Rail-Based Climbing Robot

A technology of robots and guide rails, applied in the field of climbing robots based on guide rails, can solve problems such as low safety, cable falling, and unfavorable escape, and achieve the effects of wide application range, convenient installation, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

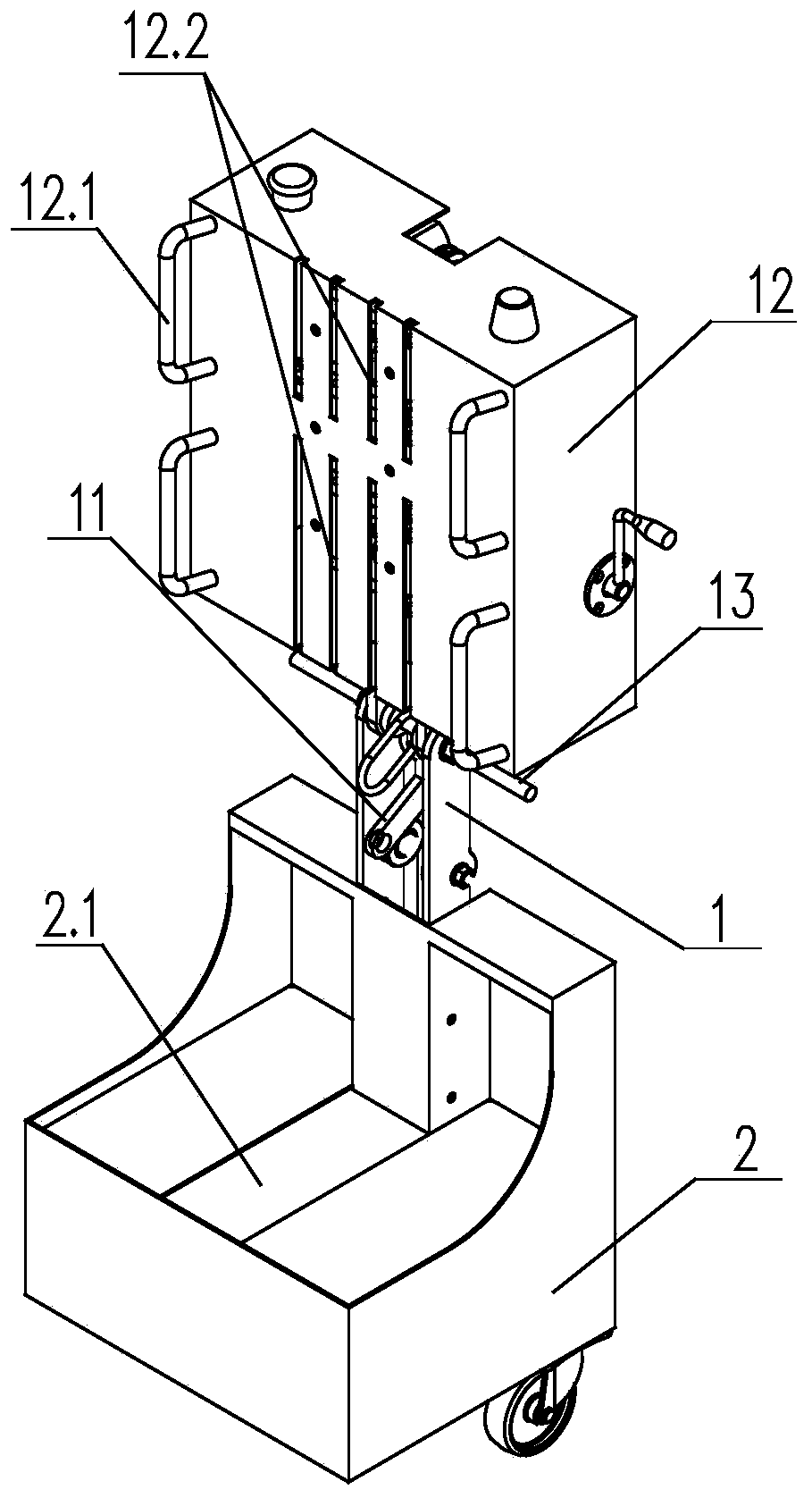

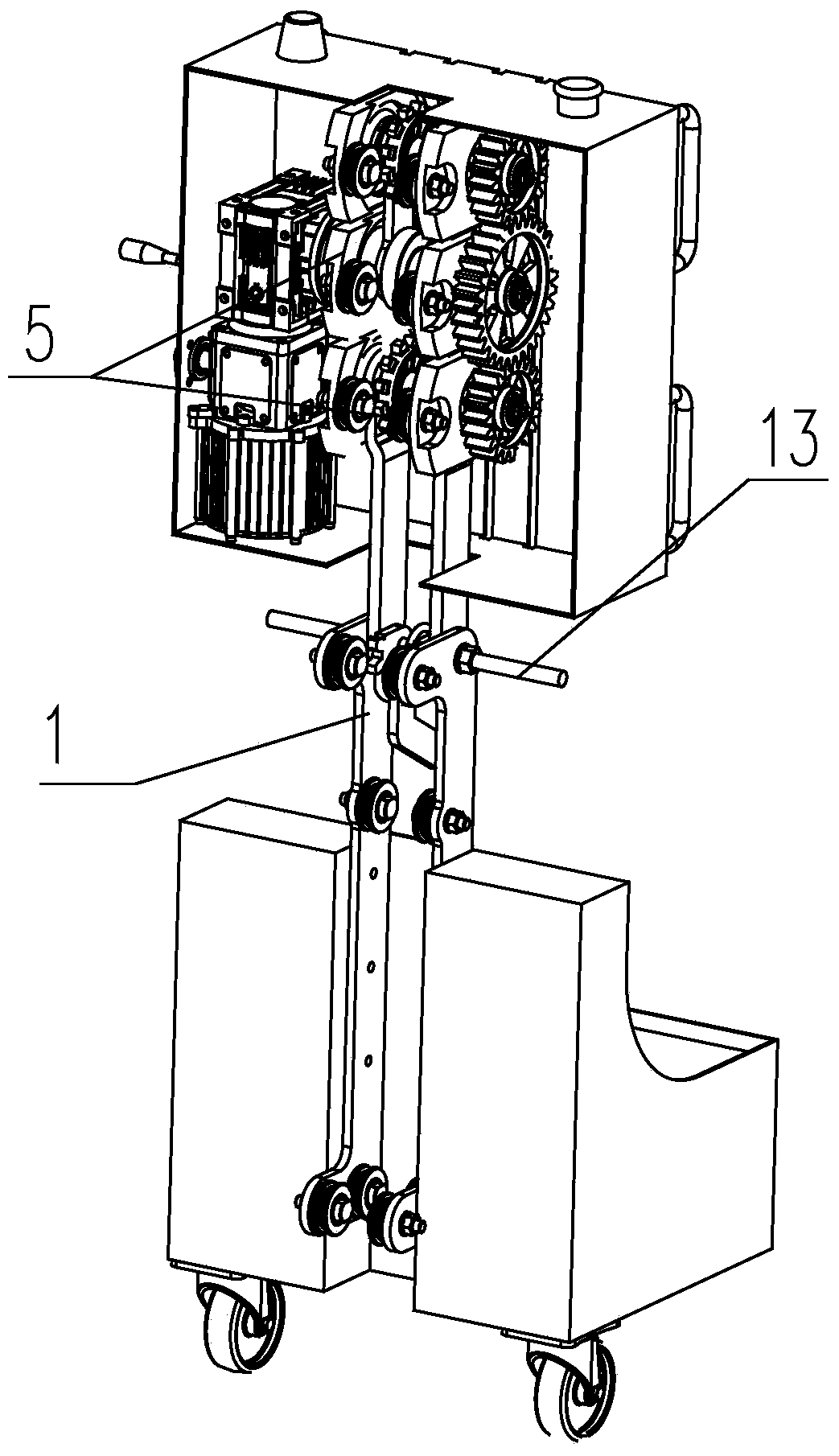

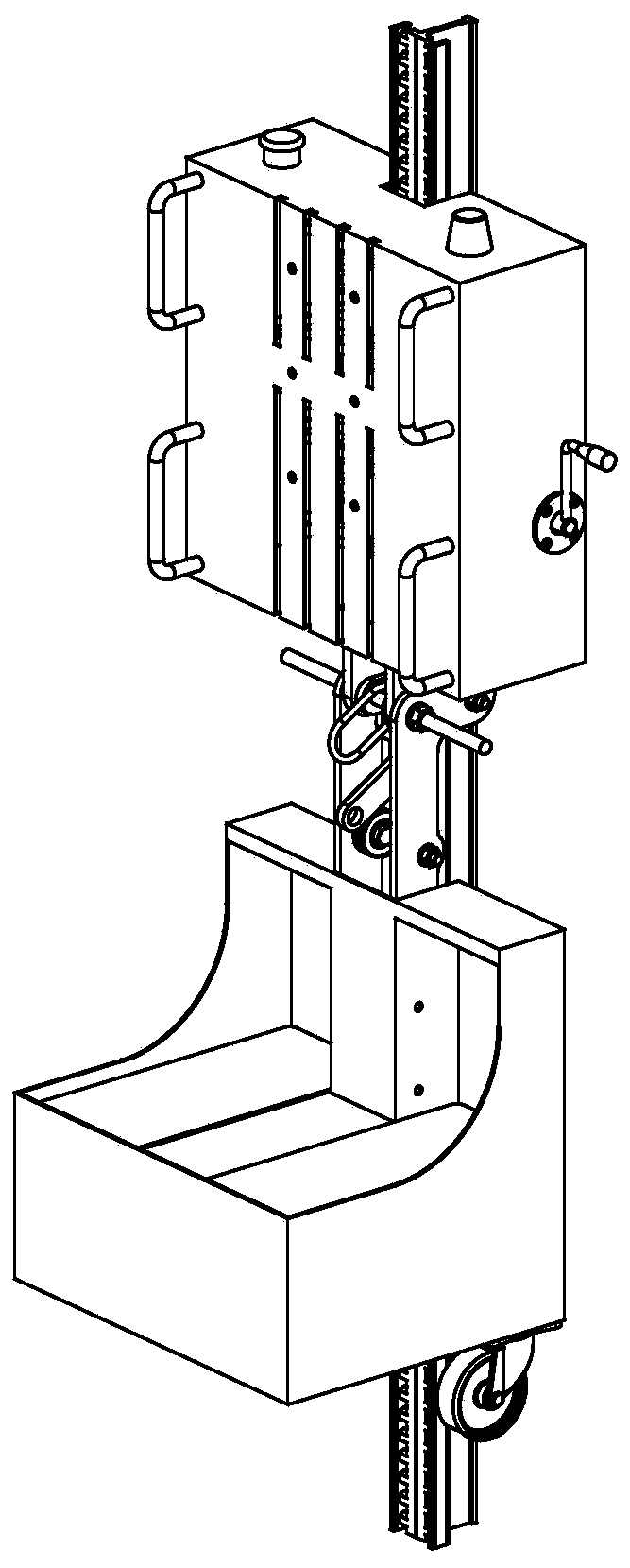

[0028] refer to Figure 1-Figure 8 A climbing robot based on a guide rail is shown, comprising a mounting frame 1, on which a carrier 2, a power assembly 3, a lifting assembly 4 and an electric control assembly are arranged, and the power assembly 3 and the lifting assembly 4 are connected to the carrier 2 Realize linkage in the same direction, the carrier 2 is provided with a battery containing groove 2.1. The electric control component is electrically connected with the power component 3, and the power component 3 drives the lifting component 4 to move up and down; the lifting component 4 includes a driving part 4.1 connected as one, an upper driven climbing part 4.2 and a lower driven climbing part 4.3, the backs of the driving part 4.1, the upper driven climbing part 4.2 and the lower driven climbing part 4.3 are all hinged with limited rolling parts 5; the upper driven climbing part 4.2 and the lower driven climbing part 4.3 are equipped with Climbing sprocket 6; the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com