A feeding device and method for feeding rivets in a riveting production line

A production line and rivet technology, applied in the field of rivet feeding devices for riveting production lines, can solve the problems of poor labor conditions, high labor intensity, low production efficiency, etc., and achieve the effects of facilitating feeding operations and reducing risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

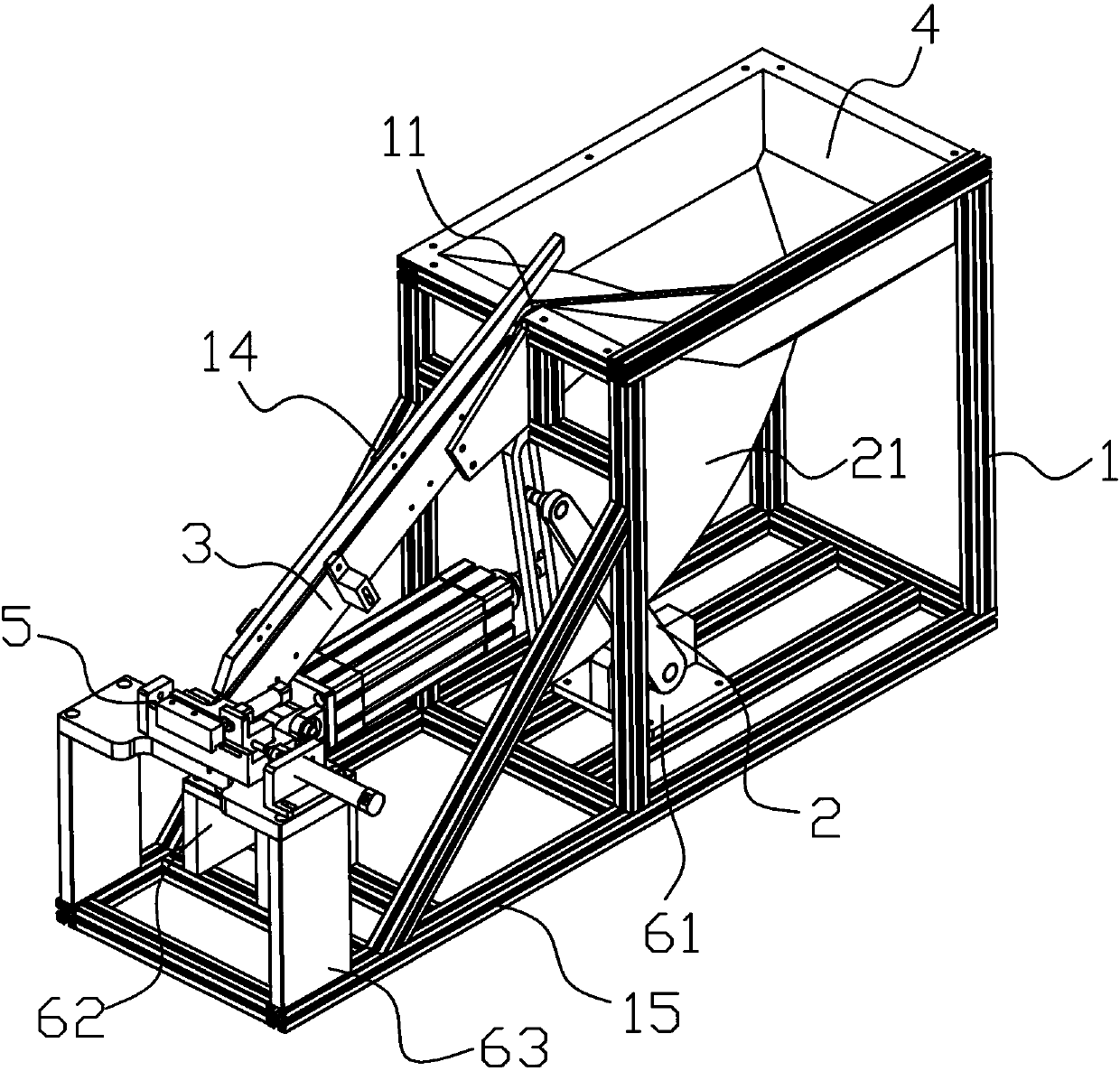

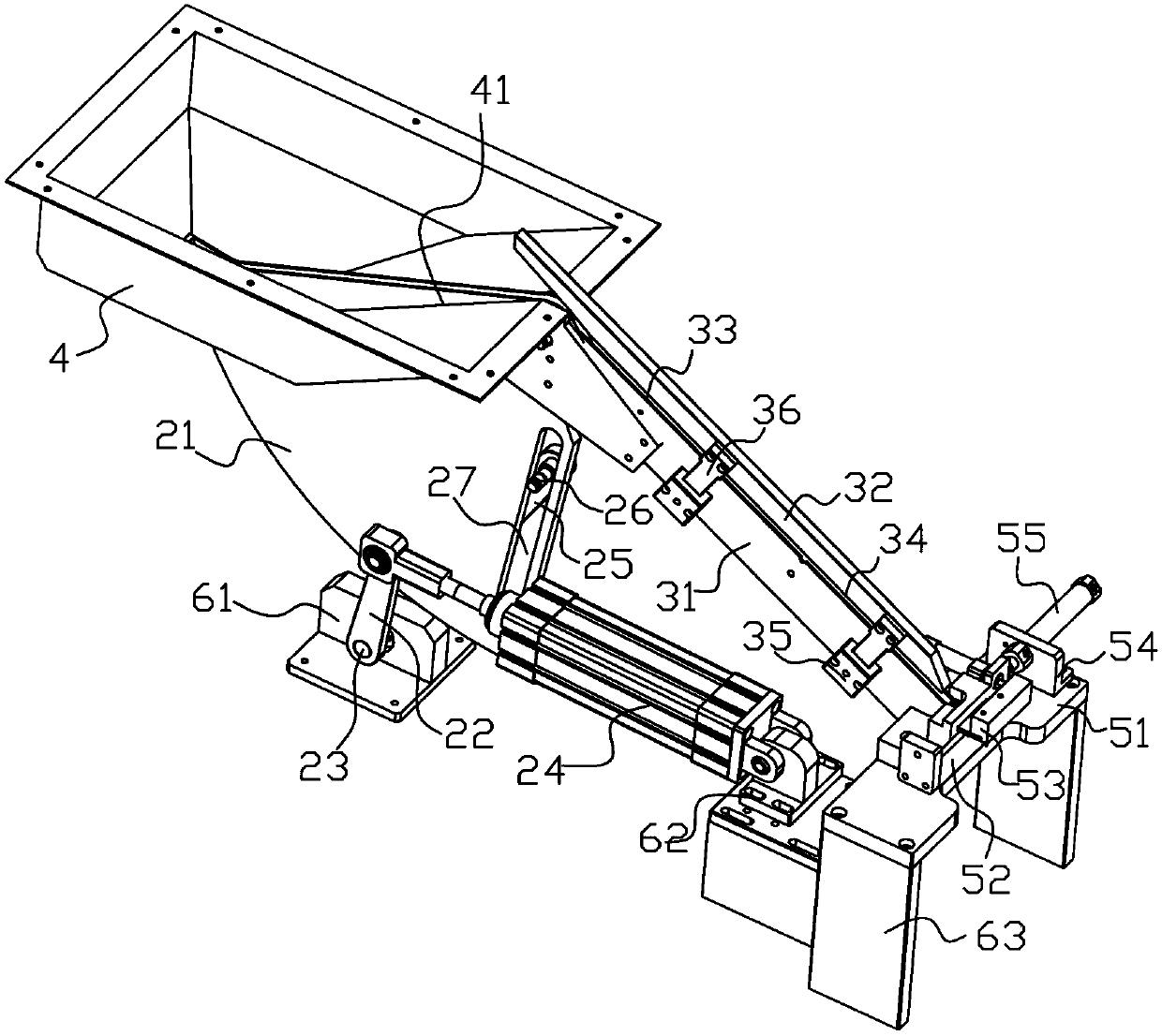

