Cable and its preparation method and equipment

A cable and equipment technology, applied in the field of cable and its manufacturing, can solve the problems of non-sealed bonding of polytetrafluoroethylene raw tape and polyimide film, and the inability to realize the seamlessness of the two films, so as to eliminate delamination Sintered tape layer, enhanced resistance to arc propagation, and damage reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

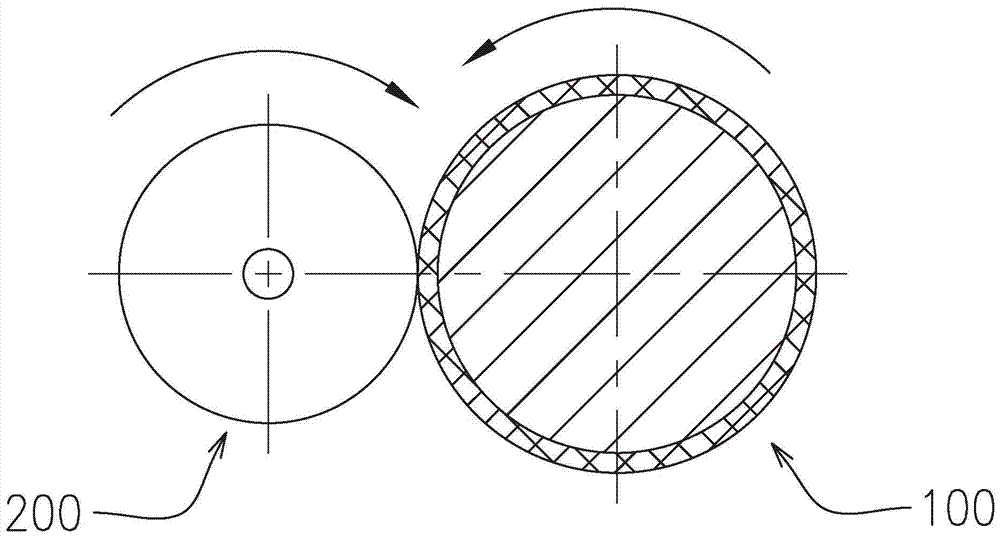

[0115] Taking nickel-plated copper conductor wire as an example, the preparation process of the cable is as follows:

