Preparation method and equipment of degradable non-woven fabric

A technology of non-woven fabrics and polyester fibers, applied in textiles and papermaking, non-woven fabrics, rayon manufacturing, etc., can solve the problems of unbalanced properties of polymer components and poor comprehensive performance of non-woven fabrics, and achieve reliable quality , improve efficiency, simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

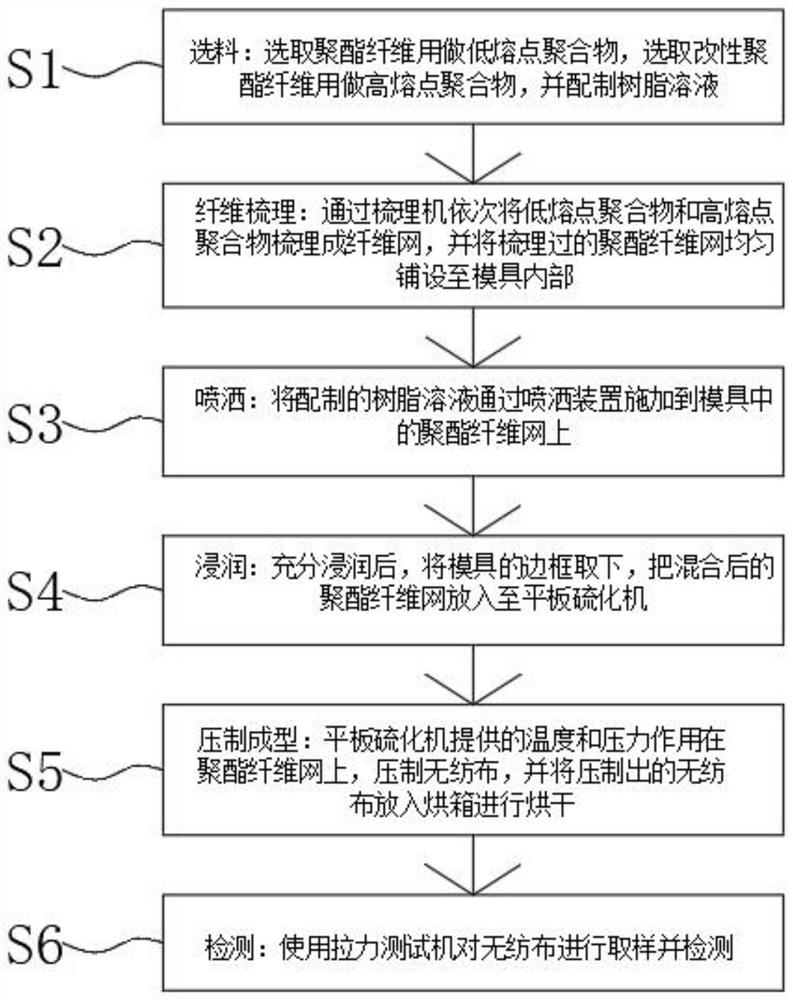

[0039] see figure 1 , a preparation method of degradable non-woven fabric, comprising the steps of:

[0040] S1: Material selection: select polyester fiber as a low melting point polymer, select modified polyester fiber as a high melting point polymer, and prepare a resin solution;

[0041] S2: Fiber carding: the low-melting point polymer and the high-melting point polymer are sequentially carded into a fiber web by a carding machine, and the carded polyester fiber web is evenly laid inside the mold;

[0042] S3: spraying: applying the prepared resin solution to the polyester fiber net in the mold through a spraying device;

[0043] S4: Infiltration: After fully infiltrating, remove the frame of the mold, and put the mixed polyester fiber net into the flat vulcanizing machine;

[0044] S5: Press forming: the temperature and pressure provided by the flat vulcanizer act on the polyester fiber net to press the non-woven fabric, and put the pressed non-woven fabric into an oven ...

Embodiment 2

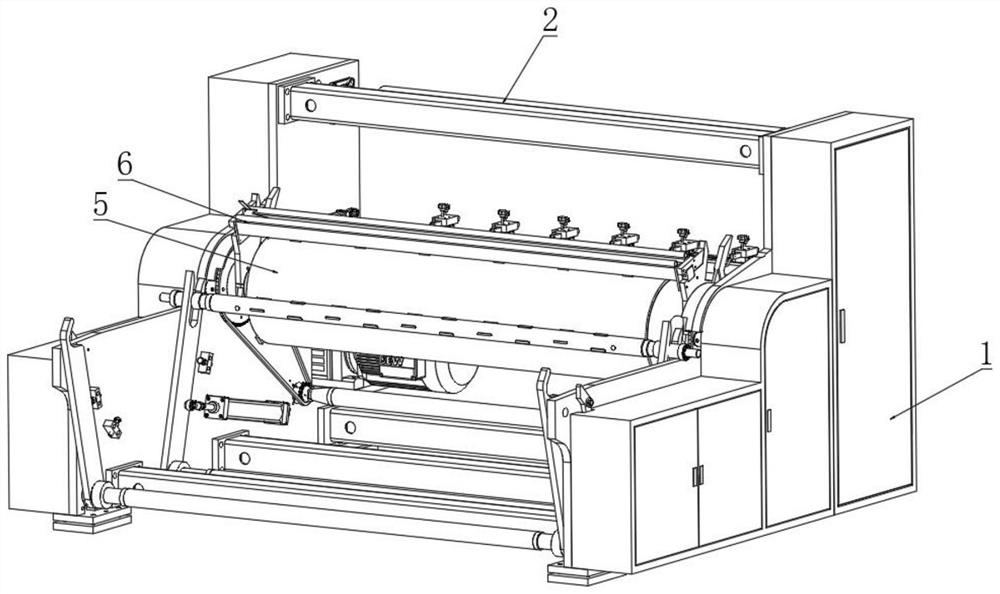

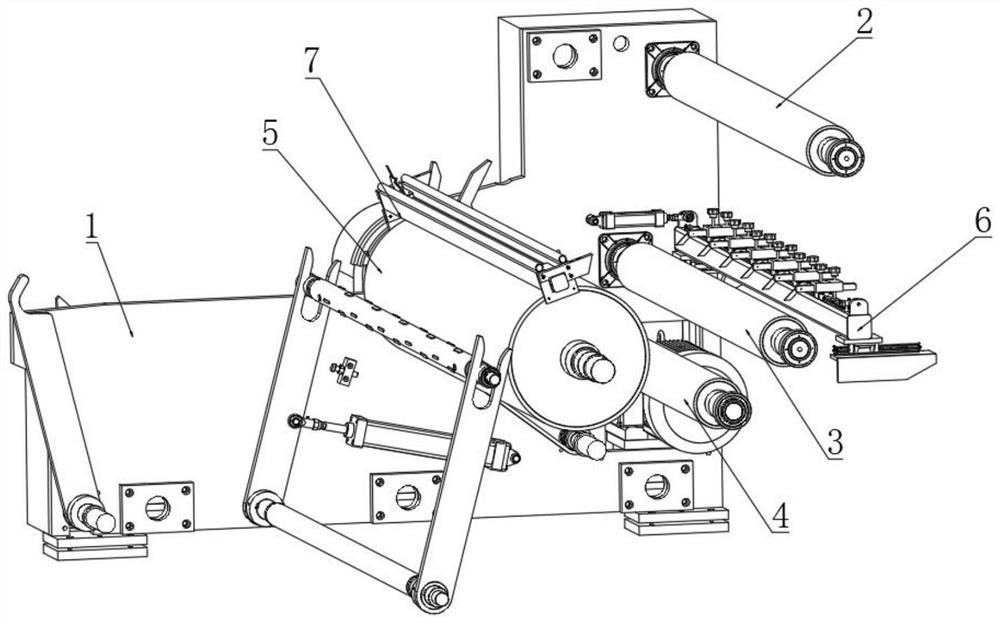

[0053] refer to Figure 2-6, a method for preparing degradable non-woven fabrics, the carding machine 1 in S2 includes a first roll set 2, the first roll set 2 is connected to the inner side of the carding machine 1 in rotation, and the bottom of the first roll set 2 is provided with The second roller group 3, the bottom side of the second roller group 3 is provided with the third roller group 4, the inner middle part of the carding machine 1 is provided with a pressing roller 5, and the top of the pressing roller 5 is provided with a cutting support 6, divided The cutting bracket 6 is connected with a grease-coating bracket 7, and the bottom end of the grease-coating bracket 7 is connected with a grease-coating roller 8 for rolling on the outer side of the corresponding pressing roller 5, and the modified polyester fiber is wound up by the second roller group 3, and the The first roller group 2 and the third roller group 4 wind up the polyester fibers, start the pressing roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com