Production line of water fountain metal plate shells

A production line, machine sheet metal technology, applied in the direction of metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of low life of plastic shells, low yield of stainless steel arc bending, etc., to improve production efficiency and ensure stamping quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiments of the present invention will be described in detail below.

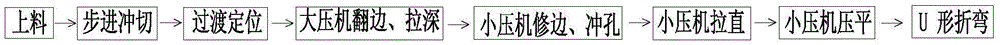

[0041] like figure 1 As shown, the present invention discloses a water dispenser sheet metal shell production line, comprising:

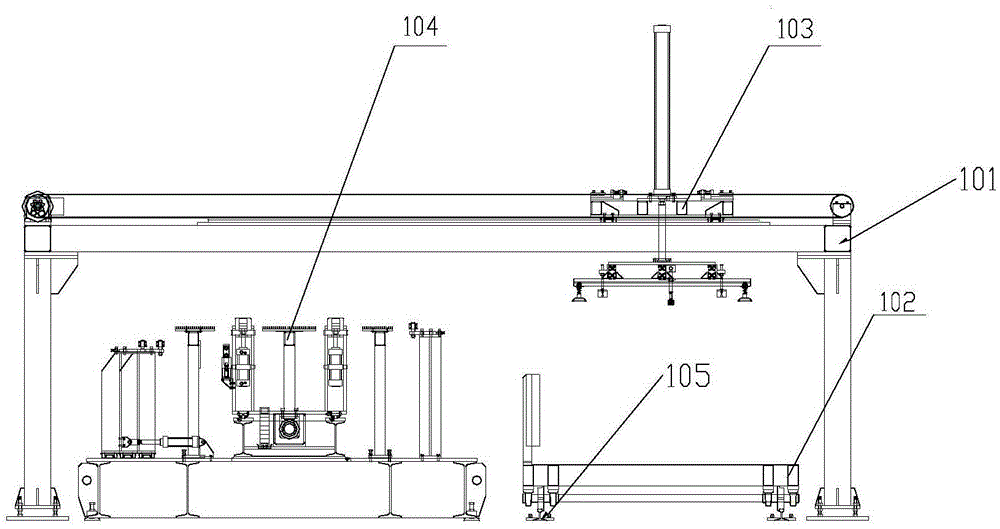

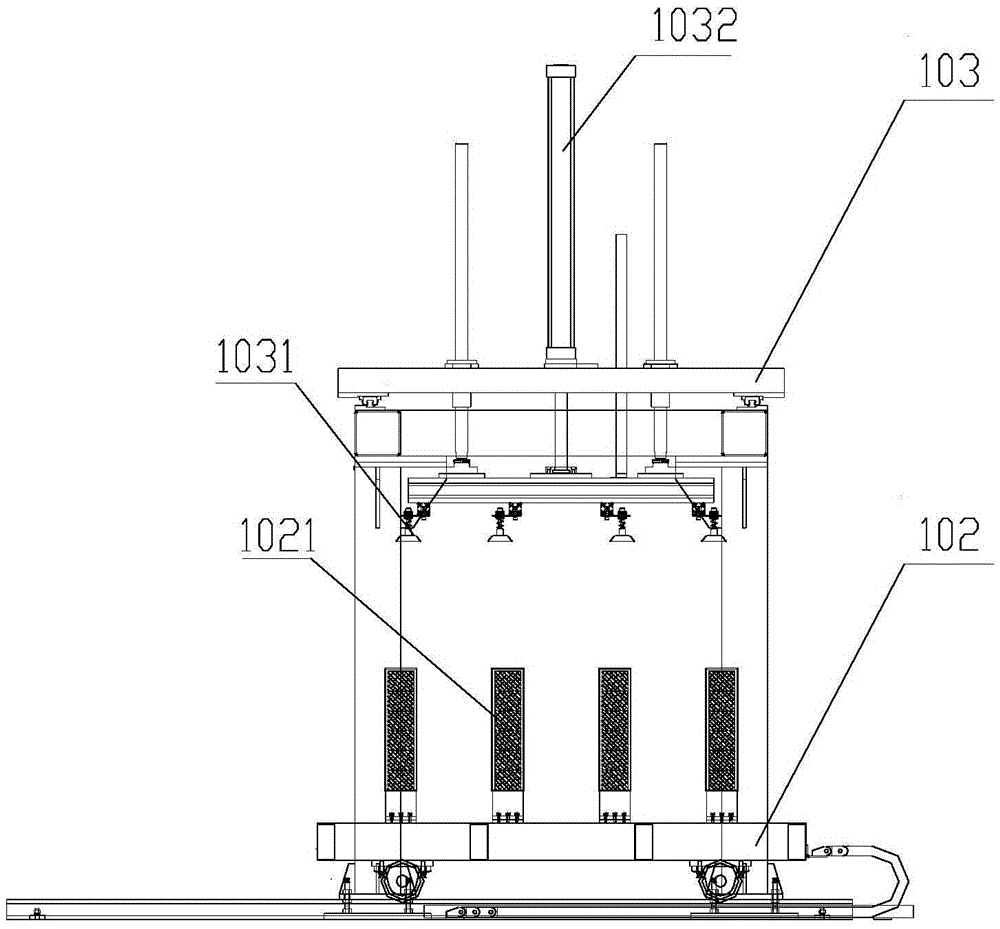

[0042] feeder, such as figure 2 and image 3 As shown, it includes a loading rack 101, a stacker trolley 102, a vacuum suction transfer robot 103 and a positioning table 104. The vacuum suction transfer robot 103 is installed on the loading rack 101, the positioning table 104 and the stacker trolley 102 is arranged under the loading frame 101, and the body of the stacking trolley 102 adopts a welded structure; the stacking trolley 102 is provided with a guide rail 105, and the stacking trolley 102 is also provided with a material distribution mechanism 1021, which naturally separates the sheets, and the vacuum The suction and transfer manipulator 103 uses the vacuum suction cup 1031 to absorb the sheet material, and uses the air cylinder 1032 to lift the sheet mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com