Visualized analysis method for temperature field of continuous casting crystallizer

A continuous casting crystallizer and analysis method technology, applied in the field of iron and steel metallurgical continuous casting, can solve the problems of inability to realize temperature monitoring, failure to consider the temperature field distribution of the crystallizer, inaccurate temperature field cloud map, etc., and achieve a friendly man-machine interface , optimize the temperature distribution state, and improve the effect of analysis level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific embodiment of the present invention is further described below:

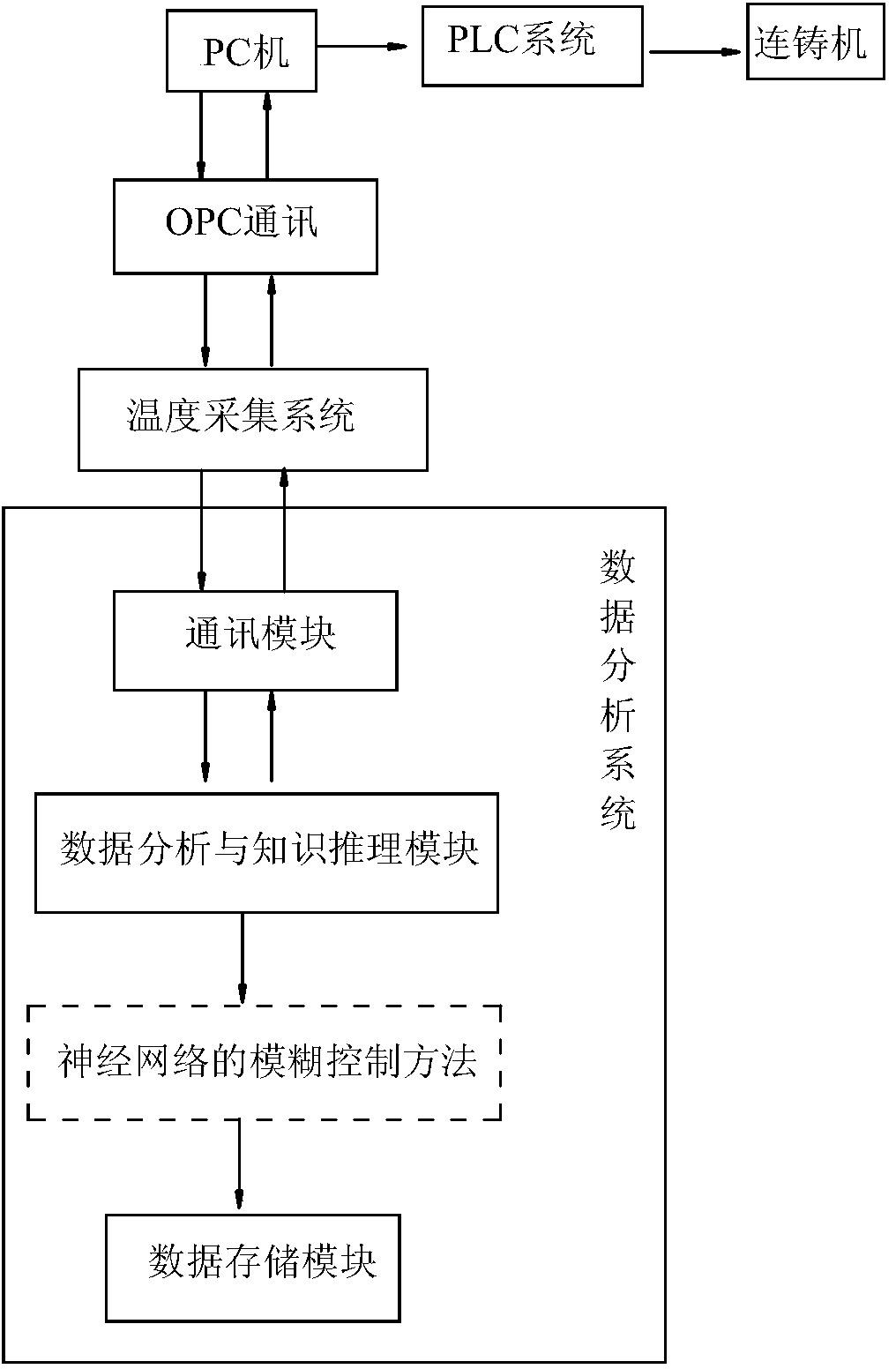

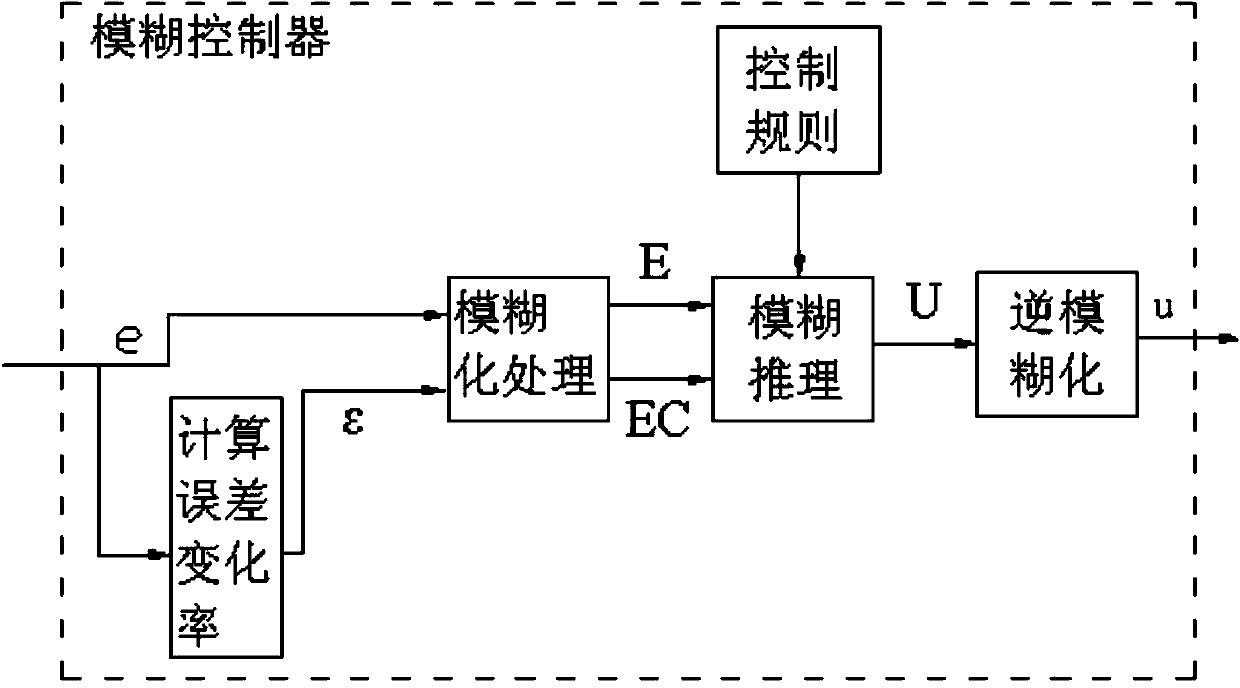

[0036] A visual analysis method for the temperature field of a continuous casting mold, through the fuzzy control method of the neural network, realizes arbitrary visual temperature monitoring of the internal temperature field of the mold, and performs visual analysis of the pouring process and temperature field of the mold. The specific operation steps are as follows:

[0037] 1) The temperature data of the casting process of the crystallizer is collected through the temperature acquisition system in the PC. Based on the multi-channel parallel data bandwidth of OPC communication and the parallel data flow of the data communication interface of the continuous casting machine, large-throughput data flow is allowed to realize the The temperature data during the pouring process of the crystallizer is collected, and the thermocouple thermoelectric potential is converted into Kelvin temperature;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com