Electronic expansion valve with double throttling function

An electronic expansion valve, double throttle technology, applied in the direction of sliding valve, valve details, valve device, etc., can solve the problem of the influence of electronic expansion valve work reliability, and achieve the effect of improving adjustability, compact structure and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

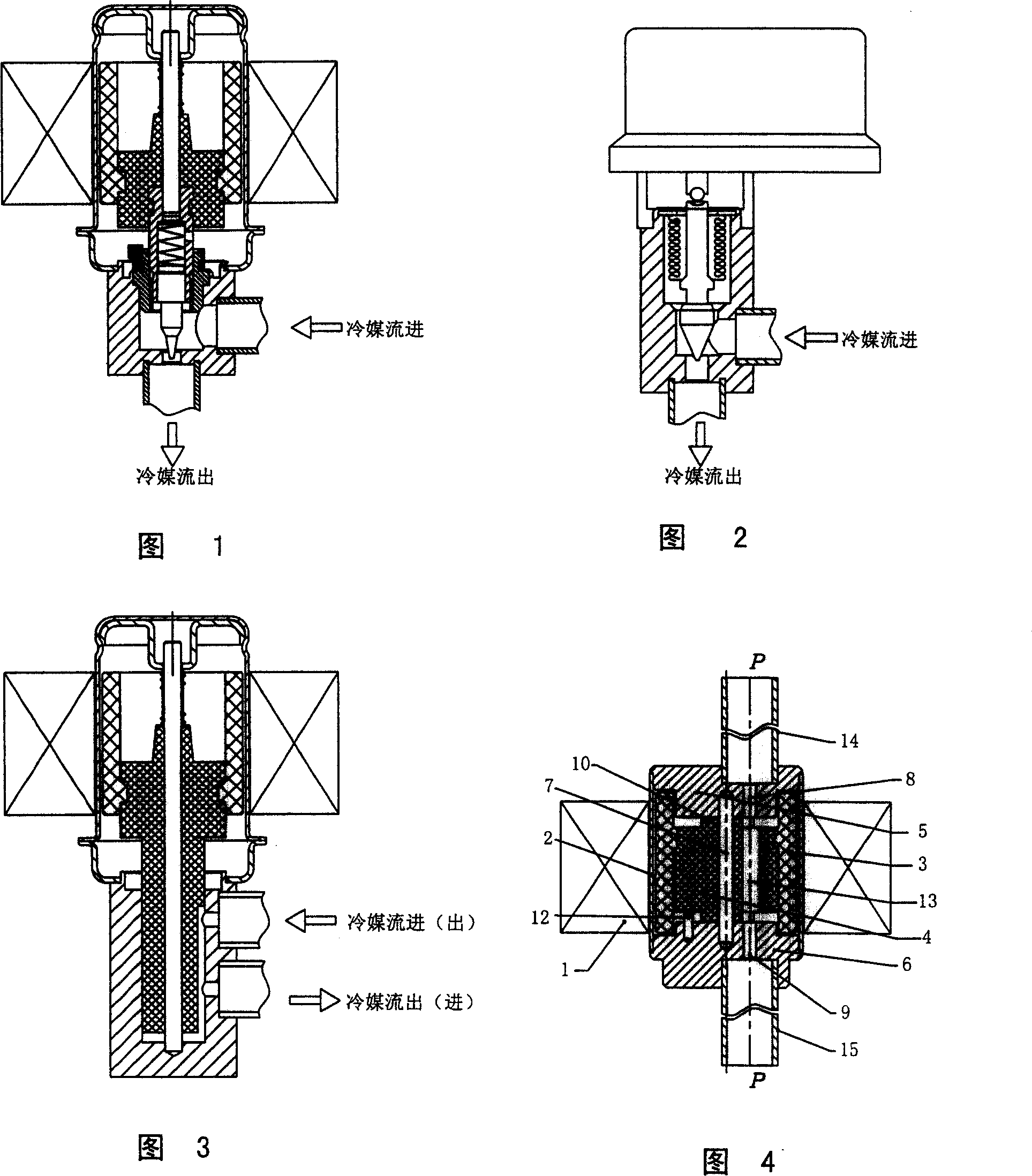

[0033] As shown in Figure 4-9, the electronic expansion valve with double throttling function includes a coil 1 and a valve body connected to it. The valve body includes a sleeve 2, a magnetic rotor 3 placed in the sleeve 2, and a The plastic rotor 4 in the magnetic rotor 3 and the upper and lower end caps 5, 6 welded to the two ends of the sleeve 2 are provided with a central shaft 7 on the plastic rotor 4, and the two ends of the central shaft 7 are respectively positioned on the upper and lower end caps 5, 6, the upper and lower end caps 5, 6 are respectively provided with upper and lower valve ports 8, 9 which deviate from the central axis 7 and have the same diameter.

