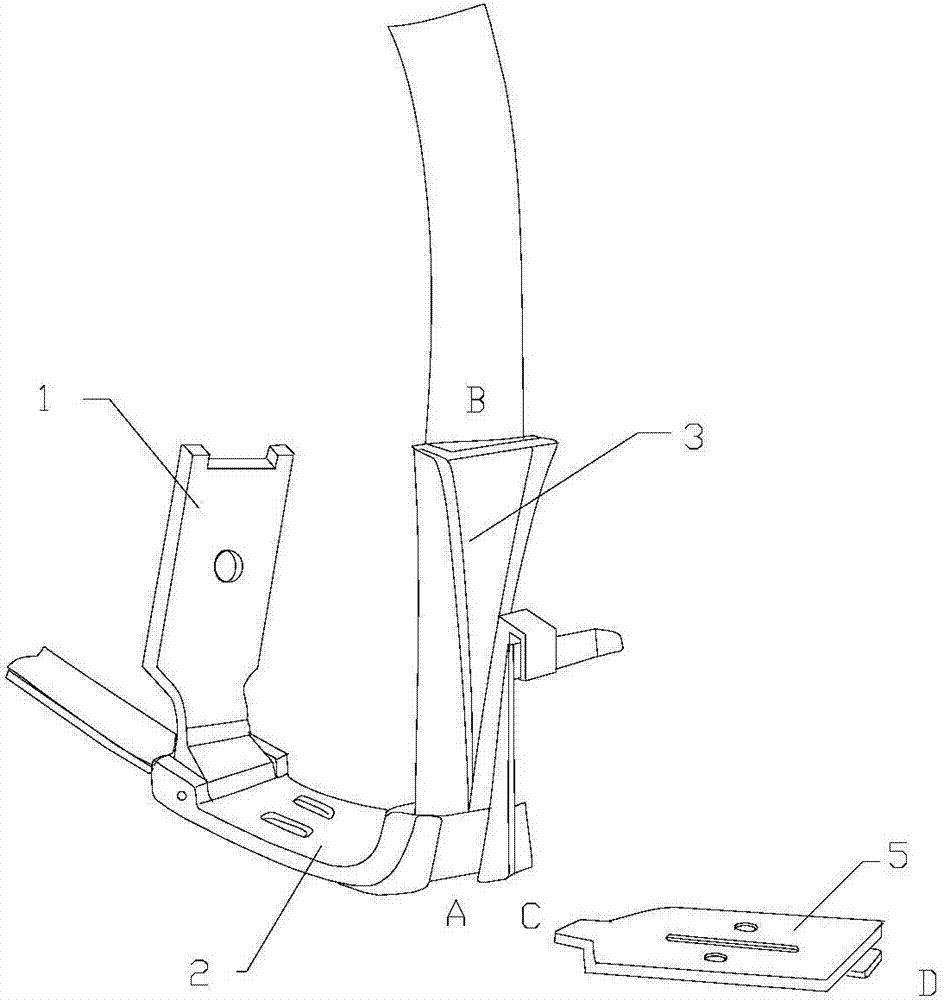

[0018] Attached below figure 1 , figure 2 and image 3 , the present invention is further described:

[0019] Such as figure 1 As shown in , the present invention includes a presser foot fixing plate 1 for fixing the present invention on sewing equipment, said presser foot fixing plate 1 is perpendicular to the operation plane of the sewing machine, connected on the presser foot fixing plate 1 and parallel to The presser foot 2 of the operating plane of the sewing machine and the vertically arranged binding rod pull cylinder 3 connected on the presser foot 2 have the same structure as the prior art.

[0020] In order to achieve the purpose of the present invention, the process step of replacing the accessories of the binding bowl is omitted during the binding bowl process, and a movable baffle mechanism that can move left and right is arranged on the bundle rod puller 3; the movable baffle mechanism A movable baffle plate 43 of the plate mechanism is placed at the lower p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com