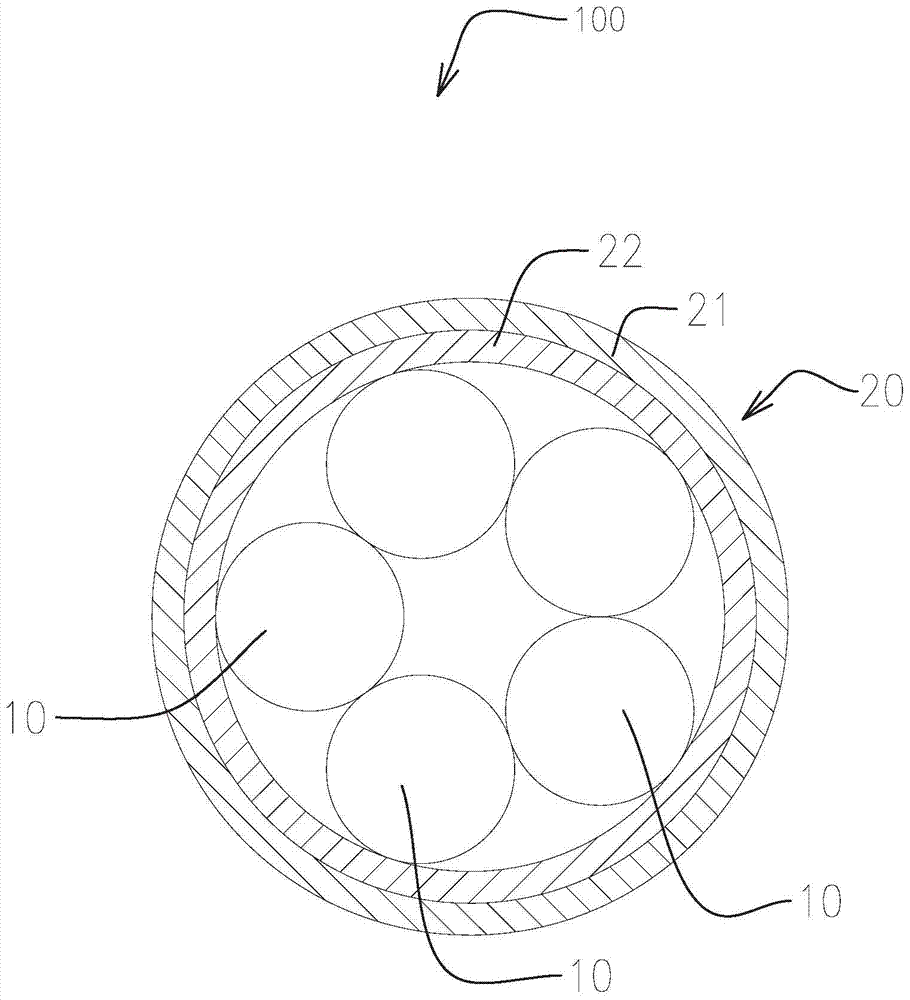

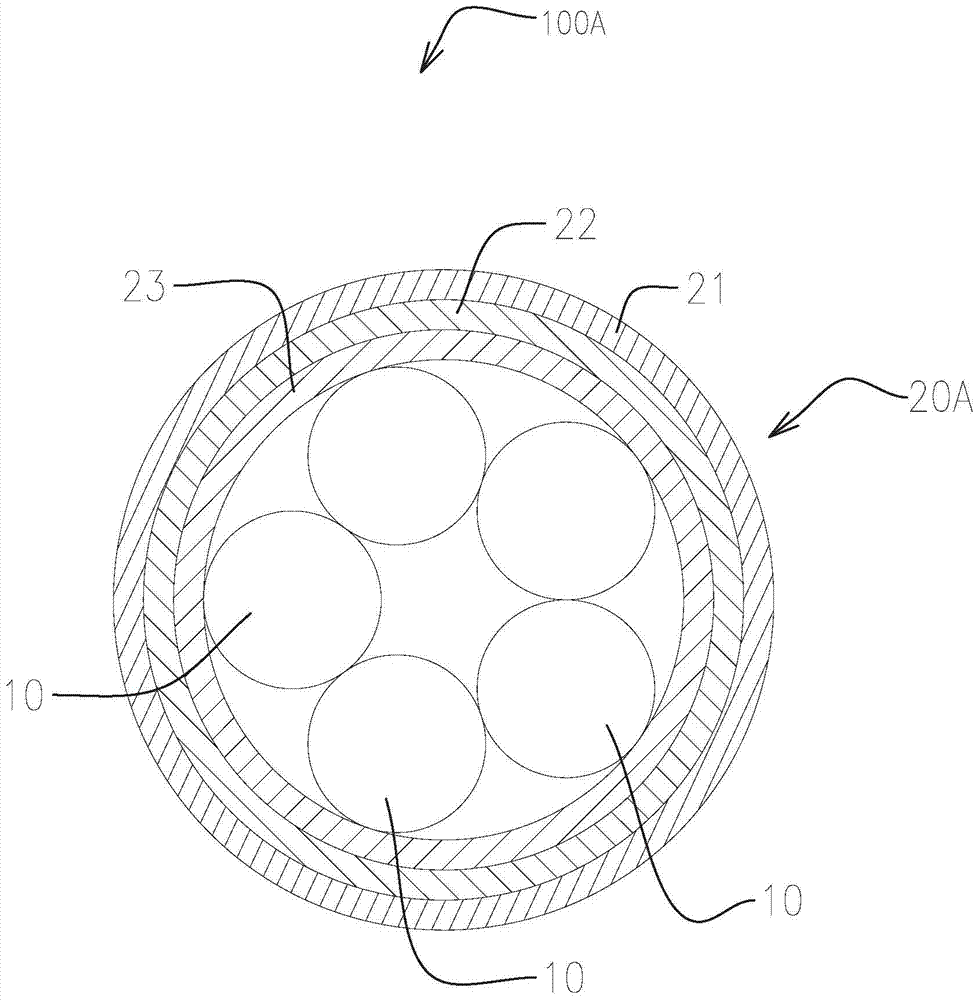

[0116] (1) Wrapping step: the nickel-plated copper conductor is the conductor core, and the third layer (polytetrafluoroethylene microporous film, the second layer (polyimide film) (double-sided coated with fusible PTFE Ethylene emulsion) and the first layer (polytetrafluoroethylene microporous film) to wrap the conductor core, so as to obtain the first-stage cable, wherein the third layer (polytetrafluoroethylene microporous film) has a thickness of 0.010mm and a width of 20mm , the wrapping angle is 35°, the wrapping rate is 50%; the thickness of the second layer (polyimide film) is 0.035mm, the width is 5mm, the wrapping angle is 40°, the wrapping direction is left, and the lapping rate is 50%. The cover rate is 50%; the specific gravity of the meltable polytetrafluoroethylene emulsion is 2.12g / cm3, the elongation at break is 300%, the tensile strength is 3...

Embodiment 2

[0121] Taking nickel-plated copper alloy conductor wire as an example, its preparation process is as follows:

[0122] (1) Wrapping step: the nickel-plated copper alloy conductor is the conductor core, and the third layer (polytetrafluoroethylene microporous film, the second layer (polyimide film) (double-sided coated with fusible polytetrafluoroethylene film) Fluoroethylene emulsion) and the first layer (polytetrafluoroethylene microporous film) wrap the conductor core to obtain the first-stage cable, in which the third layer (polytetrafluoroethylene film) has a thickness of 0.055mm and a width of 75mm. The wrapping angle is 45°, the covering rate is 40%; the thickness of the second layer (polyimide film) is 0.045mm, the width is 25mm, the wrapping angle is 50°, the winding direction is left, and the covering rate is 35%; Melting polytetrafluoroethylene emulsion has a specific gravity of 2.17g / cm3, an elongation at break of 300%, a tensile strength of 30N / mm2, a static elasti...

Embodiment 3

[0127] Taking tinned copper alloy conductor wire as an example, its preparation process is as follows:

[0128] (1) Wrapping step: the tinned copper alloy conductor is the conductor core, and the third layer (polytetrafluoroethylene microporous film, the second layer (polyimide film) (double-sided coated with fusible polytetrafluoroethylene film) Fluoroethylene emulsion) and the first layer (polytetrafluoroethylene microporous film) wrap the conductor core to obtain the first-stage cable, in which the third layer (polytetrafluoroethylene film) has a thickness of 0.080mm and a width of 100mm. The wrapping angle is 70°, and the wrapping coverage rate is 65%; the thickness of the second layer (polyimide film) is 0.05mm, the width is 50mm, the wrapping angle is 50°, the wrapping direction is left, and the wrapping coverage rate is 70%; The specific gravity of the meltable polytetrafluoroethylene emulsion is 2.15g / cm3, the elongation at break is 300%, the tensile strength is 30N / mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| bubble point pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com