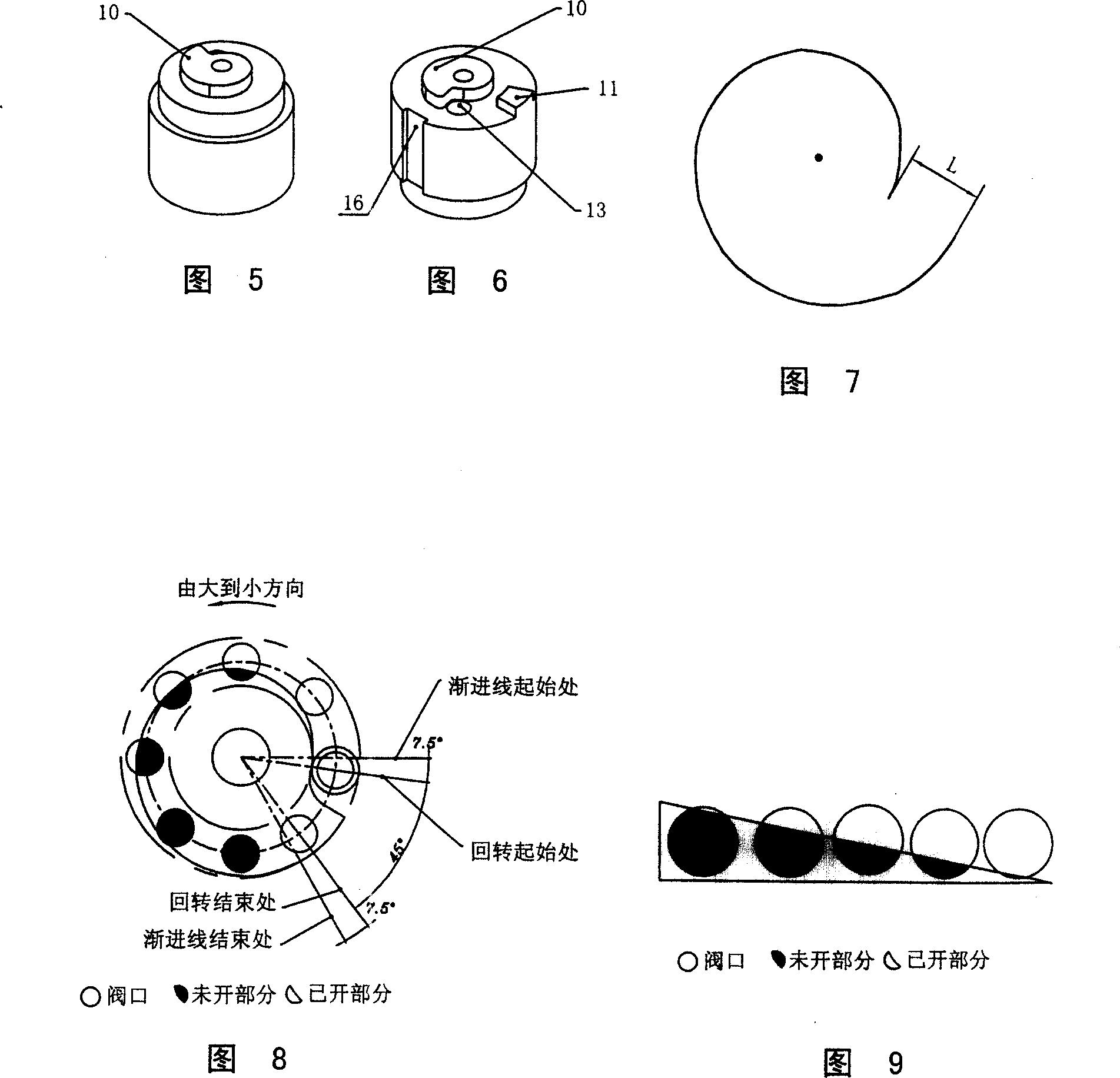

[0034]A flow regulating cam 10 is respectively arranged on both ends of the plastic rotor 4, and the upper and lower cams have the same shape and opposite directions. The edge profile of the cam used to regulate the flow is composed of three plane progressive spirals (see Figure 7). The angle of rotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com