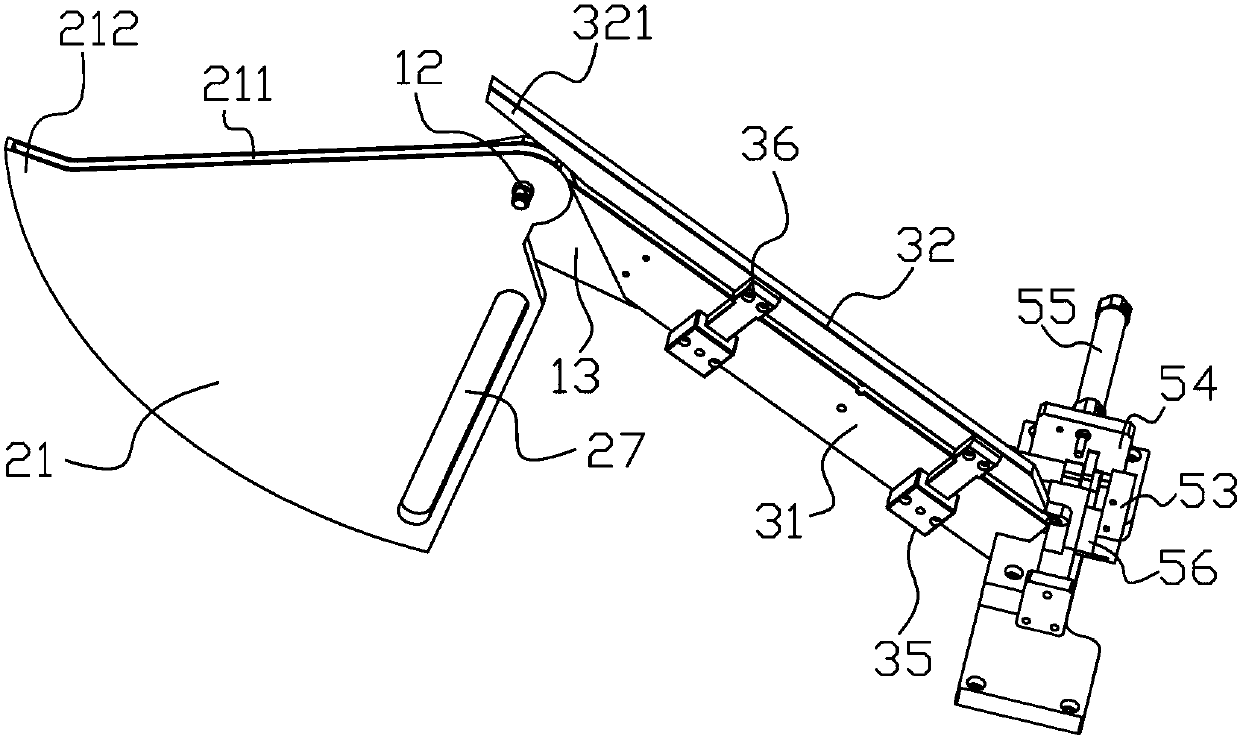

[0034] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0035] Frame 1, feeding mechanism 2, guiding mechanism 3, feeding hopper 4, positioning mechanism 5, gap 11, connecting shaft 12, connecting plate 13, supporting rod 14, box 15, sector plate 21, connecting rod 22, rotating shaft 23. Oil cylinder 24, rocker arm 25, sliding shaft 26, chute 27, lower guide plate 31, upper guide plate 32, guide groove 33, channel 34, clamping block 35, positioning bar 36, strip hole 41, the second Pushing cylinder 51, base 52, baffle plate 53, cylinder seat 54, first pushing cylinder 55, unloading plate 56, sliding seat 57, first hinge seat 61, second hinge seat 62, support Seat 63, rivet correction groove 211, protrusion 212, discharge hole 511, waist-shaped hole 522, limit pin 523.

[0036] Such as Figures 1 to 10 As shown, a feeding device for rivets in a riveting production line, which includes a frame 1 that provides support for e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com