PCB circuit board fixed processing equipment

A PCB circuit board and processing equipment technology, applied in the direction of printed circuit, printed circuit manufacturing, electrical components, etc., can solve the problems of time-consuming, labor-intensive efficiency, low reliability, and inability to process PCB boards, so as to ensure front, rear, left, and right movement, The effect of novel design and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

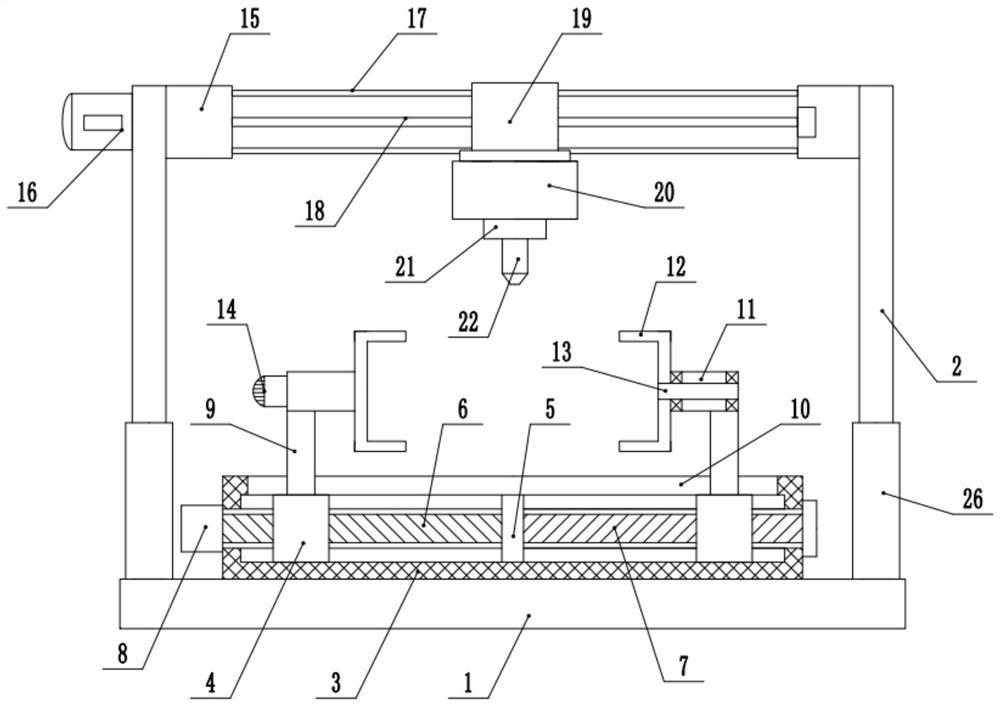

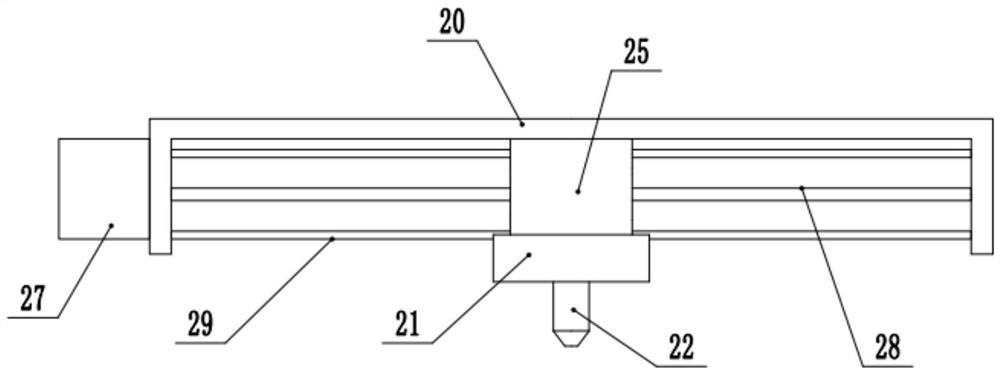

[0028] refer to Figure 1~3 , in an embodiment of the present invention, a PCB circuit board fixed processing equipment includes a fixed bottom plate 1, a limit cylinder 3 is installed in the middle of the upper end of the fixed bottom plate 1, and a partition plate 5 is installed in the middle of the limit cylinder 3 to avoid The two moving blocks 4 are in direct contact with each other during the moving process, and a left-handed threaded rod 6 and a right-handed threaded rod 7 connected to each other are installed inside the limit cylinder 3. By setting two threaded rods with opposite rotations, the two moving blocks 4 Movement in the opposite direction occurs during the moving process, and the left end of the left-handed threaded rod 6 is fixed with a drive motor 8, which is used to provide a power source for the movement of the moving block 4. The left-handed threaded rod 6 and the middle part of the right-handed threaded rod 7 are respectively equipped with Moving block ...

Embodiment 2

[0030] refer to Figure 4 , in another embodiment of the present invention, the difference between this embodiment and the above embodiment is that a spring group 23 is installed on the inner side of the U-shaped fixing plate 12, and a positioning plate 24 is installed on the other end of the spring group 23, through Setting the spring group 23 and the positioning plate 24 can clamp and position PCB boards of different widths.

[0031] In the present invention, when working, the PCB board to be processed is fixed between the fixed U-shaped fixing plates 12, and then the driving motor 8 is started to drive the left-handed threaded rod 6 and the right-handed threaded rod 7 to rotate, thereby passing through two different moving directions The function of the moving block 4 makes the U-shaped fixed plates 12 close to each other to realize the fixed clamping of the PCB board. At this time, we can determine which side of the PCB board to process by controlling the rotating motor 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com