Multi-nozzle balanced flow meter

A balanced flow and multi-nozzle technology, which is applied to the volume/mass flow generated by mechanical effects, and the detection of fluid flow by measuring pressure difference, etc., can solve the problem of limited flow measurement range, high installation conditions, narrow measurement range, etc. problem, to achieve the effect of shortening requirements, saving operating energy costs, reducing turbulent shear force and eddy current formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

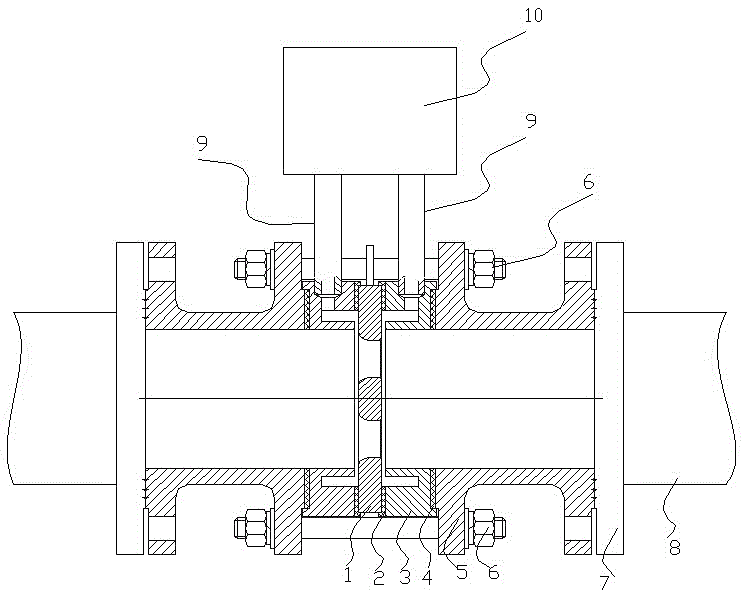

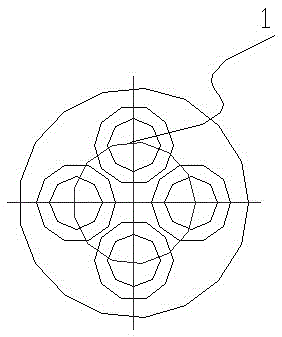

[0022] Such as Figure 1-2 As shown, the multi-nozzle balanced flowmeter includes a multi-nozzle balanced circular plate 1, an annular chamber 3, a connecting pipe 5 with a flange, a straight pipe section 8, a pressure-taking pipe 9 and a sensor 10. On the multi-nozzle balanced circular plate 1 A plurality of nozzles are regularly and uniformly arranged, and positioning grooves and pressure-taking holes are set on the ring chamber 3. The multi-nozzle balance circular plate 1 is clamped between the two ring chambers 3 through the positioning grooves. The connecting pipes 5 of the flanges are respectively located outside the two annular chambers 3 and are connected into one body by stud bolts 6. The straight pipe section 8 is installed on the connecting pipes 5 with flanges through the connecting flange 7, and the pressure-taking holes of the annular chambers 3 are welded. The pressure-taking pipe 9 and the sensor 10 welded on the pressure-taking pipe 9 form a multi-nozzle balan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com