Multifunctional composite bottle cap

A multi-functional, bottle cap technology, applied in the field of containers, can solve the problems of single cap structure, inability to smoke, no automatic opening or closing, etc., and achieve the effect of portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

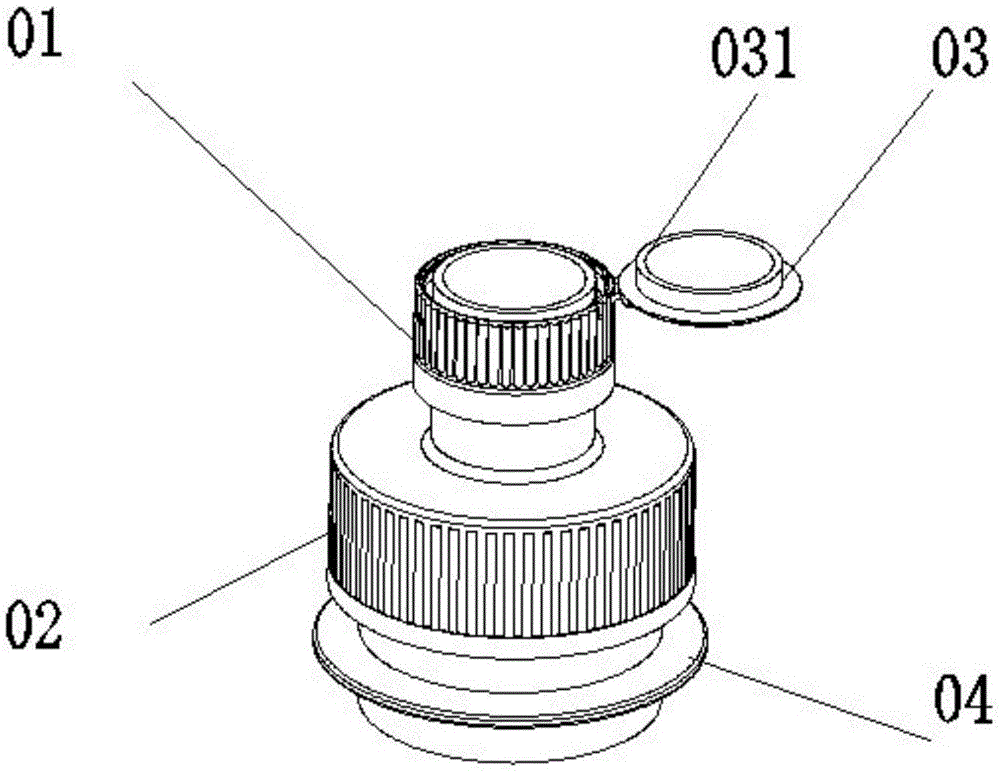

[0029] Embodiment one: refer to Figure 1-Figure 3 As shown: a multi-functional composite bottle cap is designed, including a lower cap body 02 screwed on the container mouth 04, and an upward protrusion is integrally formed on the top of the lower cap body 02, and its diameter is smaller than that of the lower cap body 02 outer diameter of the pipe body; the outer circle of the pipe body is provided with a thread 06, and an upper cover 01 is screwed on the thread, and the top of the upper cover 01 is provided with a When covering, the flat cover 03 that can be pushed back, the edge of the flat cover 03 that can be pushed back is connected with the edge of the upper cover through an integrally formed tie belt 031 .

[0030] Rotate the upper cover 01 downward, and the flat cover 03 on the top will be pushed away by the upper edge of the tube body; at this time, you can suck through the inner hole of the tube body; due to the function of the elastic valve, if you need to drink, ...

