Automatic folding and gluing apparatus for packing boxes

A packaging box and gluing technology, which is applied in the field of automatic folding and gluing equipment for packaging boxes, can solve problems such as increased labor costs, scrapped packaging boxes, and prone to deviations in the placement of top stickers, so as to improve quality and save labor costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

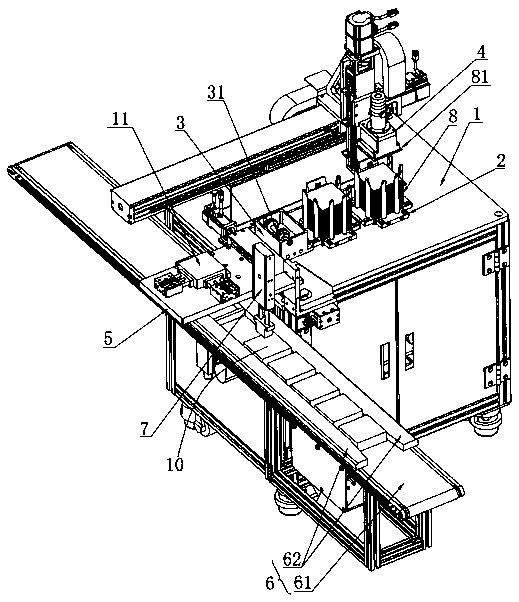

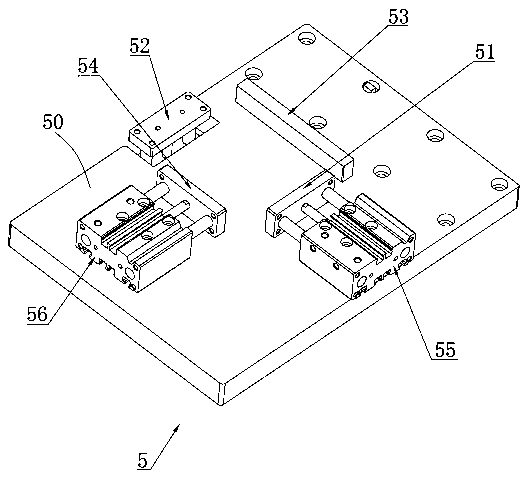

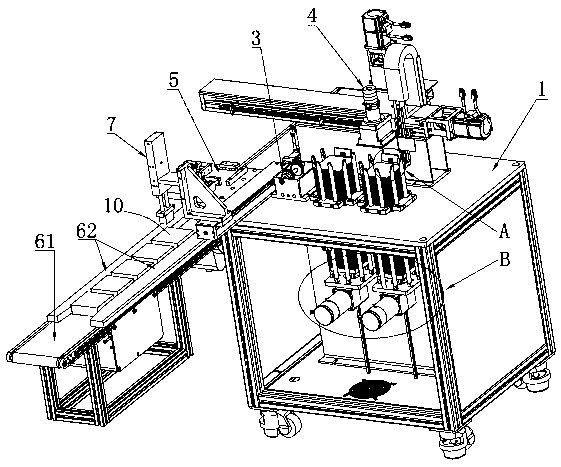

[0021] Such as figure 1 As shown, the packaging box automatic folding and gluing equipment of this embodiment includes a frame 1, two feeding devices 2, a transfer manipulator 4, a glue box 3, a packaging table 5, a feeding manipulator 7 and a conveying device 6, combined Figure 3-5 , the feeding device 2 includes a base plate 24, some fences 21 and a material lifting mechanism 23, each fence 21 bottom is fixed with the base plate 24, and the material lifting mechanism 23 includes a material lifting motor 231, a material lifting rod 233 and a material lifting plate 232, and the lifting material The top of the rod 233 is fixed on the lifting plate 232, the lifting plate 232 is positioned abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com