Automatic assembly line for LED energy-saving lamp

A technology for LED energy-saving lamps and assembly lines, which is applied to machines with sequential working positions, etc., can solve the problems of low production efficiency and high labor intensity of workers, so as to improve production efficiency, reduce labor intensity and labor costs, and improve equipment operation. smart effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

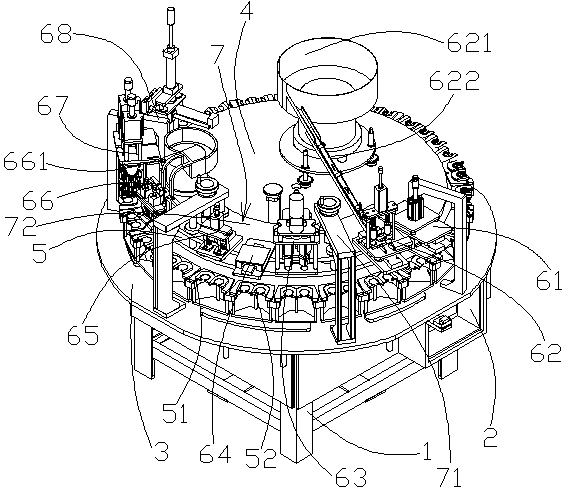

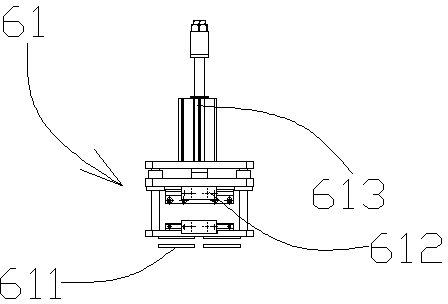

[0025] see figure 1 , an automatic assembly line for LED energy-saving lamps, including a frame 1, an electric control box 2, a disc bottom plate 3, a disc upper panel 4, a rotating aluminum disc 5, a center line assembly 61, a pre-installed threaded lamp cap assembly 62, a screw thread The lamp cap assembly 63, the lighting test assembly 64, the centerline cutting assembly 65, the middle nail assembly 66, the threaded lamp cap riveting assembly 67 and the unloading lamp assembly 68, the electric control box 2 is placed on the frame 1, and the The disc base plate 3 is arranged directly above the frame 1, the rotating aluminum disc 5 is installed and placed on the disc base plate 3 through a rotating assembly, and the center line assembly 61, pre-installed threaded lamp cap assembly 62, screw The threaded lamp cap assembly 63, the lighting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com