Flour conveying and loading device

A transmission device and flour technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of heavy flour burden and low efficiency, and achieve the effect of convenient installation and improved operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

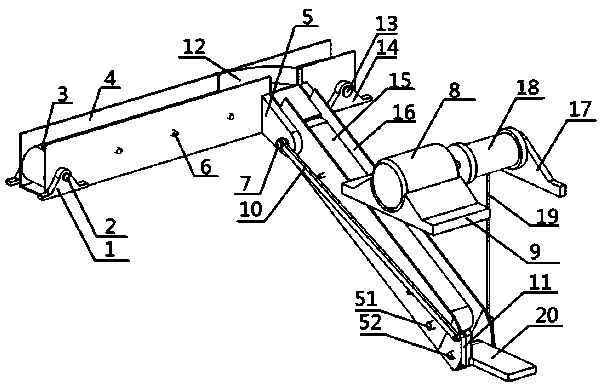

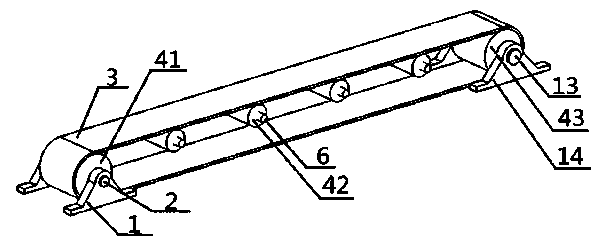

[0015] Such as figure 1 , figure 2 As shown, the present invention is made up of horizontal forward conveying device and inclined downward conveying device; Horizontal forward conveying device comprises forward conveying system and arc-shaped baffle 12 on it; Described inclined downward conveying device comprises descending conveying system and adjustment Lifting angle system.

[0016] The conveyor belt power of the forward transmission system is provided by the drum motor 43, the rotating shaft one 13 of the drum motor 43 is fixed on the bearing housing one 14, the driven roller rotating shaft one 2 is fixed on the bearing housing two 1, and the transition roller of the transition roller 42 The rotating shaft 6 is fixed on the horizontal conveyor housing 4, and the horizontal conveyor housing 4 is provided with an arc-shaped baffle 12. The effect of arc baffle 12 is to facilitate the object turning straight on the conveyor belt 3 . When the material on the conveyor belt 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com