CNC working table

A technology of workbench and manipulator, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., and can solve problems such as inability to process in all directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

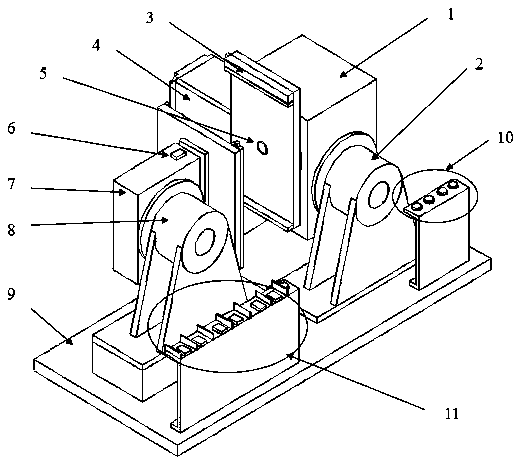

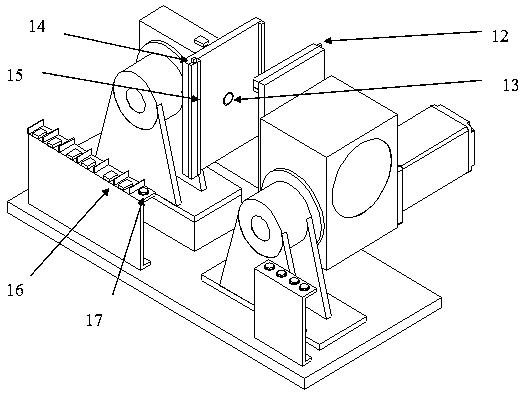

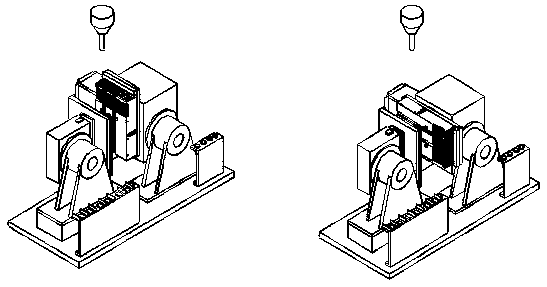

[0035] The invention discloses a CNC workbench, which includes a telescopic manipulator and a four-axis extension manipulator. The four-axis extension manipulator includes a first base, a first rotating cylinder, an indexer, and a first clamping device. The first clamping device is arranged on the indexer. , and the rotation is realized by an indexer, the indexer is connected to the first rotary cylinder, and the rotation is realized by the first rotary cylinder, and the first rotary cylinder is fixed on the first base. The four-axis extension manipulator also includes a motor for driving the rotation of the indexer. The first clamping device is a claw. The first clamping device is provided with a first sensor, and the first sensor is used for judging whether it is in contact with the product. The telescopic manipulator includes a second base, a second rotating cylinder, a telescopic cylinder, and a second clamping device. The second clamping device is arranged on the telesco...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap