Sodium alginate/polyethylene glycol blending drug-loading fibre and preparation method and usage thereof

A technology of polyethylene glycol and sodium alginate, which is applied in the fields of alginate artificial filament, wet spinning method, medical science, etc., can solve the problems of high economic cost, elasticity, and insufficient strength, etc., and achieve wide application prospects , excellent mechanical properties, and the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

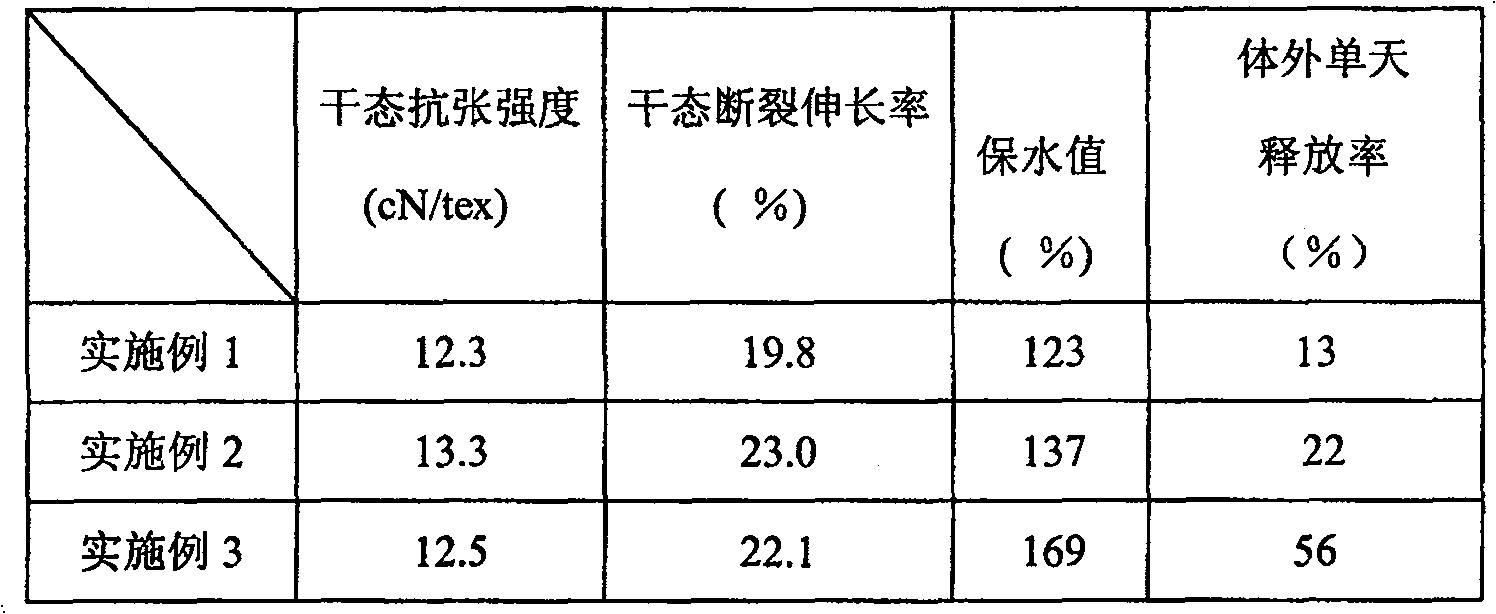

[0010] Embodiment 1: get 45g viscosity-average molecular weight and be 2.0 * 10 6 Sodium alginate was dissolved in 900ml of distilled water to obtain sodium alginate solution; 2g of polyethylene glycol with a viscosity average molecular weight of 6000 was dissolved in 40ml of distilled water to obtain polyethylene glycol solution. The above two solutions are fully mixed with 4g salicylic acid, filtered, and after degassing under reduced pressure, with 5% to 10% (mass ratio) of CaCl 2 The mixed solution of aqueous solution and absolute ethanol in the ratio of 4:6 to 6:4 is the coagulation solution, and the sodium alginate / polyethylene glycol drug-loaded fiber is prepared by solution spinning at room temperature, and the fiber stretch rate is 20%. Its mechanical properties, water retention value and release performance are listed in Table 1.

Embodiment 2

[0011] Example 2: Dissolve 45g of sodium alginate in 900ml of distilled water to obtain a sodium alginate solution; dissolve 4g of polyethylene glycol in 80ml of distilled water to obtain a polyethylene glycol solution. The above two solutions are fully mixed with 4g salicylic acid, filtered, and after degassing under reduced pressure, with 5% to 10% (mass ratio) of CaCl 2 The aqueous solution and absolute ethanol are mixed in a ratio of 4:6 to 6:4 to form a coagulation liquid, and the sodium alginate / polyethylene glycol drug-loaded fiber is prepared at room temperature through a solution spinning method, and the stretching rate of the fiber is 20%. Its mechanical properties, water retention value and release performance are listed in Table 1.

Embodiment 3

[0012] Example 3: 45g of sodium alginate was dissolved in 900ml of distilled water to obtain a sodium alginate solution; 8g of polyethylene glycol was dissolved in 160ml of distilled water to obtain a polyethylene glycol solution. The above two solutions and 4g salicylic acid were fully mixed, filtered, and after degassing under reduced pressure, at room temperature with 5% to 10% (mass ratio) of CaCl 2 The mixed solution of aqueous solution and absolute ethanol in the ratio of 4:6 to 6:4 is the coagulation solution and the sodium alginate / polyethylene glycol drug-loaded fiber is prepared by the solution spinning method, and the stretching ratio of the fiber is 20%. Its mechanical properties, water retention value and release performance are listed in Table 1.

[0013] The solution spinning method used in the above examples is a prior art, which has been described in detail in the patent No. ZL200510018541.8, so the solution spinning method will not be repeated in each embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com