Apparatus and method for evaluating corrosion resistance of metal composite pipe

A metal composite pipe, corrosion-resistant technology, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, strength characteristics, etc., can solve the difficulty of standard samples, can not reflect the corrosion resistance of composite pipes, and cannot fully reflect the inner layer mechanics State and other issues, to achieve the effect of accurate corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] This example provides a device and method for on-site evaluation of the corrosion resistance of metal composite pipes at Tiandong 5-1.

[0069] Natural gas is transported in the Tiandong 5-1 site pipeline.

[0070] Tiandong 5-1 site working conditions (during the test): pressure 10.1MPa, temperature 60-70℃, hydrogen sulfide concentration 87.4g / m 3 , carbon dioxide concentration 50.6g / m 3 , the chloride ion content in the product water is 24700mg / L, the total hardness is 1407mg / L, and the bicarbonate ion is 3180mg / L.

[0071] The metal composite pipe tested is a metal composite pipe composed of L245 carbon steel and 825 alloy steel, and the metal composite pipe has a weld seam in the length direction.

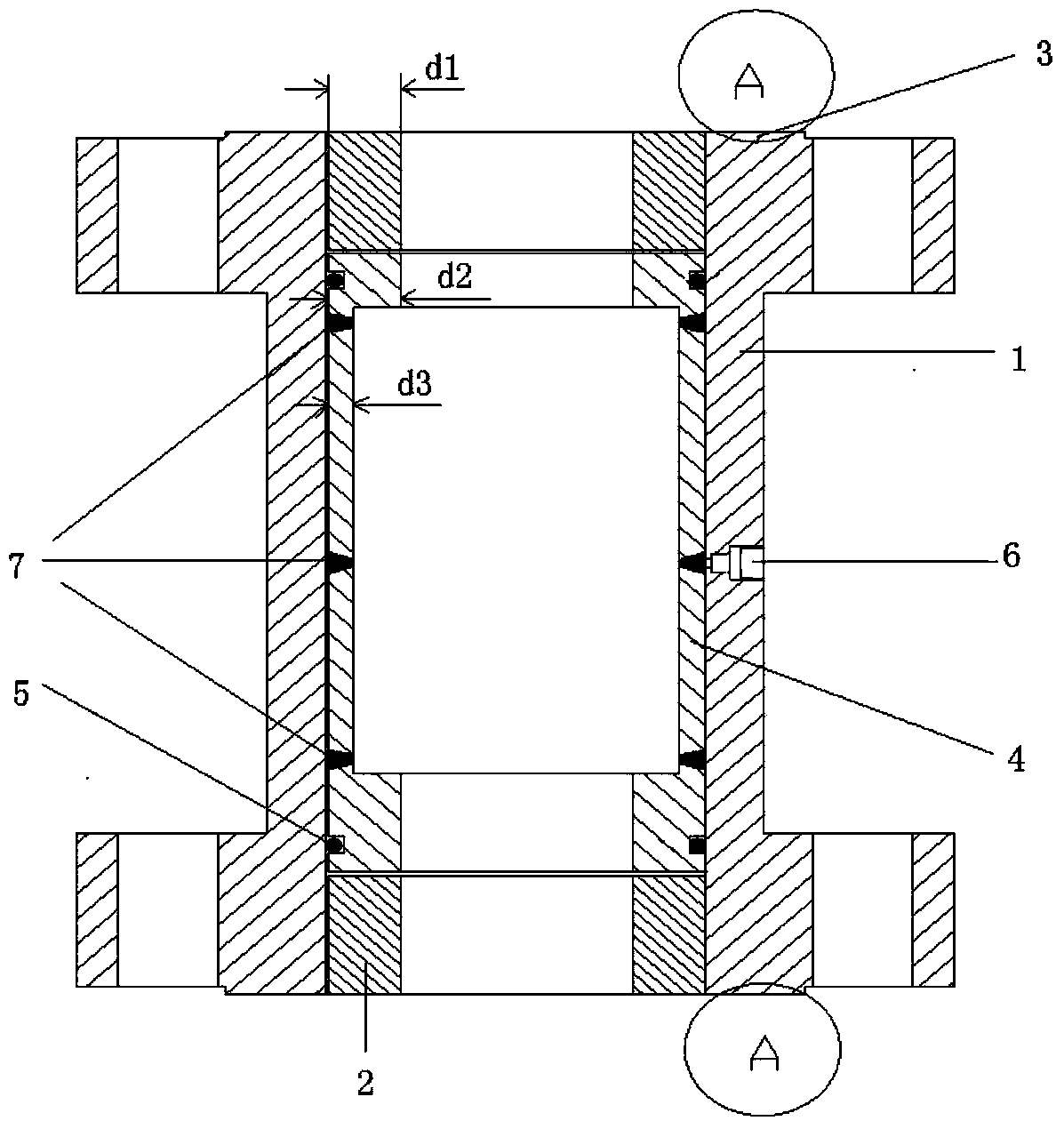

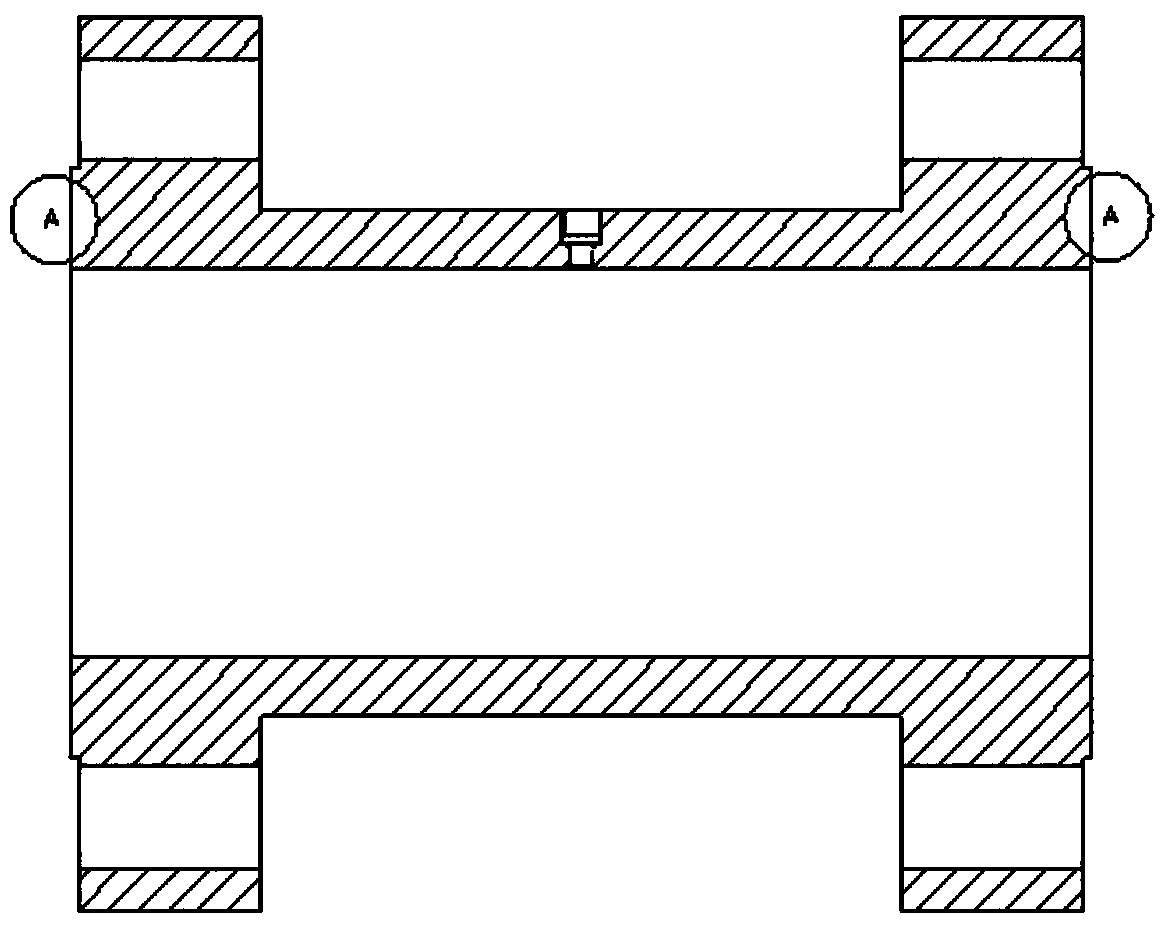

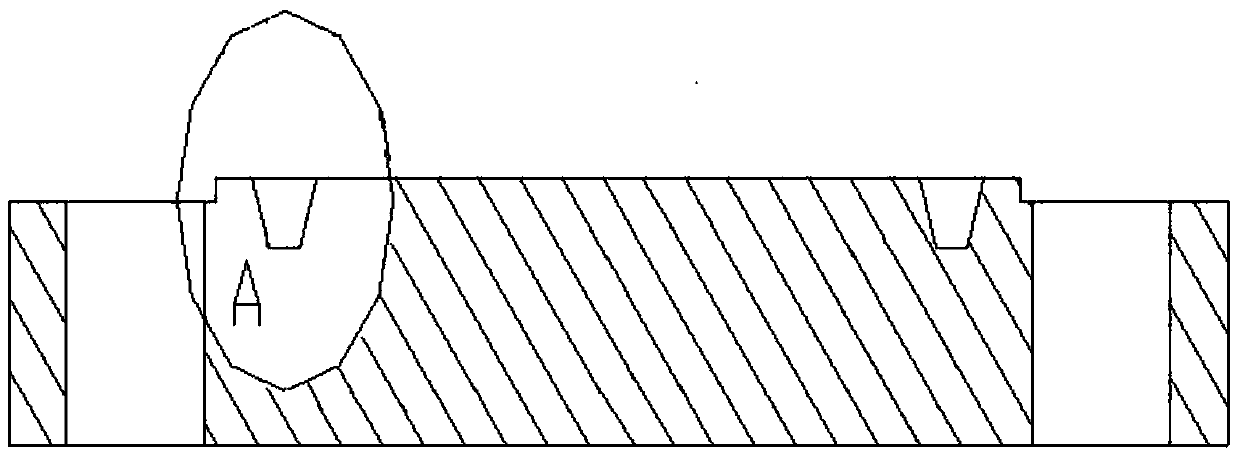

[0072] Design and manufacture the main casing 1, the metal bushing 2 and the metal sealing ring 3 according to the parameters of the on-site bypass device of the Tiandong 5-1 well station and the size of the metal composite pipe to be tested.

[0073] The structure of ...

Embodiment 2

[0085] This example provides a device and method for on-site evaluation of the corrosion resistance of metal composite pipes at Tiandong 5-1.

[0086] In this embodiment, it is the same as that in Embodiment 1 except that the metal composite pipe is replaced by a metal composite pipe composed of L360 carbon steel and 825 alloy steel.

[0087] After the experiment was carried out for 15 days, the pressure indication number decreased significantly, indicating that the metal composite pipe had cracked. Subsequent testing of the metal clad pipe is not required.

[0088] This embodiment also shows that the device and method of the present invention can evaluate the corrosion resistance of the entire metal composite pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com