Double-sided effect elastic indigo warp-knitted denim fabric and its preparation process

A double-sided effect, denim fabric technology, applied in warp knitting, knitting, textiles and papermaking, etc., can solve the problem that the weft extension is difficult to meet the dimensional stability requirements of clothing, and achieve unfettered, soft and friendly good skin effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

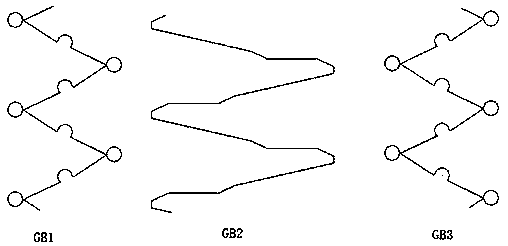

Image

Examples

Embodiment 1

[0045] A double-sided effect elastic indigo warp-knitted denim fabric, which is composed of the following mass percentage components: 50.3% of 75D / 36F absorbent polyester DTY, 40.3% of 32s indigo yarn, and 9.4% of 40D spandex. The fabric is exposed on the reverse side for moisture absorption Sweat-wicking polyester yarn with exposed indigo yarn on the front of the garment, and spandex sandwiched between the front and back.

Embodiment 2

[0047] A double-sided effect elastic indigo warp-knitted denim fabric is composed of the following mass percentage components: 50D / 24F moisture-absorbing and sweat-wicking polyester DTY is 48.2%, 40s indigo yarn is 42.1%, and 40D spandex is 9.6%. The fabric is worn on the reverse side Moisture-wicking polyester threads are exposed, indigo yarn is exposed at the front of the garment, and spandex is sandwiched between the front and back.

[0048] The preparation process of the warp-knitted denim fabric includes single-comb structure selection, preparation process, warping, weaving, and setting. The specific process is as follows:

[0049] 1. Preparation process

[0050] Choose 21s~60s white cotton yarn, warp it, and then use the dyeing machine to carry out bundle-shaped indigo reduction dyeing, then divide the warp through the warp splitting machine, and then go through the tube making machine to make indigo cheese yarn; choose 50D~100D moisture-absorbing and sweat-wicking poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com