Mercury internally-cooled asynchronous motor rotor capable of improving running property and cooling capability

An asynchronous motor and cooling capacity technology, applied in cooling/ventilation devices, electromechanical devices, electrical components, etc., can solve the problems of cumbersome auxiliary equipment, power grid harmonic pollution, motor structure deformation, etc., to improve service life and avoid harmonics. Contamination, overheating prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

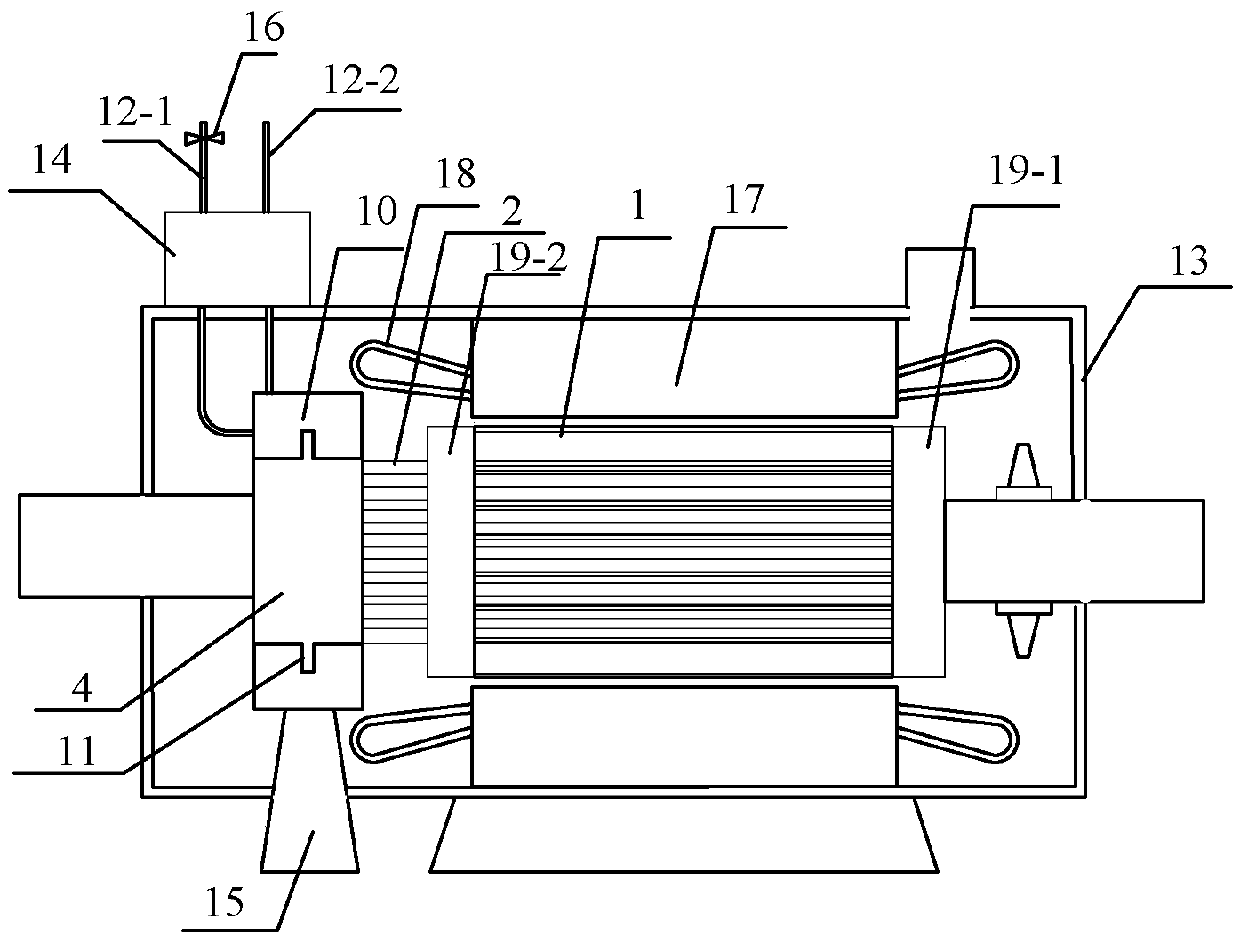

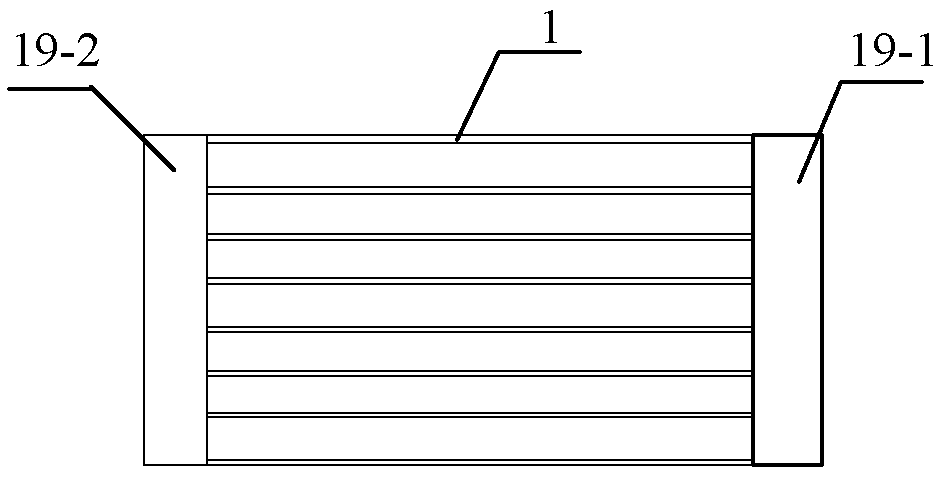

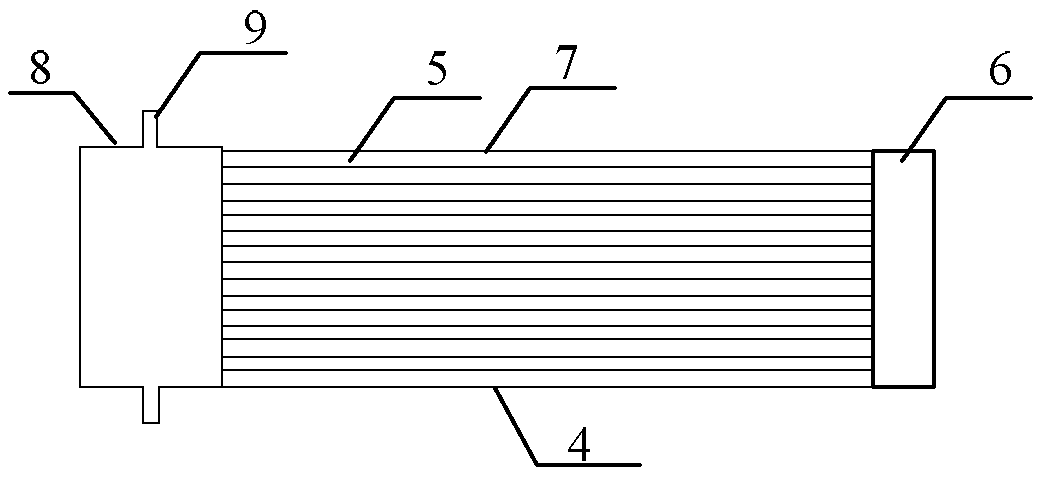

[0024] Exemplary embodiments of the present invention will be described below with reference to the accompanying drawings. In the interest of clarity and conciseness, not all features of an actual implementation are described in this specification. It should be understood, however, that in developing any such practical embodiment, many implementation-specific decisions must be made in order to achieve the developer's specific goals, such as meeting those constraints related to the system and business, and those Restrictions may vary from implementation to implementation. Furthermore, it should be understood that development work, while potentially complex and time-consuming, would be a routine undertaking for those skilled in the art having the benefit of this disclosure.

[0025] Here, it should also be noted that, in order to avoid obscuring the present invention due to unnecessary details, only the device structure and / or processing steps closely related to the solution ac...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap