Splicable tray

A pallet and pallet foot technology, applied in the field of handling workpieces, can solve the problems of inability to quickly assemble, time-consuming and laborious, etc., and achieve the effects of easy storage and arrangement, convenient use, and improved splicing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

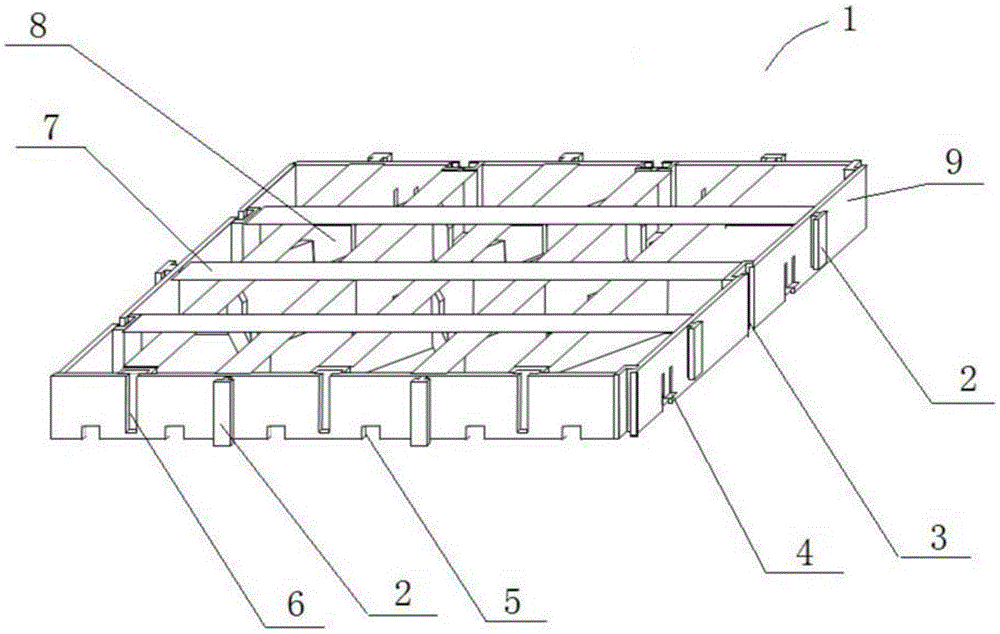

[0045] Such as Figure 1 to Figure 5 As shown, a pallet that can be spliced includes: a pallet unit 1, the side of the pallet unit 1 is also provided with a first hook 4 and a first hook hole 5 respectively, and the first hook 4 and the first hook hole 5 are connected to each other. Cooperating arrangement; the side of the tray unit 1 is respectively provided with a card slot 6 and a card hole 3 , and a card bar 2 cooperating with the card slot 6 and the card hole 3 respectively.

[0046] Specifically, both the first hook 4 and the first hook hole 5 are disposed at the bottom of the tray unit.

[0047] Specifically, the cross-sections of the slot 6 and the hole 3 are both T-shaped.

[0048] Specifically, the tray unit 1 is in the shape of a polygon such as a square, a rectangle, a triangle, or a hexagon.

[0049] Preferably, the tray unit 1 is rectangular. One side of the tray unit 1 is provided with a clip bar 2, two clip slots 6 and four first hook holes 5, wherein the ...

no. 2 example

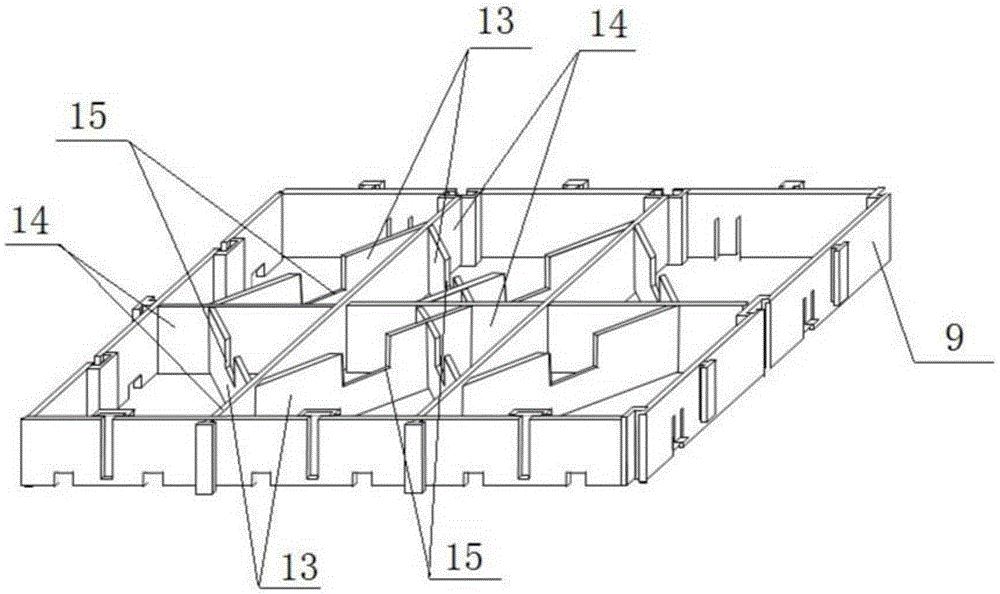

[0069] Such as Figure 6 and Figure 7 As shown, a pallet that can be spliced includes: a pallet unit 1, the side of the pallet unit 1 is also provided with a first hook 4 and a first hook hole 5 respectively, and the first hook 4 and the first hook hole 5 are connected to each other. Cooperating arrangement; the side of the tray unit 1 is respectively provided with a card slot 6 and a card hole 3 , and a card bar 2 cooperating with the card slot 6 and the card hole 3 respectively. Both the first hook 4 and the first hook hole 5 are disposed on the bottom of the tray unit. The cross-sections of the slot 6 and the hole 3 are both T-shaped.

[0070] The tray unit 1 includes several reinforcing ribs 8 and a frame 9, the several reinforcing ribs 8 are arranged inside the frame 9, and the card groove 6, the card hole 3, the first hook 4 and the first hook hole 5 are all arranged on the frame 9;

[0071] Reinforcing rib 8 comprises four the 3rd reinforcing plates 21 and four 4t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com