A dual-spindle hydraulic lathe with high-efficiency intelligent spindle

A dual-spindle and spindle technology, which is applied in the field of hydraulic lathes and dual-spindle hydraulic lathes, can solve problems such as low efficiency, and achieve the effects of improving production efficiency, comprehensive processing, and reducing the footprint of machine tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

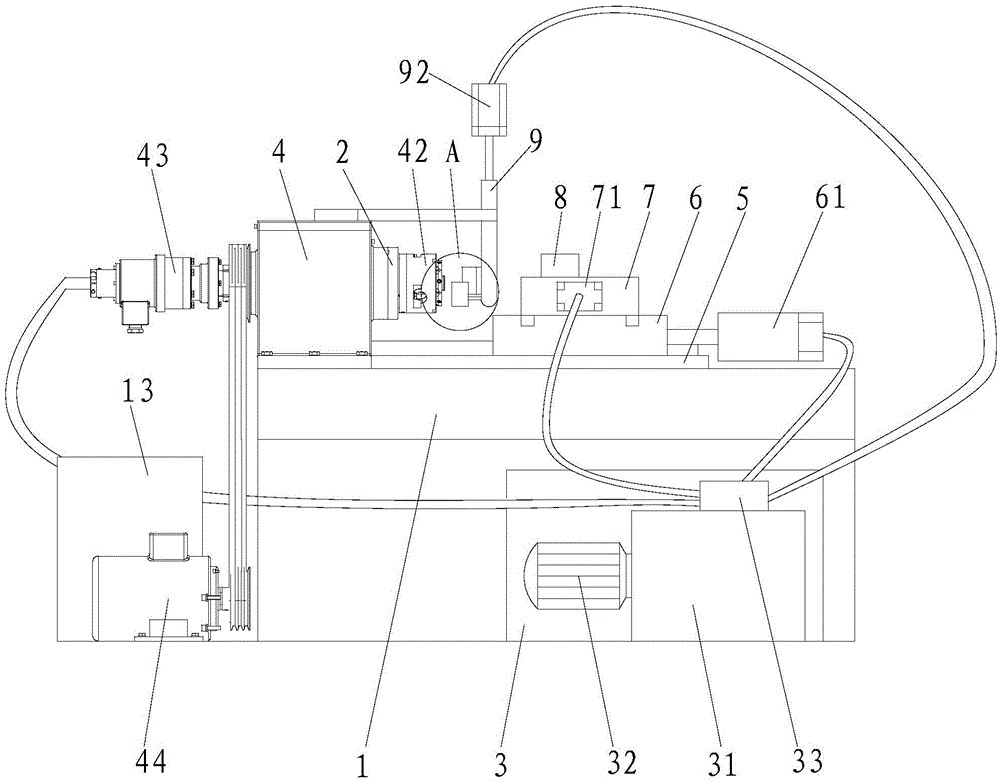

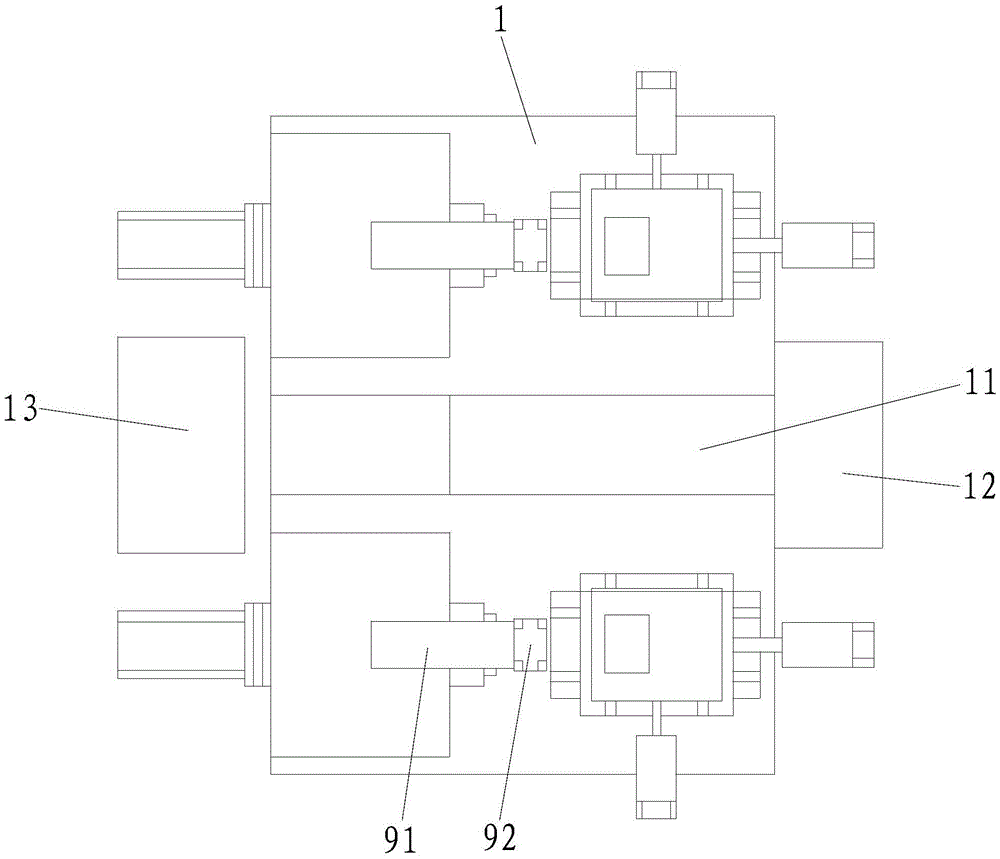

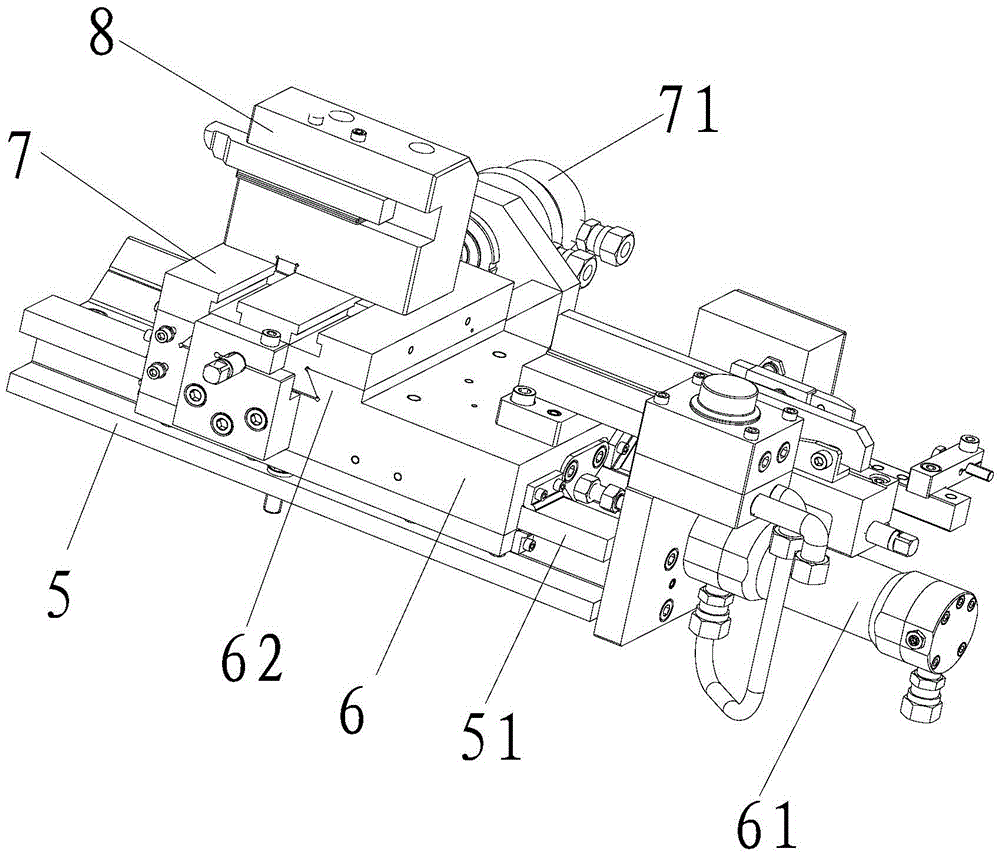

[0020] refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the present invention adopts a dual-spindle hydraulic lathe with high-efficiency intelligent spindles, comprising a machine tool 1, an electrical control box 13, a hydraulic system 3 and two spindle boxes 4, and the two spindle boxes 4 are respectively installed on both sides of the machine tool 1, and the spindle boxes 4 is installed with intelligent main shaft 2, the front end of intelligent main shaft 2 is equipped with hydraulic clamp 42, the end of intelligent main shaft 2 is equipped with clamp oil cylinder 43, and electric control box 13 is connected with two motors 44, and motor 44 drives intelligent through V-shaped belt. Main shaft 2, the intelligent main shaft 2 includes a housing 21, a rotating shaft 22, an eddy current sensor 241, an embedded processor 242, an input panel 243 and an alarm device 244, the rotating shaft 22 is installed in the housing 21, and one end of the rotating shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com