Embodiment 2

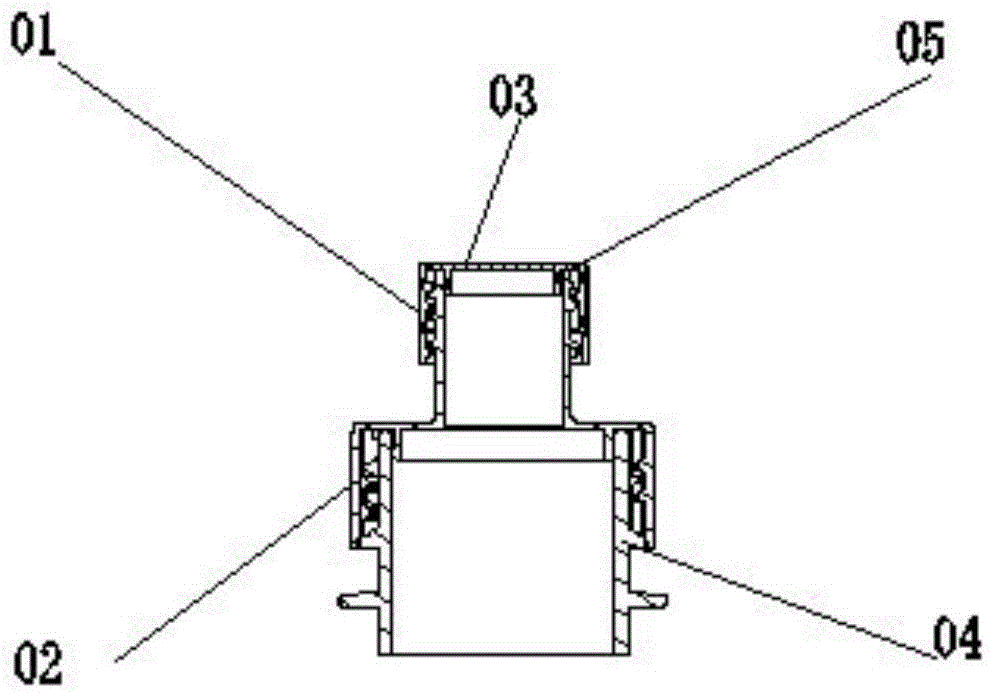

[0031] Embodiment two: refer to Figure 4-Figure 8 Shown: a multi-functional composite bottle cap is designed, including a lower cap body 02 screwed on the container mouth, and an upward protrusion is integrally formed on the top of the lower cap body 02, and its diameter is smaller than the outer diameter of the lower cap body There is a card seat 07 with only a through hole 072 in the upper ferrule of the inner hole of the tube body; an annular card slot 071 is provided in the through hole 072 of the card seat, and a can be clamped in the card slot The elastic valve 08 that is automatically opened by suction or pressure; the valve 08 has an elastic membrane that arches downward, and one or more scratches that can be automatically opened by suction or pressure are opened on the elastic membrane; A thread 06 is provided on the outer circle, and an upper cover 05 is screwed on the thread. The top of the upper cover 05 is provided with a flat cover 06 that can be opened by turni...

Embodiment 3

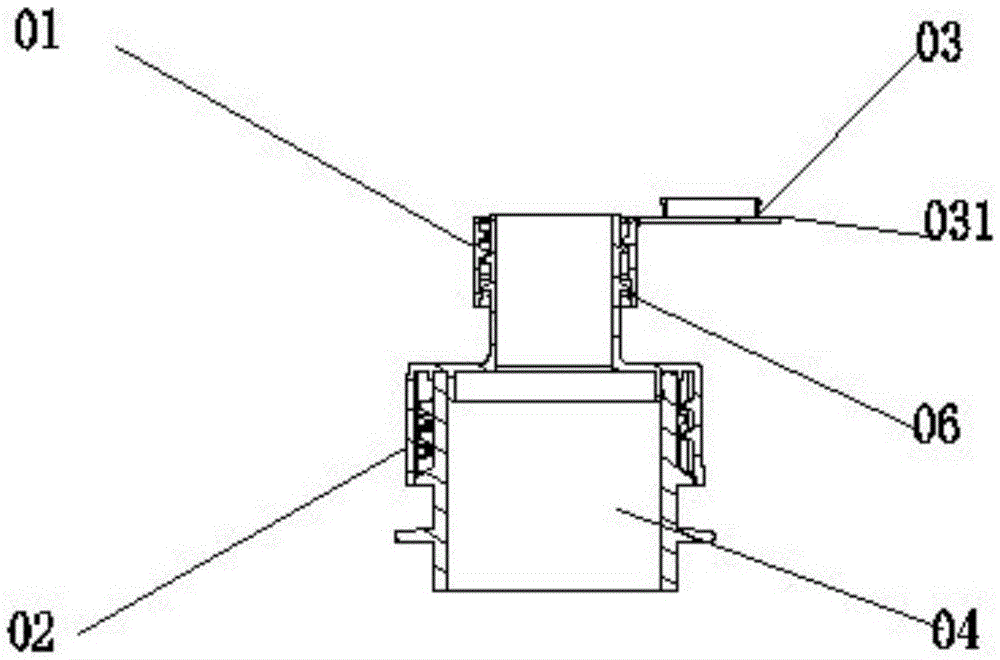

[0033] Embodiment three: refer to Figure 9-Figure 10 As shown: a multi-functional composite bottle cap is designed, including a lower cap body 02 screwed on the container mouth, and an upward protrusion is integrally formed on the top of the lower cap body 02, and its diameter is smaller than the outer diameter of the lower cap body A pipe body 05; a card seat 07 is integrally formed on the upper part of the inner hole of the tube body; an annular card slot 072 is provided in the through hole of the card seat 07, and an annular card slot 072 is installed in the card slot, which can be automatically activated by suction or pressure. The opened elastic valve 014; the valve 08 has an elastic film arched downward, and one or more scratches that can be automatically opened by suction or pressure are opened on the elastic film; screw thread, an outer snap ring is provided on the pipe body 05 at the lower part of the thread, an anti-theft ring 01 is clamped on the snap ring, and an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com